Bar sealing structure of pulverization device

A technology of sealing structure and pulverizing equipment, applied in the field of 3D printing, can solve the problems of complex operation, difficult to grasp the size of the force, and difficult to automate control, and achieve the effect of simple operation and easy automatic control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

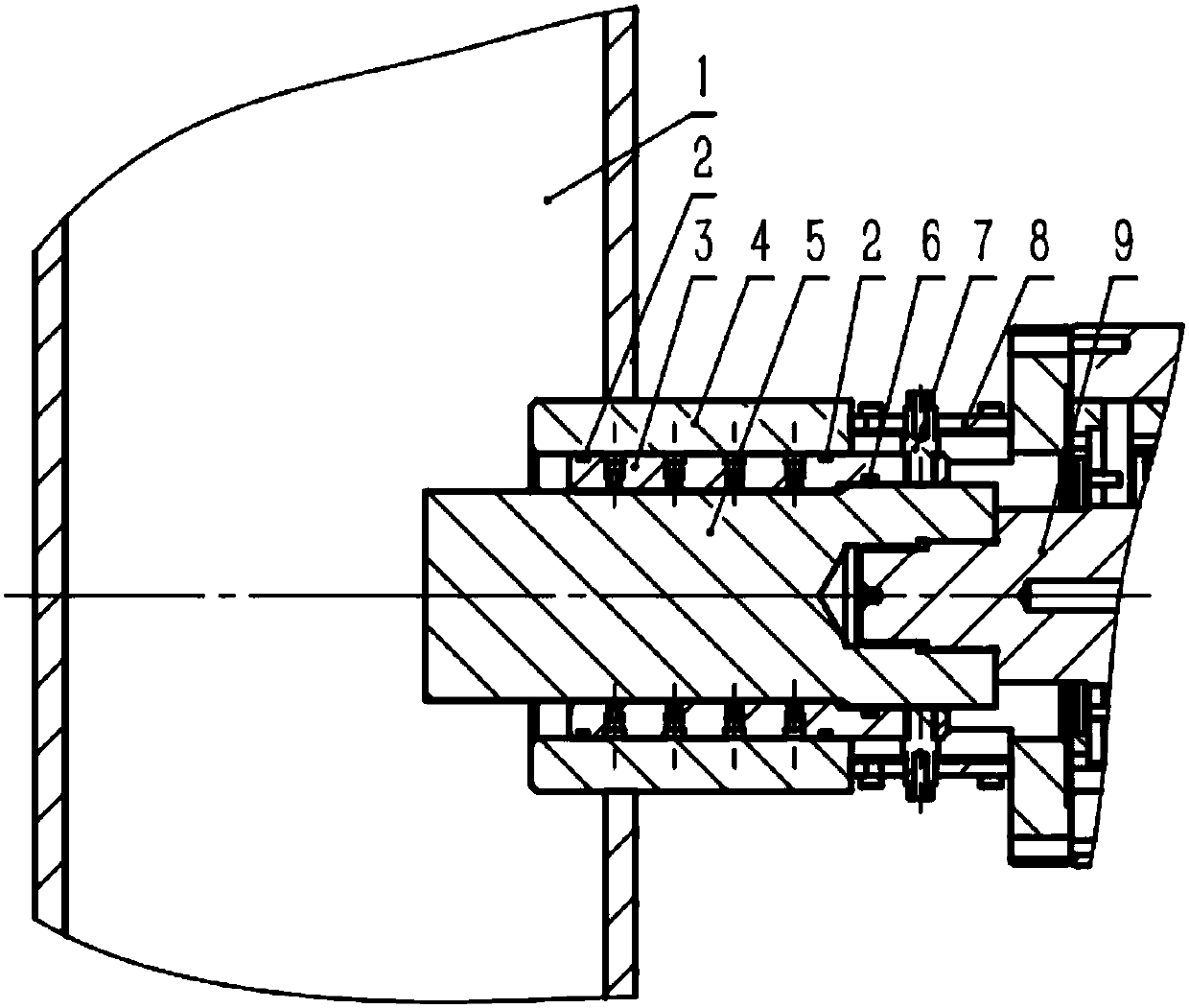

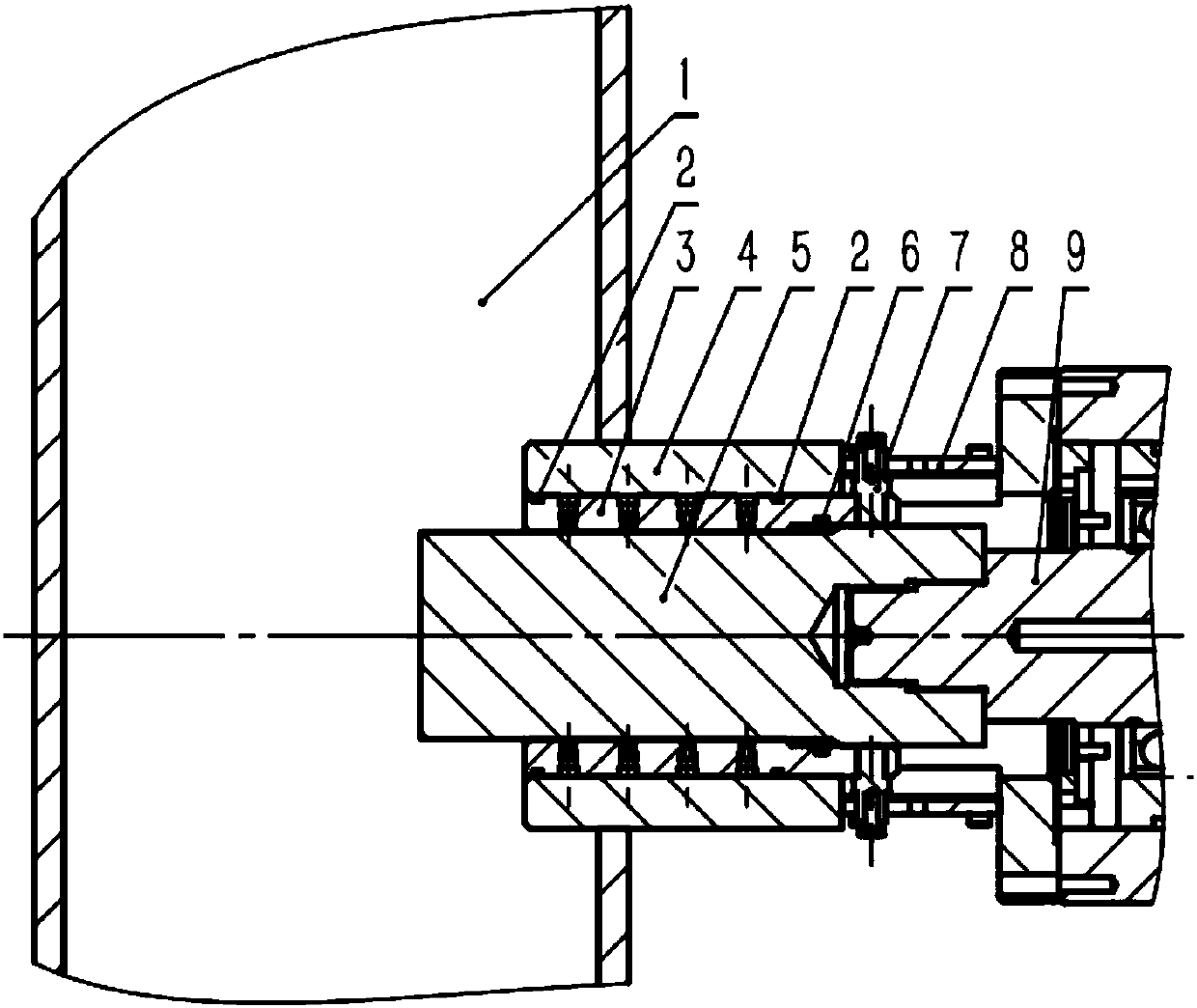

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

[0025] see figure 1 and figure 2 : The rod sealing structure of the powder making equipment of the present invention includes a base 4 for fixing the sealing part, an inner sleeve 3 that is installed on the inner diameter of the base 4 and can move axially, and is used to stir the inner sleeve 3 to move The lever 7, the limit plate 8 that limits the moving position of the inner sleeve 3; the inner sleeve 3 is inserted with a bar connecting sleeve 5, and there is a gap between the bar connecting sleeve 5 and the inner sleeve 3, and the inner sleeve 3 and the base 4 An inner sleeve and an outer sealing ring 2 are arranged therebetween. The limiting plate 8 is arranged at the right end of the inner sleeve 3, and the limiting plate 8 is installed in cooperation with the driving lever 7. A chute for axial sliding of the driving rod 7 is provided on the limiting plate 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com