Self-detection and self-repair method of broken line in capacitive fingerprint collection system

A fingerprint collection and capacitive technology, which is applied in the field of self-detection and self-repair of bad lines, can solve the problems of "tablet consistency of semiconductor devices, broken lines of capacitive fingerprint modules, and failure to collect images normally, etc., and achieve good repair effect , high applicability, and small amount of algorithms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In conjunction with the accompanying drawings, the present invention is described in detail, but the scope of protection of the present invention is not limited to the following examples, that is, all simple equivalent changes and modifications made with the patent scope of the present invention and the content of the specification are still patents of the present invention. covered.

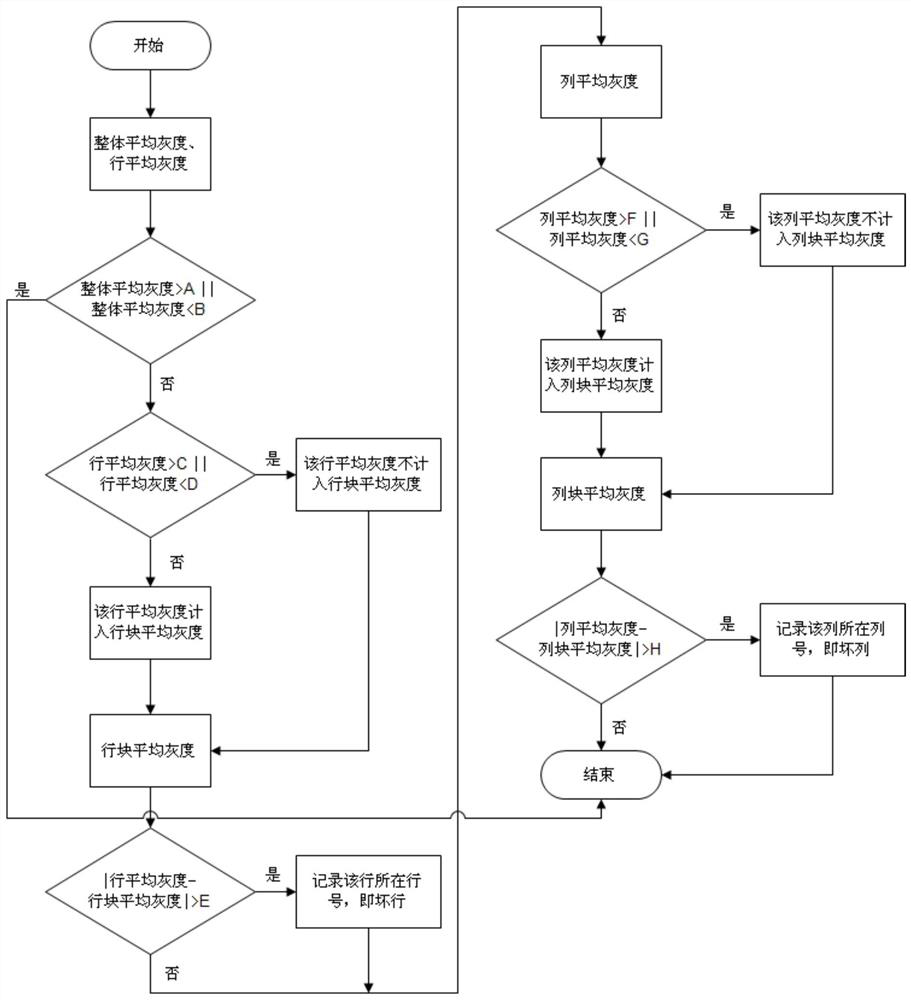

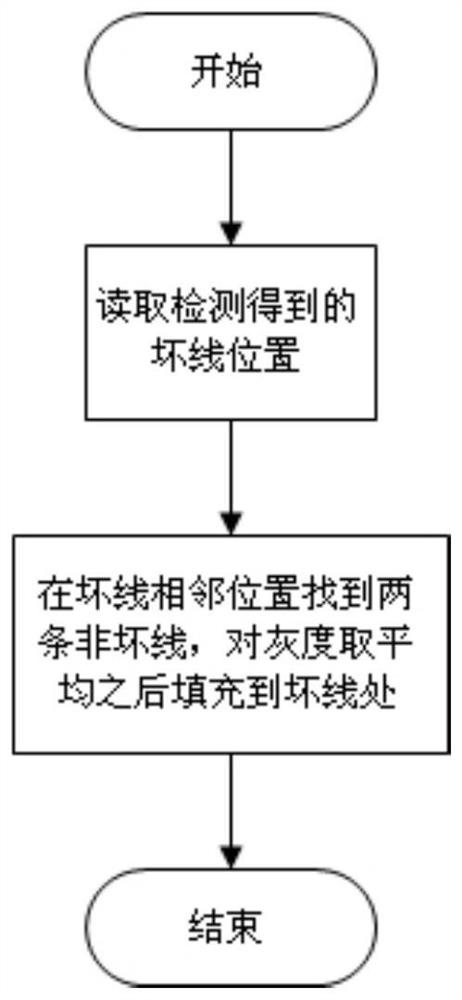

[0025] refer to figure 1 , is the broken line self-detection method of a kind of capacitive fingerprint collection system of the present invention, comprises the following steps:

[0026] Step 1, calculating the overall average grayscale of the entire fingerprint image collected and the row average grayscale of each row;

[0027] Step 2, if the overall average gray level of the entire fingerprint image is greater than threshold A, or less than threshold B, then the overall image effect of the judgment module does not meet the mass production standard, and it is judged as a defective prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com