Preparation method of novel rubber vulcanizing activator

A rubber vulcanization and active agent technology, which is applied in the field of low-temperature preparation of new vulcanization active agents, can solve the problems of aquatic species threat, environmental pollution, waste of resources, etc., and achieve the effects of protecting the environment, improving mechanical properties, and reducing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

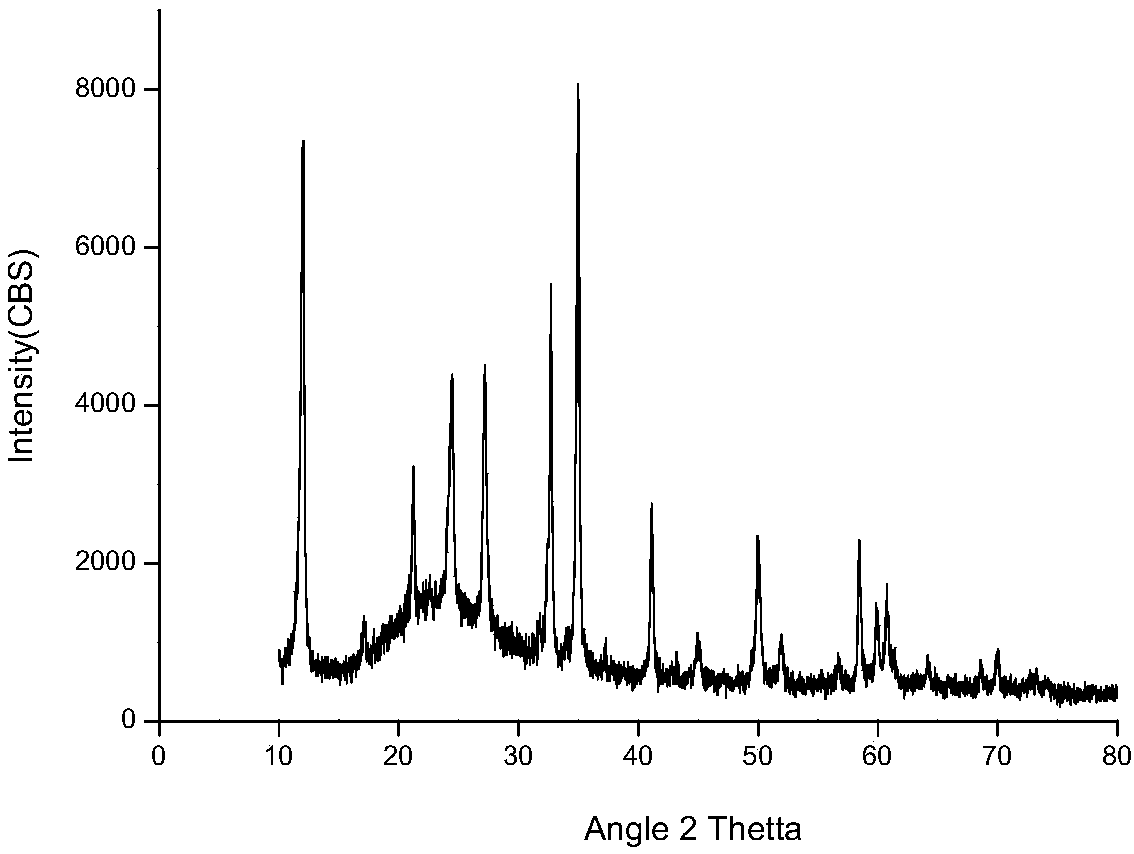

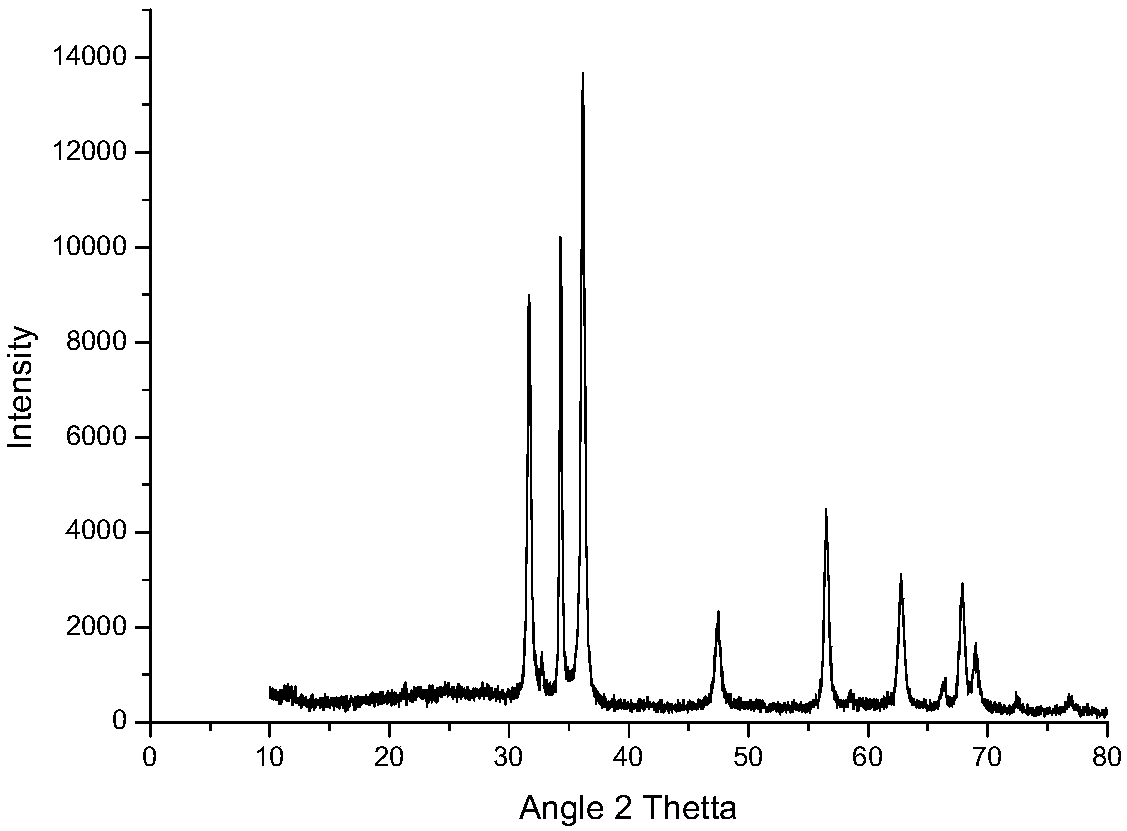

Image

Examples

preparation example Construction

[0025] A method for preparing a novel vulcanization activator based on silicon dioxide dispersion of the present invention comprises the following steps: 1) dispersing the ground silicon dioxide in ethanol, and adding zinc sulfate solution after continuously stirring the suspension for 1 hour at room temperature , and then warm up and add sodium hydroxide solution; 2) heat up and age, wash and filter, and dry into powder.

[0026] In order to obtain the optimal dispersion effect, the ratio of the new vulcanization activator to silicon dioxide was adjusted several times, and the best experimental parameters were obtained by comparing the experimental results.

Embodiment 1

[0029] 1) Preparation of silica suspension

[0030] Add 8 g of silicon dioxide ground for 1 h into 200 ml of absolute ethanol, ultrasonically disperse for 5 min, transfer to a flask at room temperature and continue magnetic stirring for 6 h at a stirring rate of 800 r / min.

[0031] 2) Preparation of new vulcanization activator

[0032] Add 28.7g of zinc sulfate heptahydrate to 10ml of deionized water, then add 90ml of absolute ethanol to dilute, ultrasonically dissolve, and 8.0g of sodium hydroxide to make a sodium hydroxide solution according to the above steps. First, add the zinc sulfate solution into the suspension in step 1), heat up and stir for 5 minutes, then quickly push the sodium hydroxide solution into the mixture with a medical syringe, and continue stirring for 30 minutes.

[0033] 3) Post-aging treatment

[0034] For the mixed solution in step 2), the temperature is raised to 100° C. for aging treatment, and at the same time, it is condensed and refluxed, and ...

Embodiment 2

[0039] 1) Preparation of silica suspension

[0040] Add 6 g of silicon dioxide ground for 1 h into 200 ml of absolute ethanol, ultrasonically disperse for 10 min, transfer to a 5 L flask and stir at room temperature for 30 min at a stirring rate of 2000 r / min.

[0041] 2) Preparation of new vulcanization activator

[0042] Add 14.5g of zinc sulfate heptahydrate to 10ml of deionized water, then add 90ml of absolute ethanol to dilute, ultrasonically dissolve, and 4.0g of sodium hydroxide to prepare a sodium hydroxide solution according to the above steps. First, zinc sulfate solution was added to the suspension in step 1), heated to 80° C. and stirred for 5 minutes, and then sodium hydroxide solution was injected into the mixture within 30 minutes using a medical syringe, and stirred for 30 minutes.

[0043] 3) Post-aging treatment

[0044] For the mixed liquid in step 2), the temperature is raised to 100° C. for aging treatment, and the stirring is continued for about 1 h. F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com