Multifunctional Concrete Single Tensile Specimen Forming and Experimental Device

An experimental device and concrete technology, which is applied in the field of multi-functional test piece forming and experimental device, can solve the problems of eccentricity and incomplete contact, and achieve the effect of convenient use, convenient materials, and improvement of the forming quality of the test piece.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

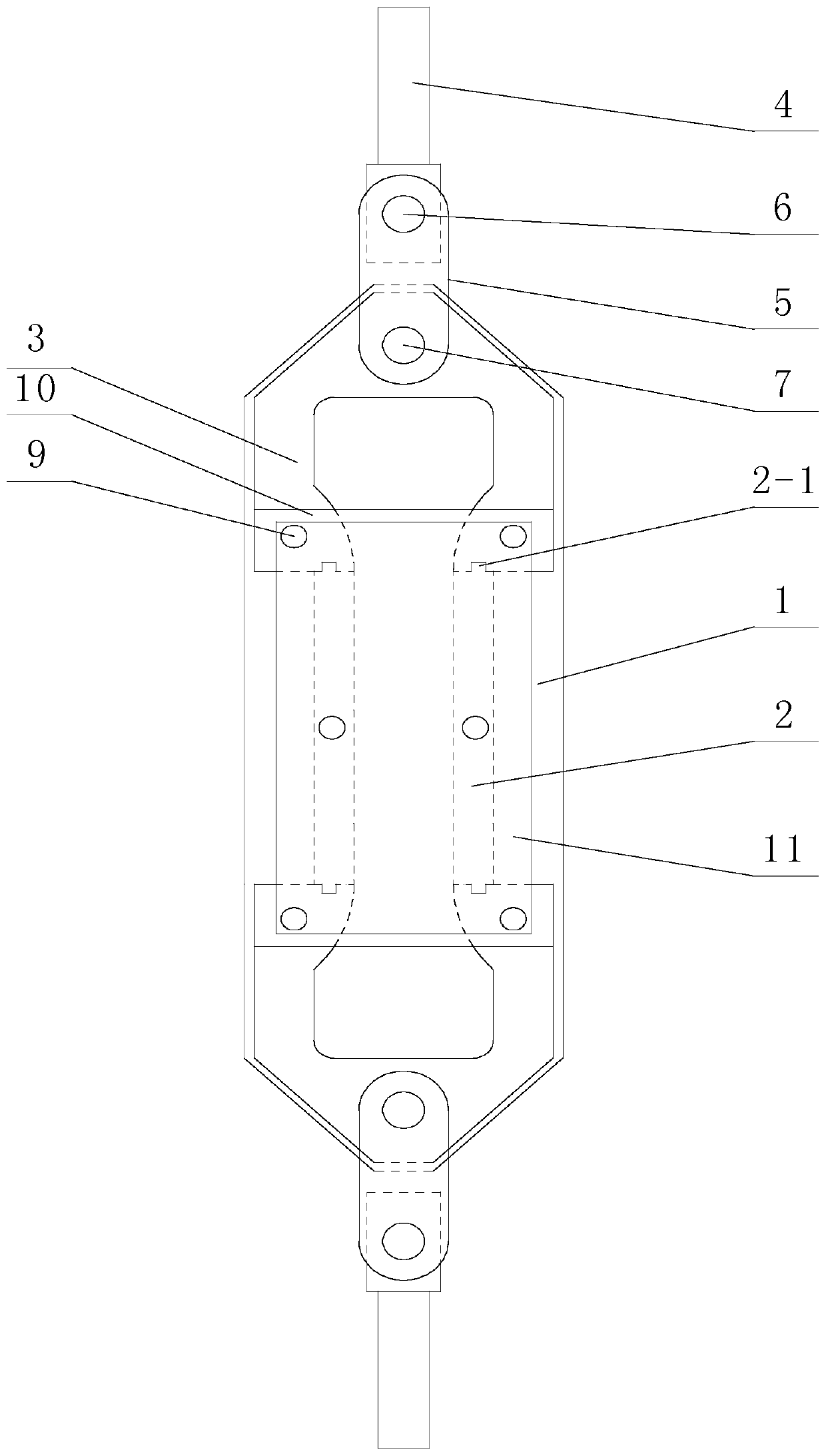

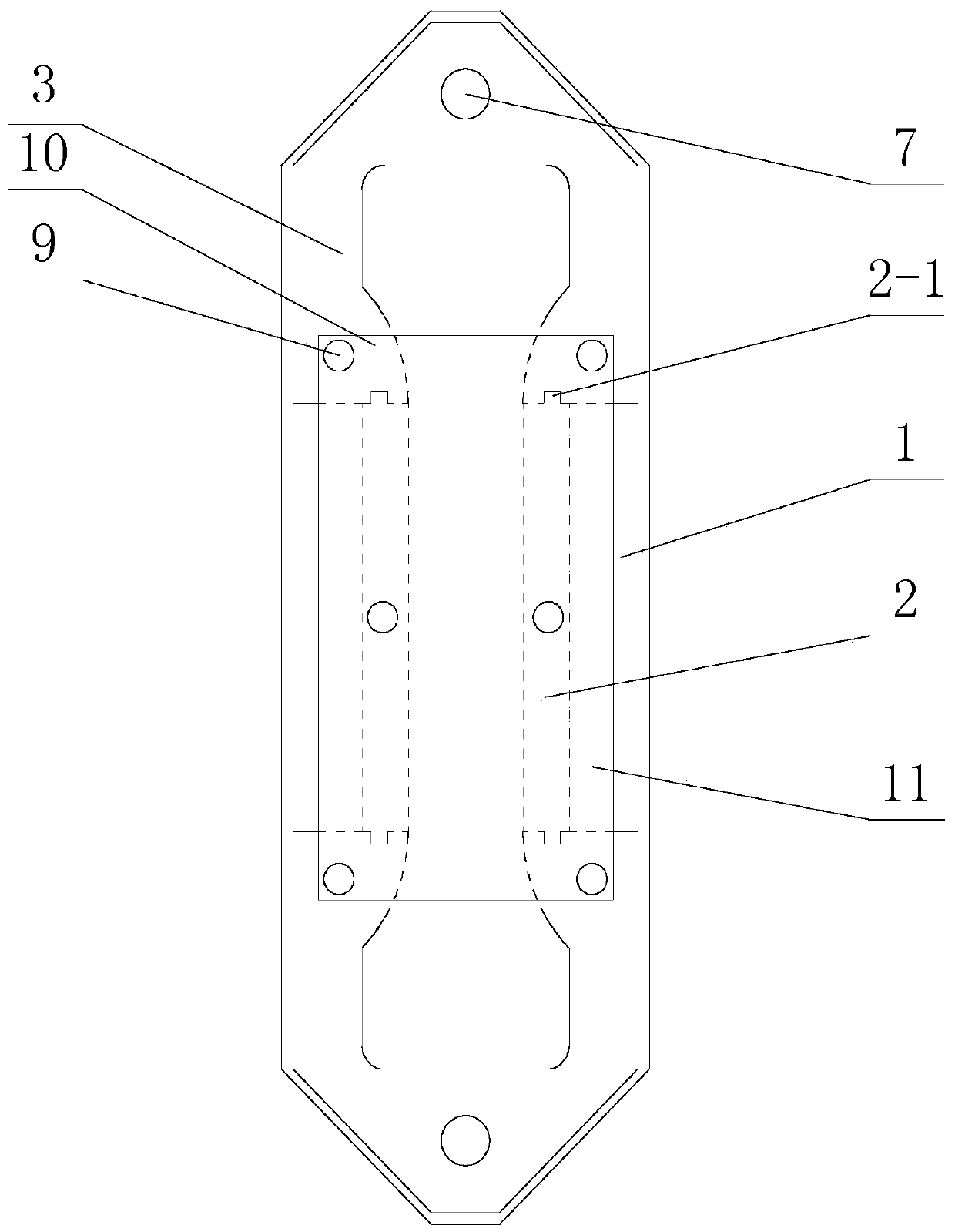

[0016] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, the multifunctional concrete single-tension test piece forming and experimental device described in this embodiment comprises mold bottom plate 1, two mold side plates 2, mold loam cake 11 and two mold fixture units, two mold side plates 2 The two ends of each mold side plate 2 are respectively connected to the two mold clamp units, and the mold upper cover 11 is connected to the mold side plate 2 and the mold clamp units. The mold side plate 2 is made of steel plates, which can be stacked in the thickness direction. The mold bottom plate 1 has a certain strength and rigidity, which is enough to ensure that the bottom surface of the concrete bottom is flat after prefabricated, without deformation. The mold upper cover 11 has certain strength and rigidity, and can be made of transparent materials, such as plexiglass, which is convenient for observing the molding quality of the test...

specific Embodiment approach 2

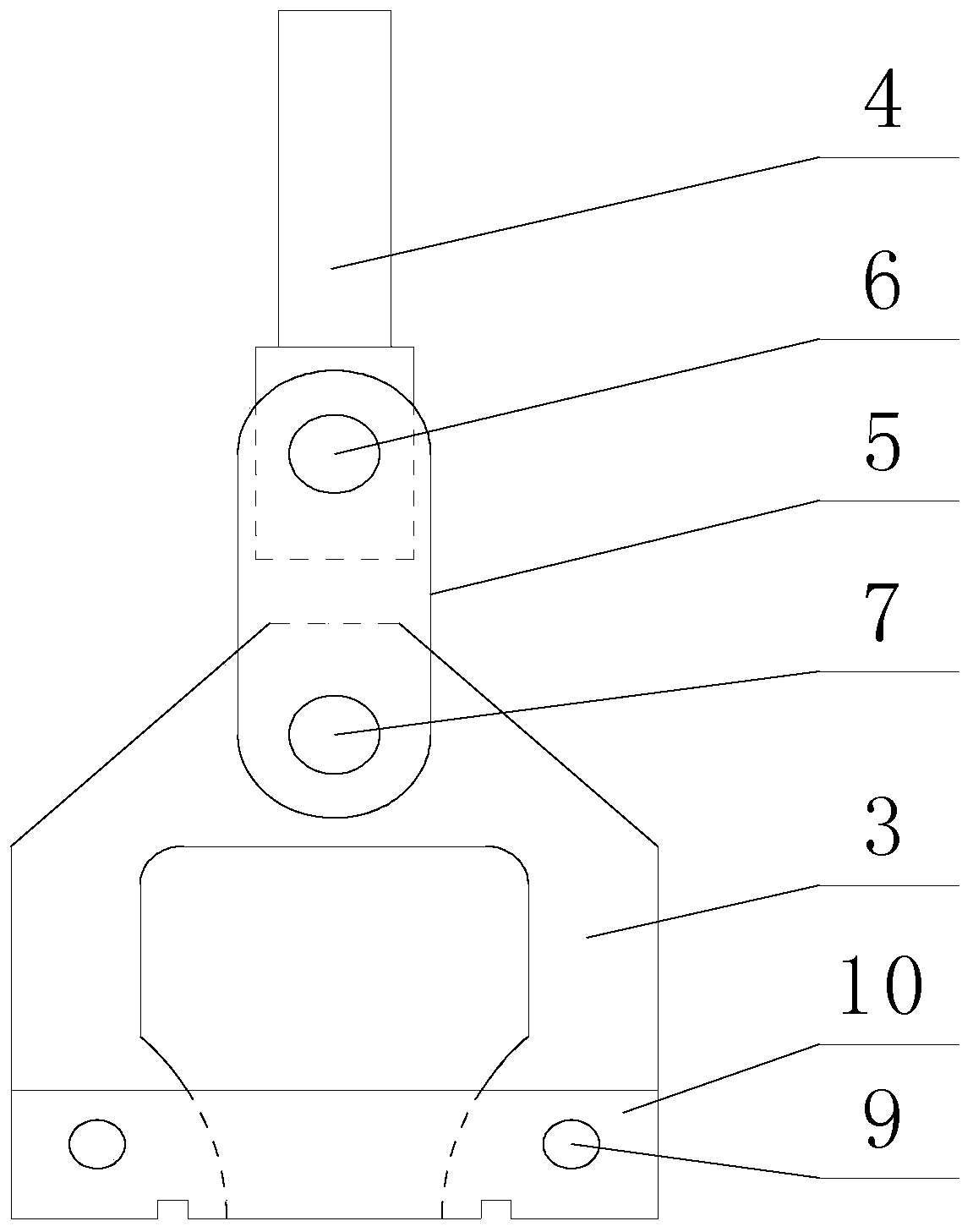

[0017] Specific implementation mode two: combination Figure 1 to Figure 3 Describe this embodiment, each described end plate fixture unit of multifunctional concrete single-tension test piece forming and experiment device described in this embodiment comprises fixture 3, tie rod 4 and two connecting plates 5, and two connecting plates 5 are arranged in parallel , one end of the pull rod 4 is connected to one end of the two connecting plates 5 , and the clamp 3 is connected to the other ends of the two connecting plates 5 .

[0018] The fixture 3 can be assembled from steel materials of different thicknesses with extremely high tensile strength according to the thickness of the tensile test pieces. The fixture should be symmetrically designed to ensure that the axis is consistent with the axis of the specimen. The contact surface between the fixture and the concrete should be set in a circular arc shape.

[0019] The tie rod 4 is strong enough to ensure no damage or fatigue ...

specific Embodiment approach 3

[0020] Specific implementation mode three: combination Figure 1 to Figure 3 Describe this embodiment, the multifunctional concrete single-tension test piece molding and experimental device described in this embodiment also includes a first pin 6 and a second pin 7, and one end of the pull rod 4 passes through the first pin 6 and one end of the two connecting plates 5 To connect, the clamp 3 is connected to the other ends of the two connecting plates 5 through the second pin 7 . Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com