Method and device for creating a continuous carrier gas/steam vapour flow

A technology for carrying gas and mixed airflow, which is applied in the direction of gas/steam and solid mixing, gas and gas/steam mixing, and mixing methods, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

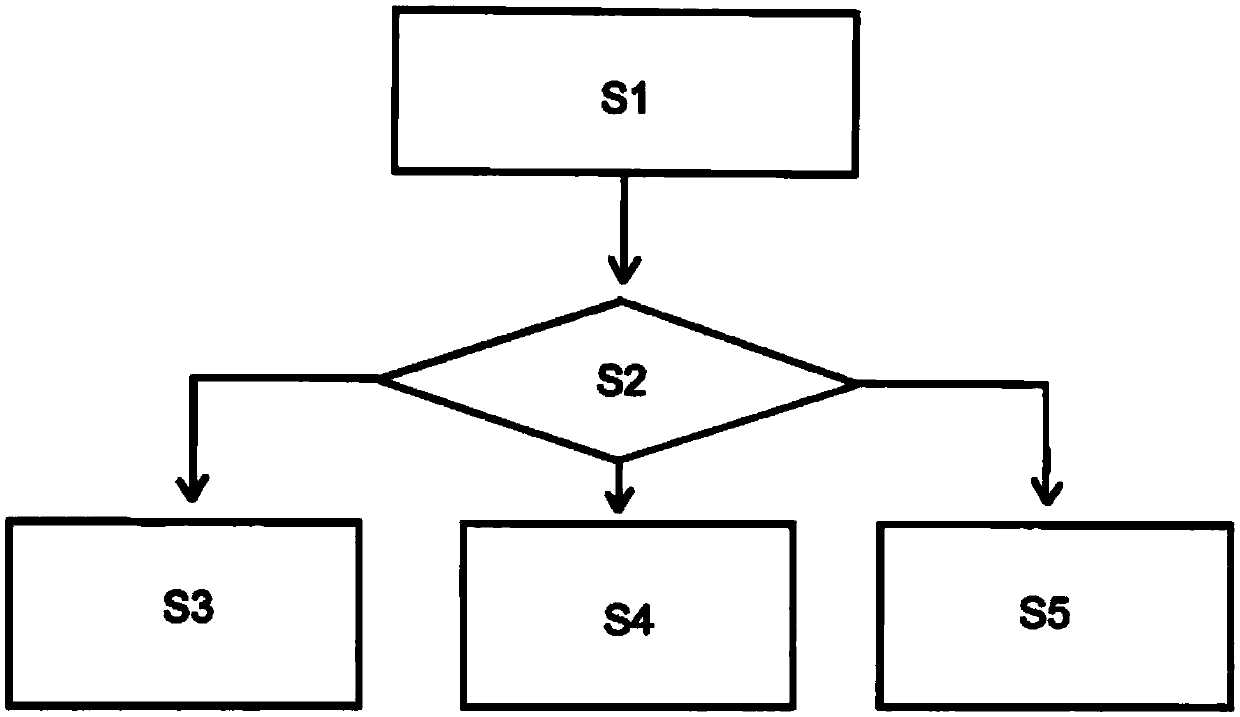

[0068] figure 1 The main steps of the method for generating a continuous flow of carrier gas / steam mixture are shown.

[0069] In step S1, the target concentration of the vapor-like component (steam fraction in the carrier gas / steam mixture) is defined, which can be specified, for example, directly by the user or in an automatically running "concentration program" which determines the difference between the target concentration and Time-dependent (advance via user input) curves. Preferably, in step S1 it is also possible to define the total flow rate of the carrier gas / steam mixture (e.g. mass per time unit or volume per time unit), or equivalently define the mass flow rate of the carrier gas fraction and the vapor fraction . The magnitude of the latter flow rate can likewise be predetermined, for example by means of the concentration program described.

[0070] In step S2, judge the current preset target concentration to see whether the target concentration is zero, relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com