Automatic powder feeding device of powder bucket

A powder bucket and powder feeding technology, which is applied in the directions of transportation and packaging, conveying bulk materials, conveyors, etc., can solve the problems of wasting powder, being susceptible to moisture, and having high powder content, and achieve the effect of improving measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

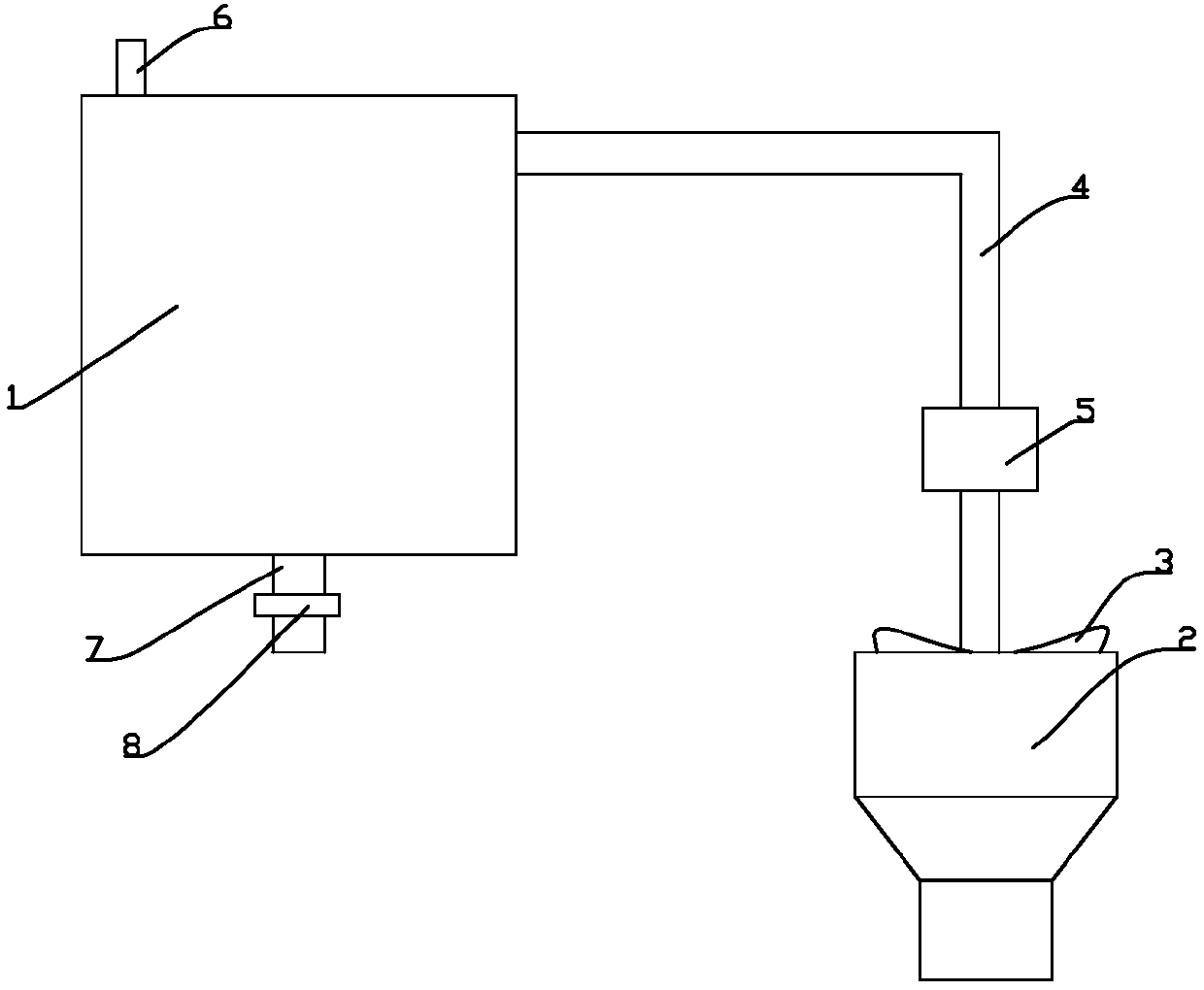

[0014] Such as figure 1 As shown, an automatic powder feeding device for a powder bucket includes a cylindrical powder bucket 1 and a powder bag placement bucket 2, and a powder bag 3 containing powder is placed in the powder bag placement bucket 2, and the powder bucket 1 The upper part is connected with a powder suction pipe 4, and the other end of the powder suction pipe 4 extends into the powder bag 3, and the powder suction pipe 4 is provided with a pneumatic suction device for sucking the powder from the powder bag 3 into the powder barrel 1. Powder pump 5, the top of the powder bucket 1 is provided with a radar level gauge 6, the distance from the radar level gauge 6 to the inner side wall of the powder bucket 1 is 1 / 6 of the inner diameter of the powder bucket 1, and the radar level gauge 6 is 1 / 6 of the inner diameter of the powder bucket 1. Both the position gauge 6 and the pneumatic powder suction pump 5 are connected with a controller.

[0015] The powder bag plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com