Small vacuum three-target magnetron sputtering coating machine

A vacuum and magnetron technology, applied in the field of small vacuum magnetron three-target sputtering coating machine, to achieve the effect of protecting the safety of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

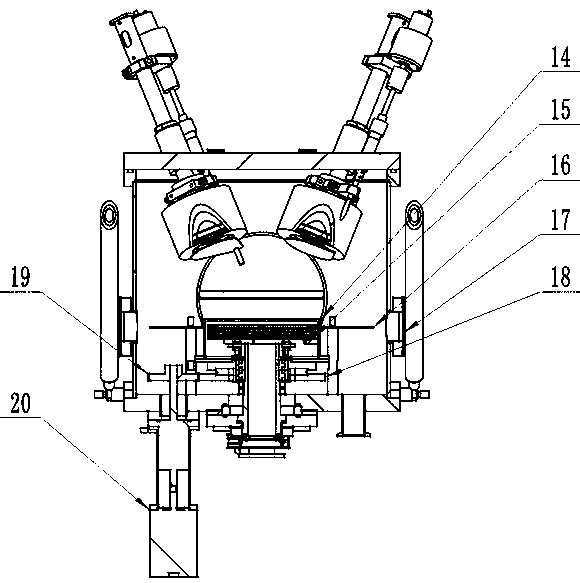

[0020] A small vacuum magnetron three-target sputtering coating machine, including a vacuum chamber 3, an upper cover 2 of the vacuum chamber, and three magnetron targets 1 uniformly distributed on the upper cover 2, in order to offset the gravity when the upper cover 2 is opened , the upper cover 2 is connected to two air pressure support rods 5, the front of the vacuum chamber 3 is provided with a glass observation window 4, the right side of the vacuum chamber 3 is provided with an auxiliary lighting interface 17, and on the back of the vacuum chamber 2, a throttle is provided. Valve 13, changing the angle of the throttle valve 13 changes the size of the airflow flowing into the molecular pump 11, which plays a role in adjusting the vacuum degree, and can also prevent a part of the sputtered material from entering the molecular pump 11, thereby prolonging the working life of the molecular pump 11. service life. The suction port of the molecular pump 11 is connected to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com