Circular concentration method for treating dilute nitric acid produced by nitrotoluene waste sulfuric acid

A technology of nitrotoluene and dilute nitric acid, which is applied in the direction of nitric acid, nitrogen oxides/oxyacids, etc., can solve the problems of waste of nitro compounds, difficulty in realizing continuous separation of free nitro compounds, etc., achieve high degree of automation and improve use Value, the effect of increasing economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

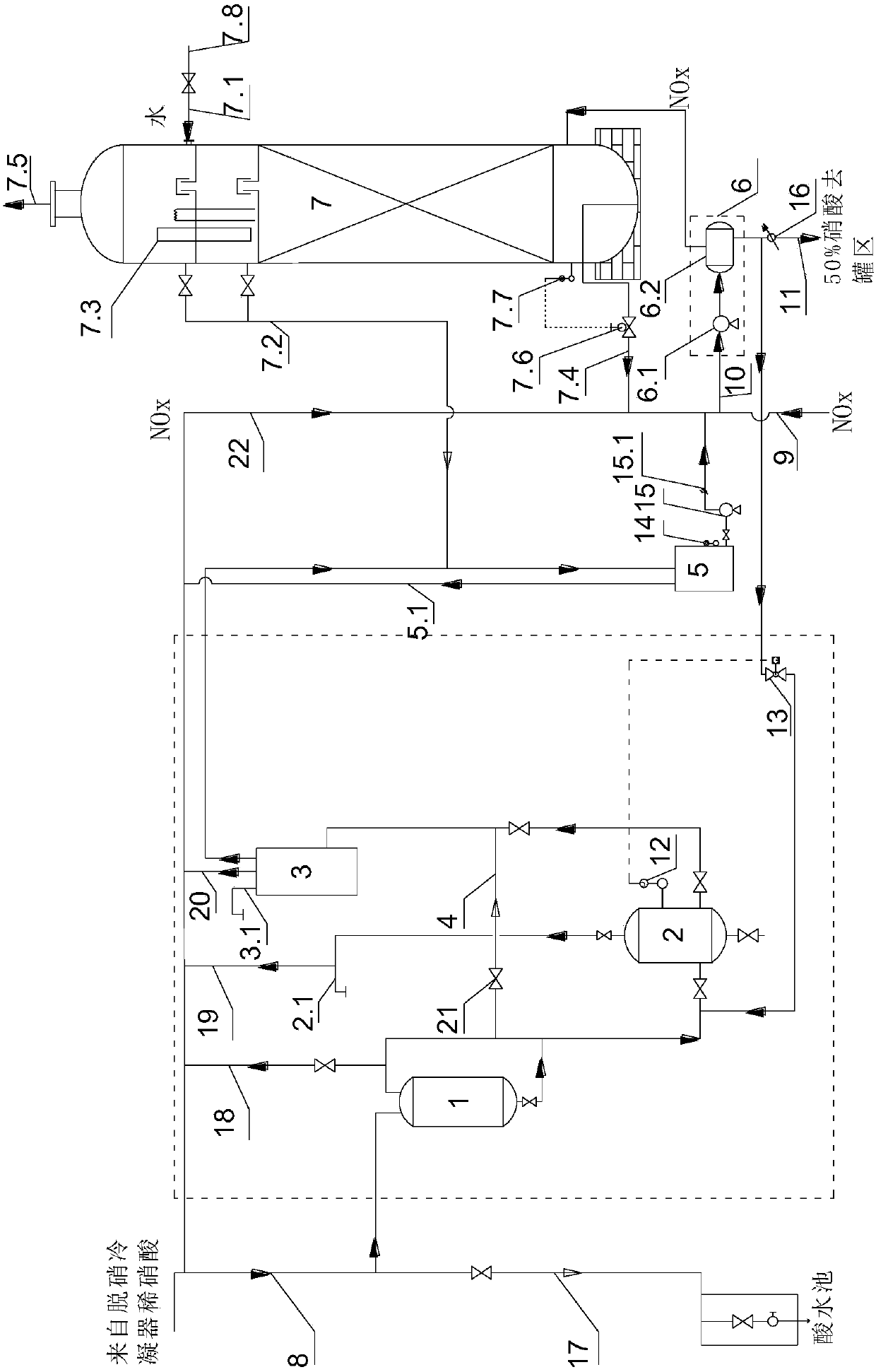

[0047] Such as figure 1 As shown, the device provided by the present invention for processing the cyclic enrichment method of dilute nitric acid produced by nitrotoluene waste sulfuric acid includes a cooler 1, an automatic separator 2, a manual separator 3, a handover tank 5, and a nitrogen oxide compressor unit. 6. The nitrogen oxide absorption tower 7 and the liquid and gas pipelines; the nitrogen oxide compressor unit 6 includes a nitrogen oxide compressor 6.1 and a separator 6.2 connected back and forth.

[0048] The cooler 1, the automatic separator 2, the manual separator 3, the handover tank 5, and the nitrogen oxide compressor unit 6 are connected in sequence through a liquid pipeline. The outlet pipeline of the nitrogen oxide compressor unit 6 is divided into two parallel paths, one way leads to the nitrogen oxide through a gas pipeline Abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com