Three-point full-automatic high-speed high-precision punching machine and silicon steel sheet blanking production line

A fully automated, high-precision technology, used in forming tools, connecting components, mechanical equipment, etc., can solve the problems affecting the magnetic field strength and magnetic field uniformity of the magnet, the reduction of the core lamination coefficient, and the small radius of curvature of the iron core. The effect of good magnetic field uniformity, reducing welding deformation and reducing the difficulty of lamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

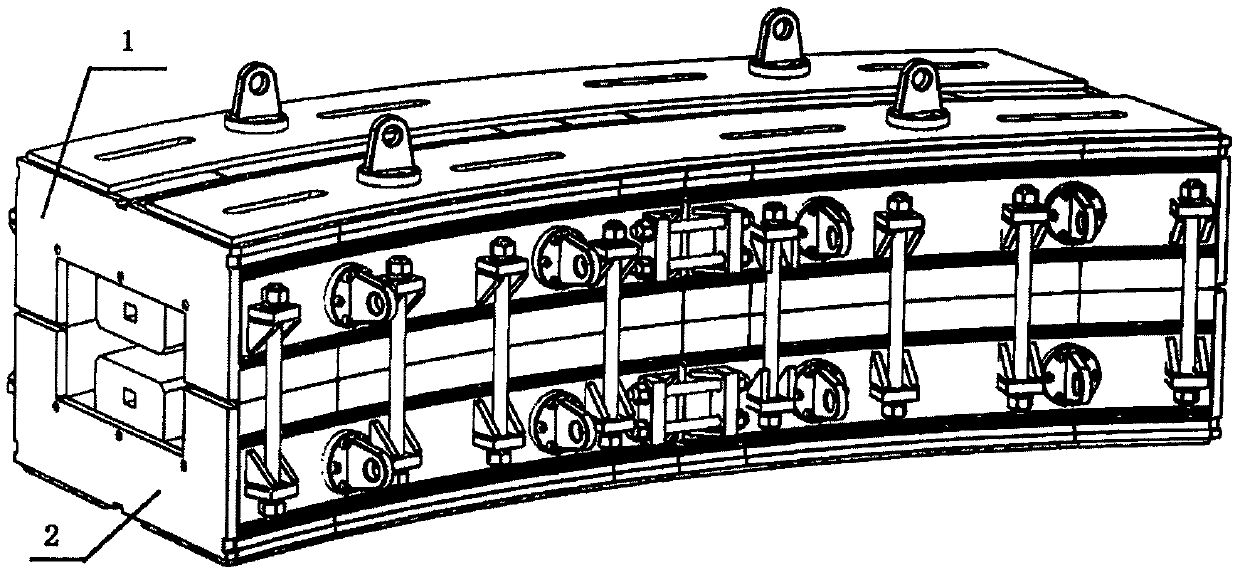

[0019] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

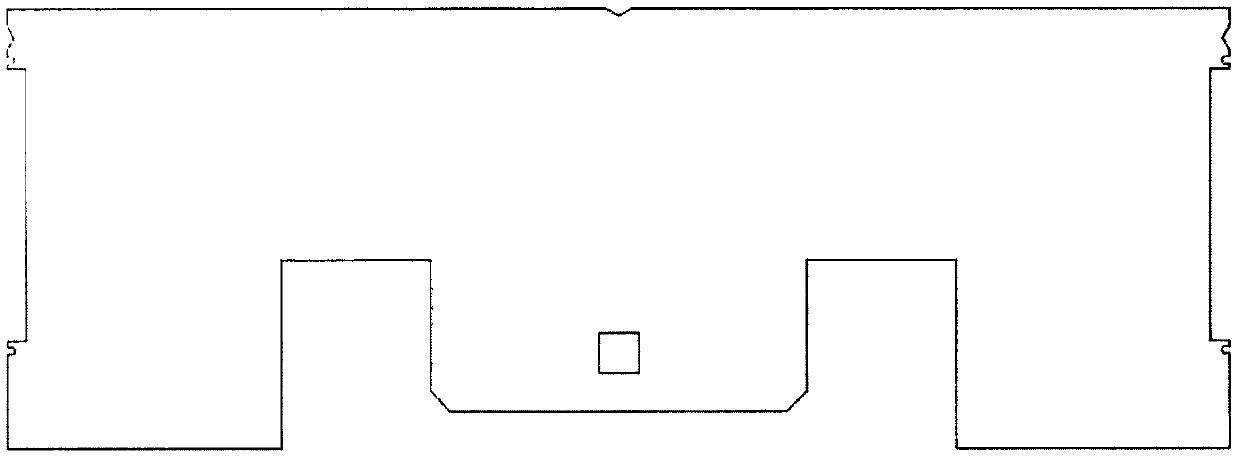

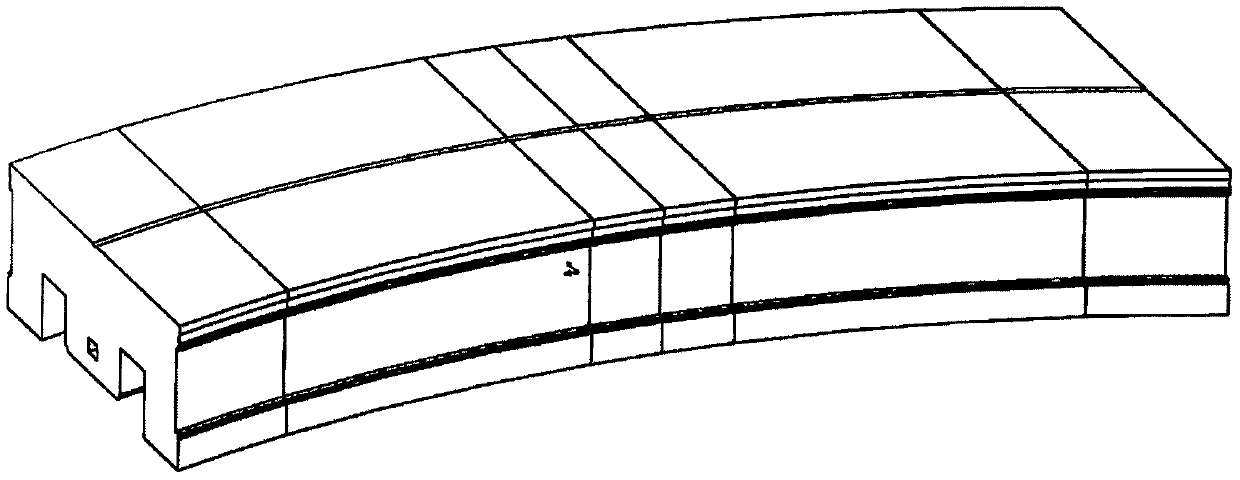

[0020] Such as Figures 1 to 3 As shown, the three-point fully automated high-speed high-precision punch press and silicon steel sheet blanking production line has an H-shaped upper and lower symmetrical structure of its iron core, which is characterized by the following steps:

[0021] (1) Punch the silicon steel sheet with a thickness of 0.5mm into the shape of the iron core punching sheet on a precision punching machine, and use a three-coordinate measuring instrument to check the size. The length dimension error is not greater than 0.05mm, and the height direction dimension error is not greater than 0.04mm, the thickness error is not more than 0.03mm;

[0022] (2) Evenly coat the surface of the qualified iron c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thrust | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com