Method for building graded broken stone shear resistance number value prediction models

A technology of grading crushed stone and pre-estimating model, which is used in electrical digital data processing, special data processing applications, and testing the strength of materials by applying a stable shear force. The evaluation of layer shear resistance is single and other problems, to achieve the effect of rapid judgment, improve efficiency, and reduce the capacity of the original disk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

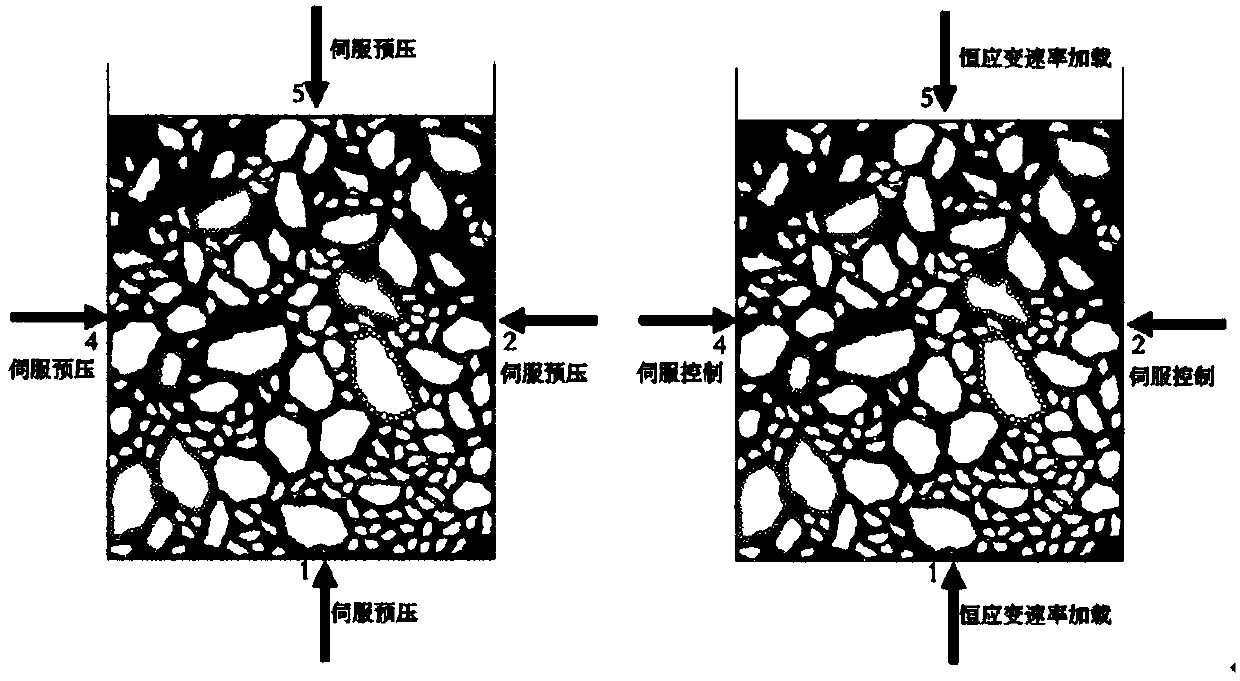

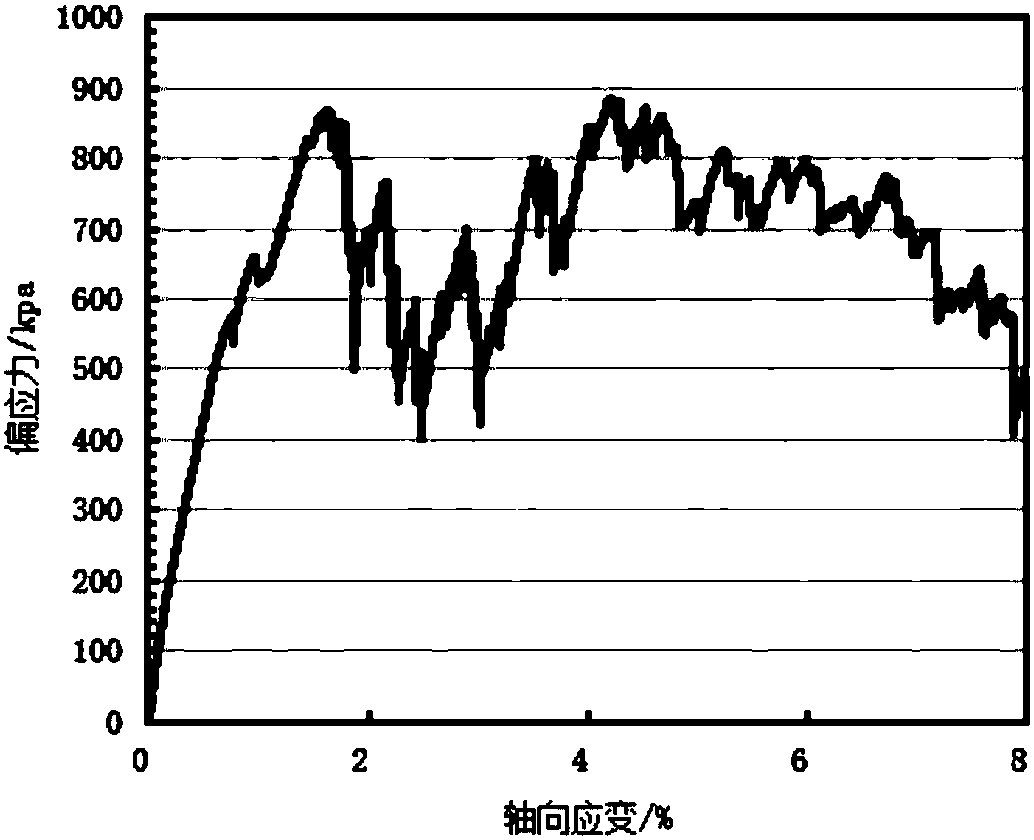

[0031] Such as figure 1 shown, including the following steps:

[0032] (1) Select 5 sample particles, the particle size should be between 19-26.5mm, and the angular shape is relatively obvious. At the same time, the length of the selected sample particles should not be greater than 2.4 times the particle size, and the thickness should not be less than the particle size 0.4 times;

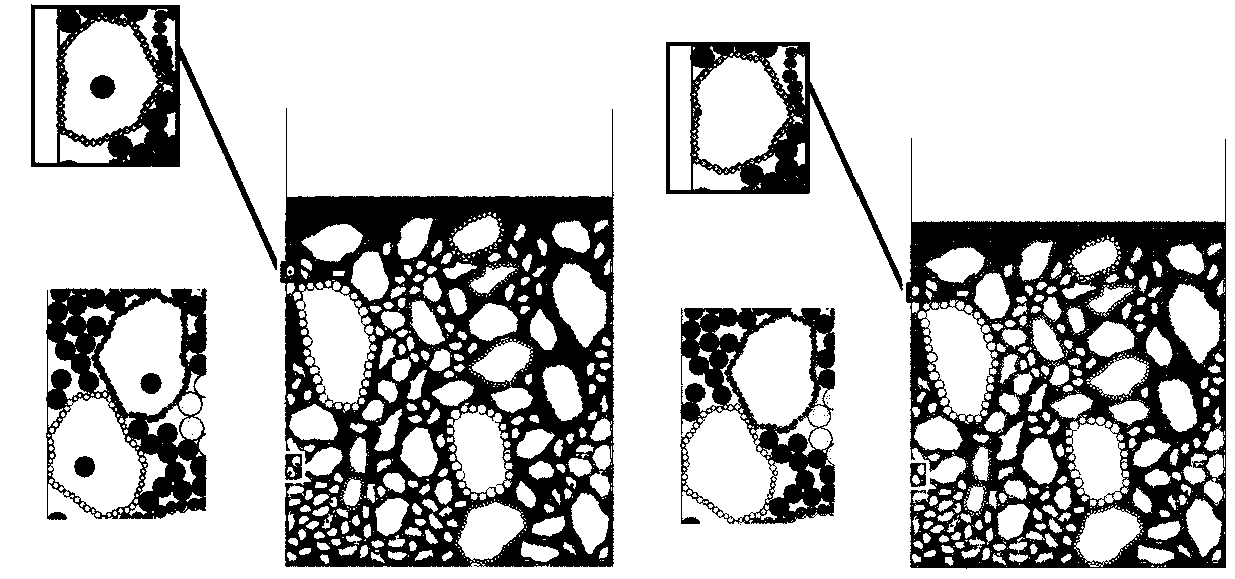

[0033] (2) Virtual modeling of coarse aggregate particles: Obtain the contour coordinates of five sample particles through image processing technology, scale all the coordinate data to the coordinate data of particles with a particle size of 19mm, and perform certain edge screening, and The coordinate data after zooming and screening are imported into PFC2D, and the virtual particles with a particle size of 19mm are formed, and the control random number of each particle size is established...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com