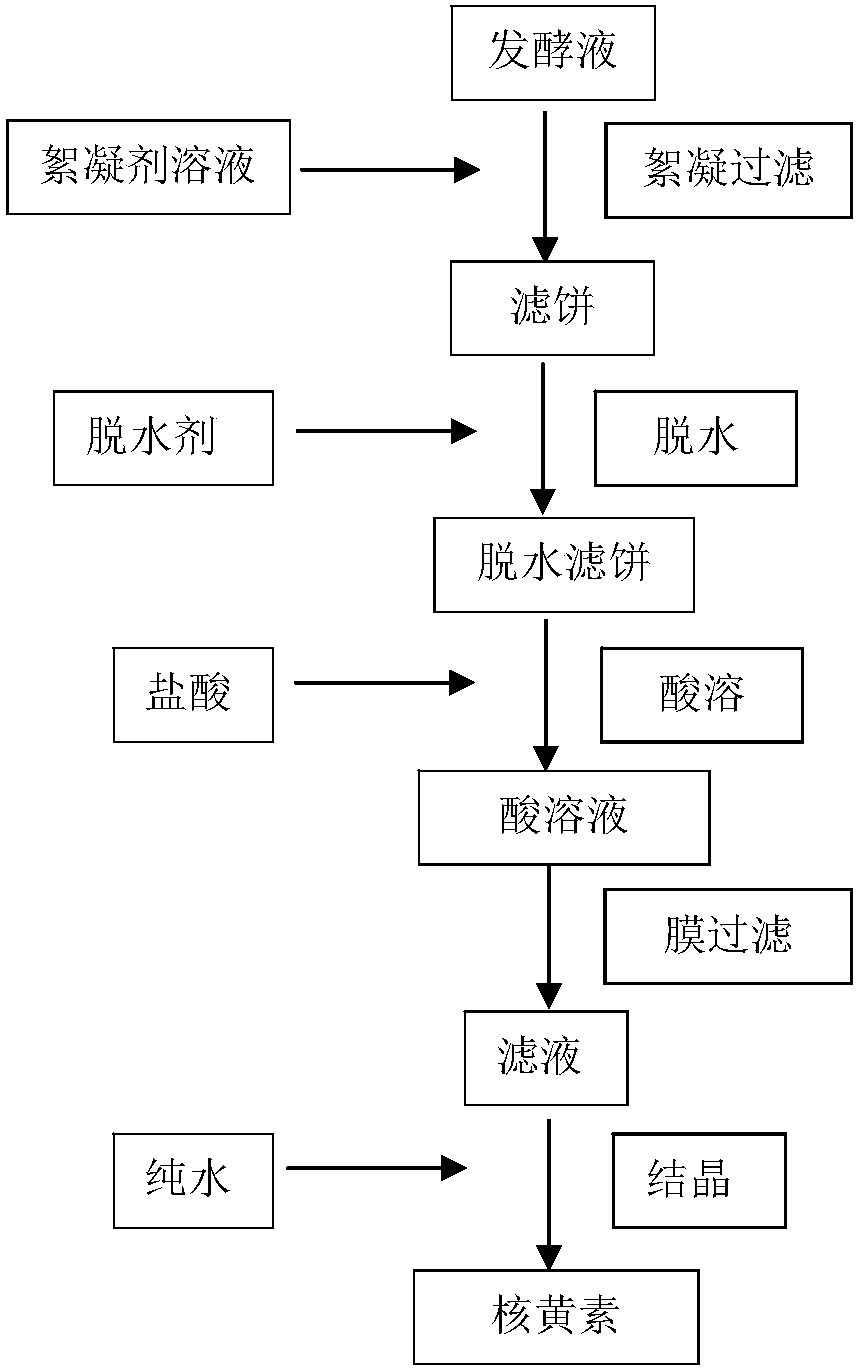

Method for extracting riboflavin from riboflavin fermentation liquor

A technology of riboflavin and fermented liquid, applied in the direction of organic chemistry, can solve problems such as loss, achieve the effects of reducing impurities, increasing extraction yield and product content, and saving filtration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] After mixing 3 parts of diatomite and 97 parts of chitosan evenly, put them into pure water and stir to dissolve, the stirring speed is controlled at 15r / min, and stir for 3h. The agent is ready for use.

[0051] Take 10L of riboflavin fermentation broth (titer 23542mg / l) and heat it to 78°C, keep it warm for 30min, after the heating is completed, cool down to 30°C in a water bath. After cooling down, add 300ml of the above-mentioned flocculant into the fermentation broth while stirring, and the stirring speed is controlled at 5r / min. Then, the flocculated liquid was filtered using a Buchner funnel, and the total filtration time was 30 minutes to obtain 1420 g of filter cake with a yield of 99.3%.

[0052] Add the filtered filter cake into a beaker, add 2500ml of ethanol to the filter cake, stir for 30min, and filter after the stirring is completed. The total filtration time is 10min, and 1200g of filter cake is obtained by filtration with a yield of 99.8%.

[0053] I...

Embodiment 2

[0057] After mixing 5 parts of a mixture of diatomite and activated carbon (wherein the weight of diatomite and activated carbon is 50%) and 95 parts of polyacrylamide evenly, put it into pure water and stir to dissolve, and the stirring speed is controlled at 20r / min. After stirring for 2.5 hours, after the stirring is completed, a flocculant with a mass concentration of polyacrylamide of 0.1% is prepared for use.

[0058] Take 10L riboflavin fermentation liquid (titer 23542mg / l) and heat it to 75°C, keep it warm for 60min, after the heating is completed, cool down to 20°C in a water bath. After cooling down, add 500ml of the above-mentioned flocculant into the fermentation broth while stirring, and the stirring speed is controlled at 10r / min. Then, the flocculated flocculant was filtered using a Buchner funnel, and the total filtration time was 25 minutes to obtain 1500 g of filter cake with a yield of 99.5%.

[0059] Add the filtered filter cake into a beaker, add 3000ml o...

Embodiment 3

[0064] The mixture of 4 parts of perlite and activated carbon (wherein perlite accounts for 40% by weight, and activated carbon accounts for 60% by weight) is mixed with 96 parts of polyalumina evenly, and then put into pure water and stirred to dissolve, the stirring speed is controlled at 20r / min, stirred for 2 hours, and after the stirring was completed, a flocculant with a mass concentration of polymerized alumina of 0.3% was prepared for use.

[0065] Take 10L of riboflavin fermentation broth (titer 23542mg / l) and heat it to 95°C, keep it warm for 30min, after the heating is completed, cool down to 35°C in a water bath. After cooling down, add 700ml of the above-mentioned flocculant into the fermentation broth while stirring, and the stirring speed is controlled at 5r / min. Then, the flocculated flocculant was filtered using a Buchner funnel, and the total filtration time was 32 minutes to obtain 1385 g of filter cake with a yield of 99.3%.

[0066] Add the filtered filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com