Packaging device for storing mini-pill medicine and use method of packaging device

A technology of micropills and drugs, which is applied in packaging, dispensing devices, transportation and packaging, etc., can solve the problems of no micropill packaging device, large packaging space, time-consuming and inconvenient operation, and solve the problem of cumbersome dosage operation, Effects of reducing operational difficulty and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1 Children's micropill administration: seven tenths dose

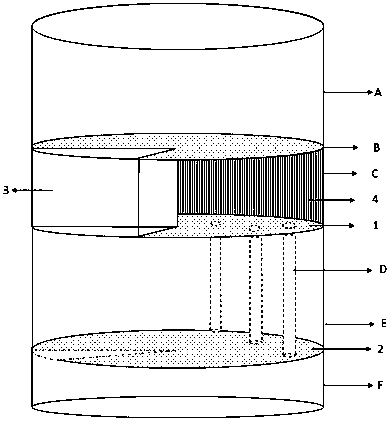

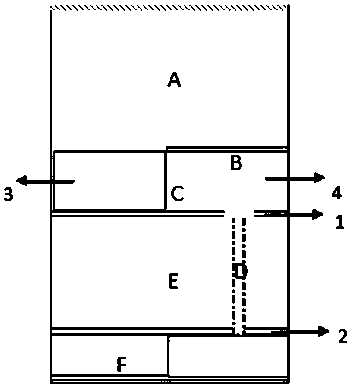

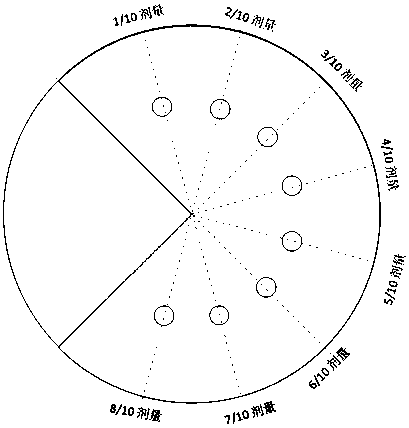

[0052] Put the pellets of the production batch 2017-XXXX into the pill storage room A, then install the control board B, the initial dose area C, the second dose tube D, the second dose area E, and the administration area F in order, and rotate Adjust the control board B so that the sieve hole is vertically corresponding to the temporary storage area of the initial dosage area C, and the pellets in the pill storage room A will flow into the initial dosage area C through the sieve hole due to gravity; the pellets in the temporary storage area will be accumulated until When the volume of the temporary storage area is 75%, slowly rotate the control panel B to block the openings of the pill storage chamber A and the initial dose area C, and then slowly rotate clockwise from the initial dose area C to the second dose area E area At the 7 / 10 dose, the pellets in the initial dose area C will fill up the su...

Embodiment 2

[0053] Example 2 Normal administration for adults

[0054] Put the pellets of the production batch 2017-XXXX into the pill storage room A, and then install the control panel B, the initial dose area C, the second dose tube D, the second dose area E, and the administration area F in sequence. When the pellets in the pill storage chamber A flow into the initial dose area C, slowly rotate the control panel B to block the openings of the pill storage chamber A and the initial dose area C, and then slowly rotate the initial dose area C clockwise to At the 5 / 10 dose of the sub-dose area E area, the pellets in the initial dose area C will fill up the sub-dose tube D, but at this time, it is necessary to ensure that the pill receiving area of the administration area F is in an inactive area. Then slowly rotate the dosing area F counterclockwise and unload it. During the rotation, 1 / 10 to 5 / 10 of the pellets filled in the tube will fall into the dosing area F due to gravity. Repeat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com