Formula of concrete for buildings

A technology for concrete and construction, applied in the field of preparation of concrete for construction, can solve problems such as poor corrosion resistance and easy occurrence of cracks, and achieve the effect of good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

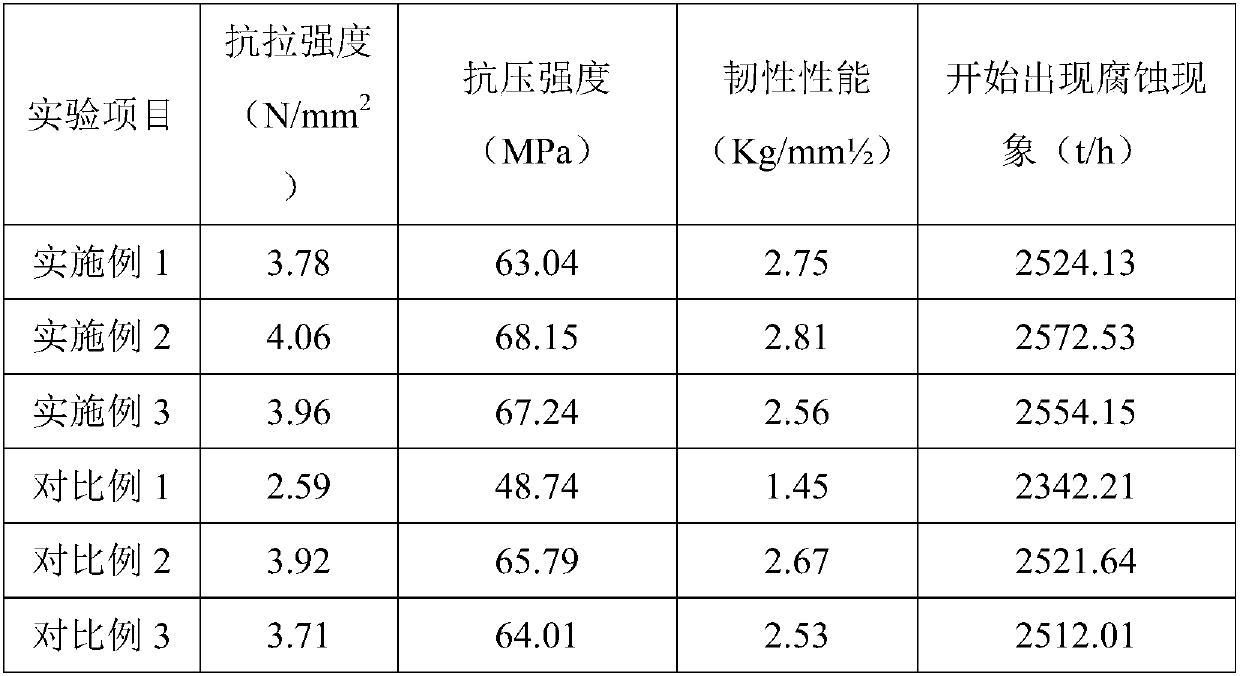

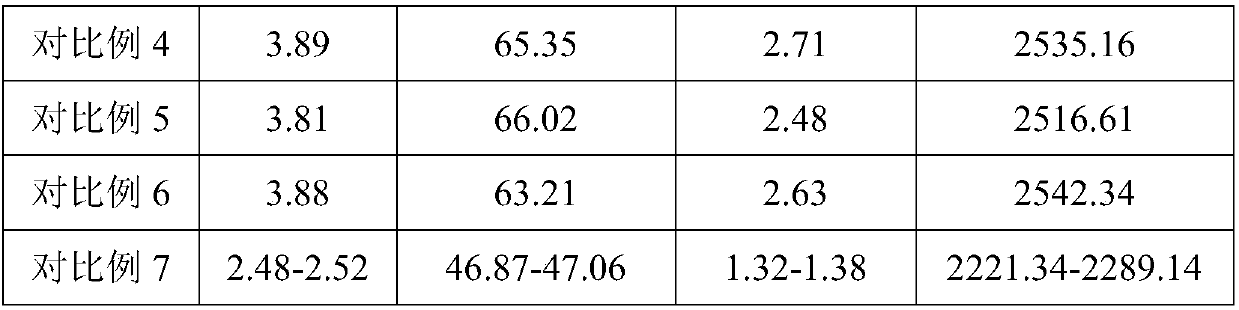

Examples

Embodiment 1

[0020] A kind of formula of concrete for construction, with the unit of weight part, comprising the following raw materials: 122 parts of cement, 25 parts of sand, 20 parts of stone, 250 parts of water, 16 parts of paper tendon, 18 parts of rice straw, 12 parts of hemp knife, polypropylene 8 parts of fiber, 4 parts of polyphenol novolac, 12 parts of polysulfone resin, poly[(2-oxiranyl)-1,2-cyclohexanediol] 2-ethyl-2-(hydroxymethyl)- 6 parts of 1,3-propanediol ether, 8 parts of SJ-101 resin, 3 parts of zinc trimerized acrylate;

[0021] The production technology of the formula of described building concrete, comprises the following steps:

[0022] S1, ingredients: firstly mix cement, sand, stone, water, paper rebar, rice straw, hemp knife, and polypropylene fiber according to the weight ratio to obtain a mixed homogeneous material;

[0023] S2. Modified material: Polysulfone resin, poly[(2-oxiranyl)-1,2-cyclohexanediol] 2-ethyl-2-(hydroxymethyl base)-1,3-propanediol ether, SJ...

Embodiment 2

[0026] A kind of formula of concrete for construction, with the unit of weight part, comprising the following raw materials: 140 parts of cement, 28 parts of sand, 25 parts of stone, 350 parts of water, 18 parts of paper tendon, 22 parts of rice straw, 15 parts of hemp knife, polypropylene 12 parts of fiber, 6 parts of polyphenol novolac, 18 parts of polysulfone resin, poly[(2-oxiranyl)-1,2-cyclohexanediol] 2-ethyl-2-(hydroxymethyl)- 8 parts of 1,3-propanediol ether, 10 parts of SJ-101 resin, 5 parts of zinc trimerized acrylate;

[0027] The production technology of the formula of described building concrete, comprises the following steps:

[0028] S1, ingredients: firstly mix cement, sand, stone, water, paper rebar, rice straw, hemp knife, and polypropylene fiber according to the weight ratio to obtain a mixed homogeneous material;

[0029] S2. Modified material: Polysulfone resin, poly[(2-oxiranyl)-1,2-cyclohexanediol] 2-ethyl-2-(hydroxymethyl base)-1,3-propanediol ether, ...

Embodiment 3

[0032] A kind of formula of concrete for construction, with the unit of weight part, comprising the following raw materials: 145 parts of cement, 29 parts of sand, 26 parts of stone, 400 parts of water, 20 parts of paper tendon, 25 parts of rice straw, 17 parts of hemp knife, polypropylene 15 parts of fiber, 8 parts of polyphenol novolac, 20 parts of polysulfone resin, poly[(2-oxiranyl)-1,2-cyclohexanediol] 2-ethyl-2-(hydroxymethyl)- 9 parts of 1,3-propanediol ether, 12 parts of SJ-101 resin, 6 parts of zinc trimerized acrylate;

[0033] The production technology of the formula of described building concrete, comprises the following steps:

[0034] S1, ingredients: firstly mix cement, sand, stone, water, paper rebar, rice straw, hemp knife, and polypropylene fiber according to the weight ratio to obtain a mixed homogeneous material;

[0035] S2. Modified material: Polysulfone resin, poly[(2-oxiranyl)-1,2-cyclohexanediol] 2-ethyl-2-(hydroxymethyl base)-1,3-propanediol ether, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com