Method for preparing molasses-base hydrothermal carbon

A technology of hydrothermal charcoal and molasses, applied in the direction of carbon preparation/purification, etc., can solve the problems of poor electrical performance of hydrothermal charcoal, corrosion of reaction equipment, environmental pollution of molasses, etc., to promote the separation of charcoal layers and improve the transfer of electrons The effect of ability, reaction process and ease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

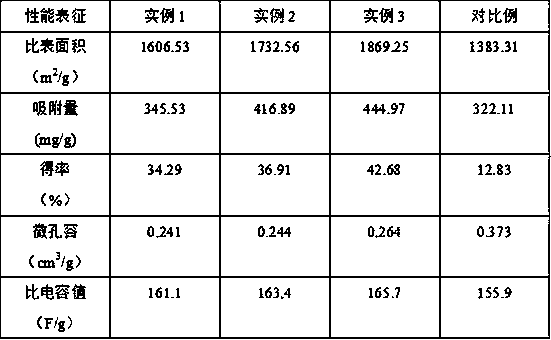

example 1

[0023] Take 10g of molasses, add 50mL of deionized water, stir at 300r / min for 20min, then add 1g of L-cysteine, 2g of ammonia water with a mass fraction of 20%, 2g of ethyl orthosilicate, and continue stirring at 30°C for 4h , to obtain a reaction solution, put the reaction solution into a hydrothermal reaction kettle, heat to 160°C for 12h, then heat to 200°C for 20h, cool to room temperature, take out and filter to obtain filter residue, alternately wash with deionized water and absolute ethanol Until the washing solution is neutral, place it in a drying oven and dry at 80°C for 3 hours to obtain a carbon material precursor. Take 1g of the carbon material precursor, soak it in 100g of a 10% potassium carbonate solution by mass fraction, and dry it at 70°C Stir at 300r / min for 4h, filter the filter cake, wash with deionized water until the washing liquid is neutral, place in a drying oven, dry at 80°C for 3h, and then put it into a muffle furnace, under a nitrogen atmosphere ...

example 2

[0025] Take 15g of molasses, add 75mL of deionized water, stir at 350r / min for 25min, then add 1g of L-cysteine, 3g of ammonia water with a mass fraction of 20%, 3g of ethyl orthosilicate, and continue stirring at 35°C for 5h , to obtain a reaction solution, put the reaction solution into a hydrothermal reaction kettle, heat to 170°C for 14h, then heat to 220°C for 25h, cool to room temperature, take out and filter to obtain filter residue, alternately wash with deionized water and absolute ethanol Until the washing solution is neutral, place it in a drying oven and dry at 85°C for 4 hours to obtain a carbon material precursor. Take 1g of the carbon material precursor, soak it in 150g of a 10% potassium carbonate solution, and heat it at 75°C Stir at 350r / min for 5h, filter the filter cake, wash with deionized water until the washing liquid is neutral, place in a drying oven, dry at 85°C for 4h, and then put it into a muffle furnace, under nitrogen atmosphere , heated to 550°C...

example 3

[0027] Take 20g of molasses, add 100mL of deionized water, stir at 400r / min for 30min, then add 2g of L-cysteine, 4g of 20% ammonia by mass fraction, 4g of ethyl orthosilicate, and continue stirring at 40°C for 6h , to obtain a reaction solution, put the reaction solution into a hydrothermal reaction kettle, heat to 180°C for 16h, then heat to 240°C for 30h, cool to room temperature, take out and filter to obtain filter residue, alternately wash with deionized water and absolute ethanol Until the washing solution is neutral, place it in a drying oven and dry at 90°C for 5 hours to obtain a carbon material precursor. Take 2g of the carbon material precursor, soak it in 200g of a 10% potassium carbonate solution, and heat it at 80°C Stir at 400r / min for 6h, filter the filter cake, wash with deionized water until the washing liquid is neutral, put it in a drying oven, dry at 90°C for 5h, then put it into a muffle furnace, under a nitrogen atmosphere , heated to 600°C for activati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com