Selective cluster-by-cluster fracturing technology for horizontal wells in shale gas reservoirs

A technology for shale gas reservoirs and horizontal wells, which is applied to wellbore/well components, production fluids, and earth-moving drilling, etc. It can solve the problems of affecting the number of fracturing stages, difficult to achieve targeted stimulation, etc., and achieve flexible perforation positions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A selective cluster-by-cluster fracturing process for horizontal wells in shale gas reservoirs, including: dividing the horizontal well section into several clusters, performing 1 to 4 clusters of sandblasting and perforating each time through coiled tubing, and then performing main fracturing, cluster-by-cluster multiple times The fracturing of horizontal wells was completed; in the later stage of the main fracturing, sand plugs were used to seal the fracture openings and the clusters were transferred. In the first cluster, coiled tubing and casing annulus were used for main fracturing or bare casing fracturing. 4 clusters use coiled tubing to lift out of the wellhead for bare casing main fracturing, and the entire wellbore maintains a full diameter during the fracturing process.

[0034] Described method specifically comprises the steps:

[0035] (1) According to the construction requirements, ground preparation work is carried out, the coiled tubing is used to wash t...

Embodiment 2

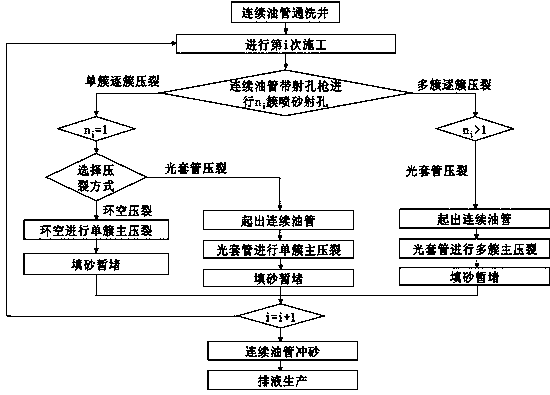

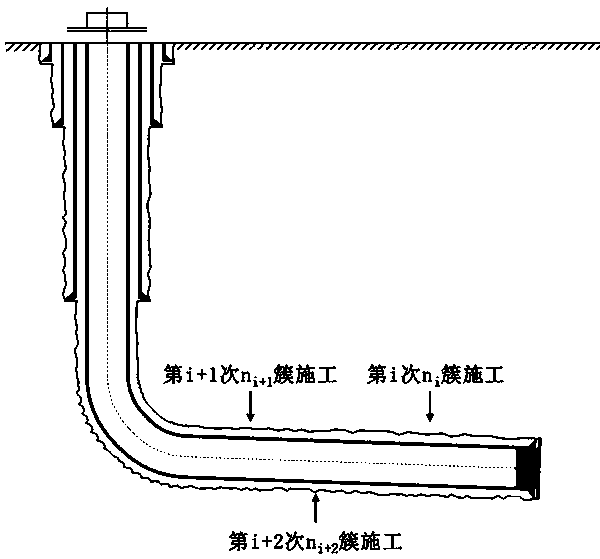

[0049] Process flow of the present invention such as figure 1 as shown, figure 1 Among them, i=1, 2... is the number of horizontal well section stimulation; n i =1, 2... is the number of construction clusters for the i-th transformation. The process of the present invention will be further described below.

[0050] Firstly, ground preparation is carried out according to the construction requirements, the coiled tubing is used to clean the well, the highest safe pump pressure is set (the safe pump pressure is generally 10~20MPa higher than the construction pressure), and the main fracturing preparation is carried out.

[0051] If the main fracturing is single-cluster fracturing, the coiled tubing with flushing head and sandblasting perforating tool is lowered, the depth is adjusted, and the first fracturing cluster is performed at the designated position of the horizontal well through the coiled tubing combined with sandblasting and perforating tools. Perform sandblasting an...

Embodiment 3

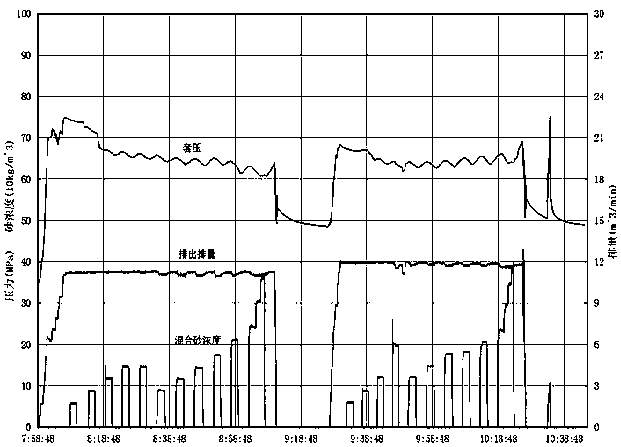

[0056] Well YSN-1 was drilled in the Silurian Longmaxi Formation, and was completed with 139.7mm reservoir casing. The drilling depth of the well is 4210m, the vertical depth is 2539.72m, the maximum well deviation is 84.25°, the entry point is at 2510m, the exit point is at 4210m, and the horizontal section is 1700m long. Well YSN-1 encountered reservoirs with good physical properties, with an average effective porosity of 3.8%, an average TOC of 3.7%, and an average total gas content of 4.3m 3 / t, the reservoir brittleness index in the horizontal section is medium. The triaxial stress of the reservoir is characterized by strike-slip faults, the difference between the maximum and minimum horizontal principal stress is large (greater than 15 MPa), the reservoir is heterogeneous, natural fractures are less developed, and the east side of the wellbore is close to the fault. The well design applies the present invention to 72 clusters of fracturing operations.

[0057] (1) The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com