A dynamic magnetic particle combined membrane extraction device and extraction method

The technology of extraction device and magnetic particle is applied in the field of dynamic magnetic particle combined membrane extraction device, which can solve the problem of uneven distribution of fluid, and achieve the effects of uniform distribution of fluid, improved extraction efficiency and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

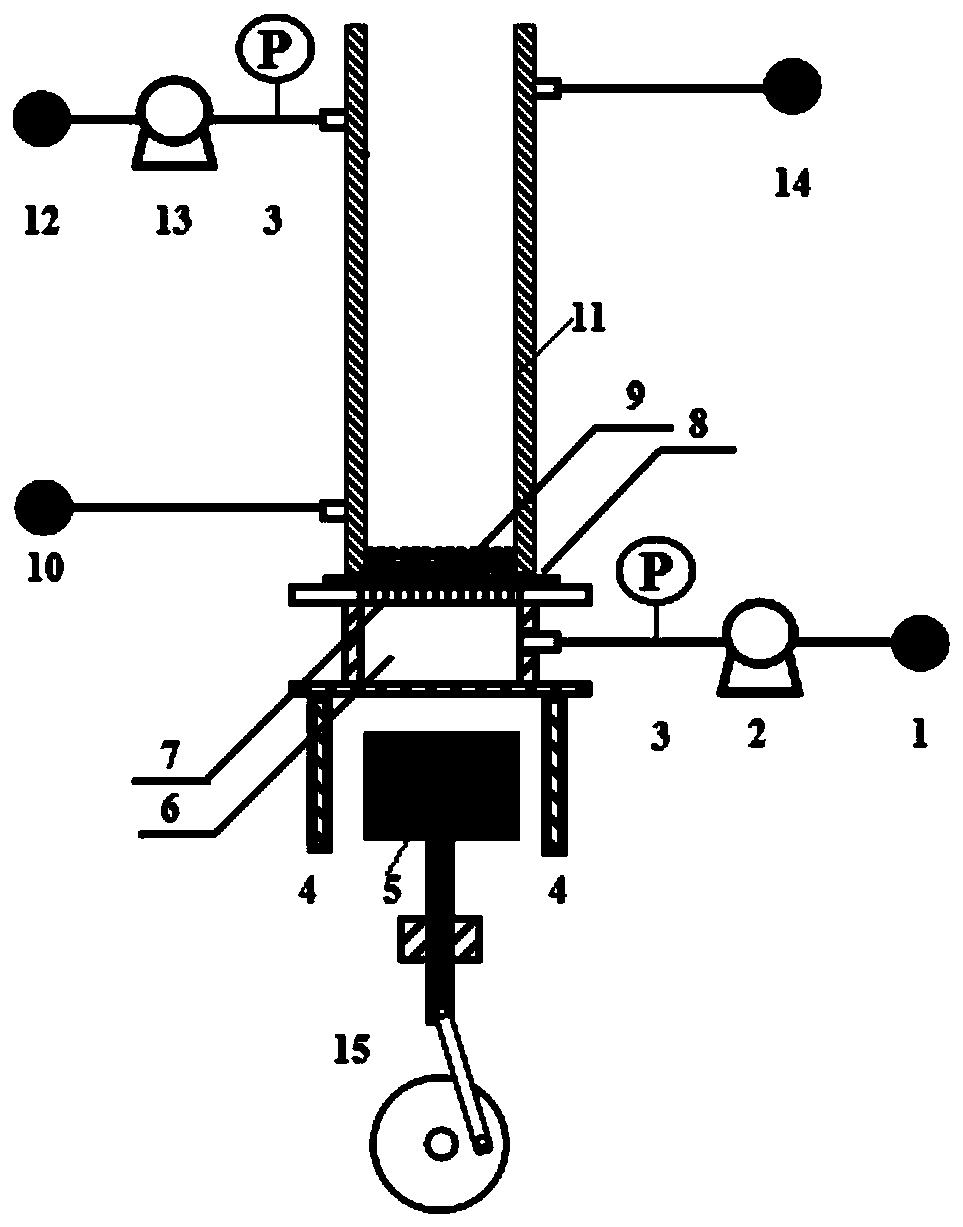

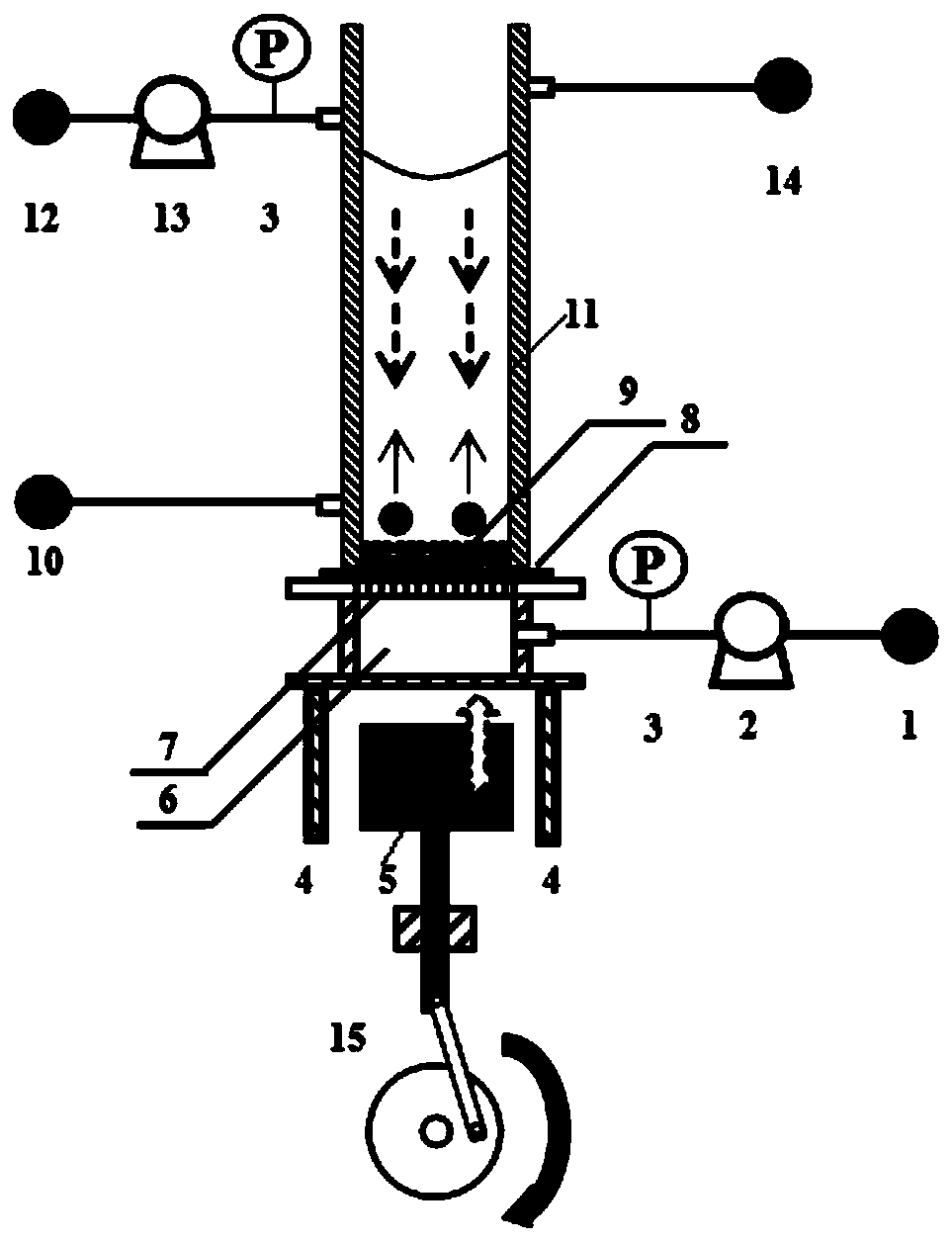

Method used

Image

Examples

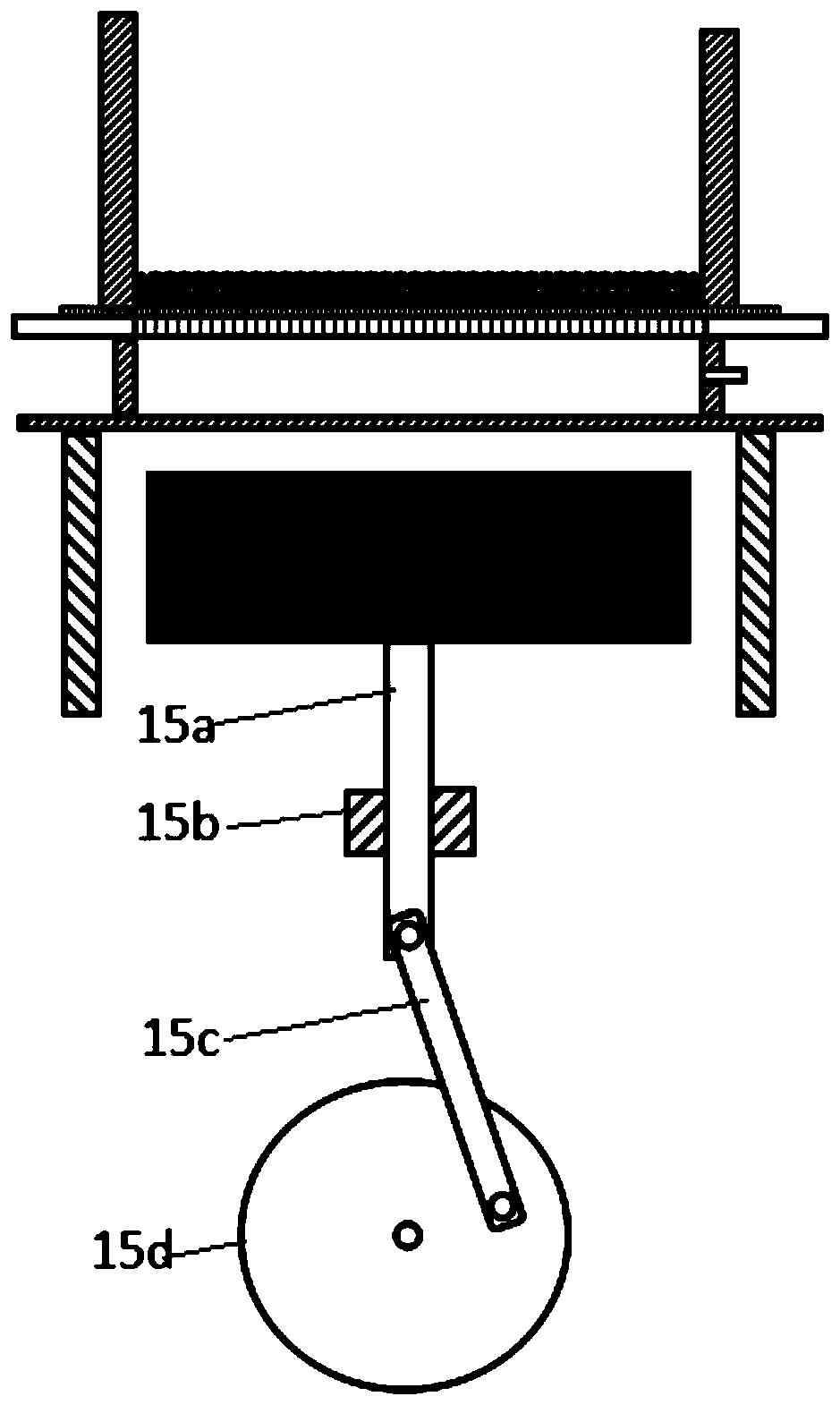

Embodiment 1

[0064] In this example, the volume ratio of TBP extractant and sulfonated kerosene diluent is 2:8, and they are mixed to form an organic extract phase. The feed liquid phase is an aqueous solution containing propionic acid, the concentration of propionic acid is 0.405mol / L, and the pH value of the solution is 2.63. Among them, in the dynamic magnetic particle combination film, the magnetic particles used are Fe-containing 3 0 4 Magnetic particles, the particle size of the magnetic particle 9 is about 500 μm, and the thickness of the magnetic particles is about 3 mm; steel wire mesh is used as a thin layer bedding, and its aperture is 10 μm; the sieve plate is plexiglass, covered with pores with an aperture of 5 mm , the porosity is 24%, and the effective area of thin layer bedding is 20.25cm 2 The amplitude of the magnet transmission device is 10cm, and the rotation frequency is 20 rpm. The magnets used are cylindrical magnets, the S level is upward, and the magnetic parti...

Embodiment 2

[0066] In this example, the volume ratio of TBP extractant and sulfonated kerosene diluent is 3:7, and they are mixed to form an organic extract phase. The feed liquid phase is an aqueous solution containing propionic acid, the concentration of propionic acid is 0.405mol / L, and the pH value of the solution is 2.63. Among them, in the dynamic magnetic particle combination film, the magnetic particles used are Fe-containing 3 0 4 Magnetic particles, the particle size of the magnetic particle 9 is about 500 μm, and the thickness of the magnetic particles is about 3 mm; steel wire mesh is used as a thin layer bedding, and its aperture is 10 μm; the sieve plate is plexiglass, covered with pores with an aperture of 5 mm , the porosity is 24%, and the effective area of thin layer bedding is 20.25cm 2 The amplitude of the magnet transmission device is 12cm, and the rotation frequency is 40 rpm. The magnets used are cylindrical magnets, the S level is upward, and the magnetic parti...

Embodiment 3

[0068] In this example, the volume ratio of TBP extractant and sulfonated kerosene diluent is 4:6, and they are mixed to form an organic extract phase. The feed liquid phase is an aqueous solution containing propionic acid, the concentration of propionic acid is 0.405mol / L, and the pH value of the solution is 2.63. Among them, in the dynamic magnetic particle combination film, the magnetic particles used are Fe-containing 3 0 4 Magnetic particles, the particle size of the magnetic particle 9 is about 500 μm, and the thickness of the magnetic particles is about 3 mm; steel wire mesh is used as a thin layer bedding, and its aperture is 10 μm; the sieve plate is plexiglass, covered with pores with an aperture of 5 mm , the porosity is 24%, and the effective area of thin layer bedding is 20.25cm 2 The amplitude of the magnet transmission device is 8cm, and the rotation frequency is 50 rpm. The magnets used are cylindrical magnets, the S level is upward, and the magnetic partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com