Device for testing voltage resistance of plug

A technology of withstand voltage detection and detection device, which is applied in the direction of using liquid/vacuum for liquid tightness measurement, etc., can solve problems such as the decline of insulation performance, reduce the sealing area, save time and economic cost, and reduce the axial direction. The effect of thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

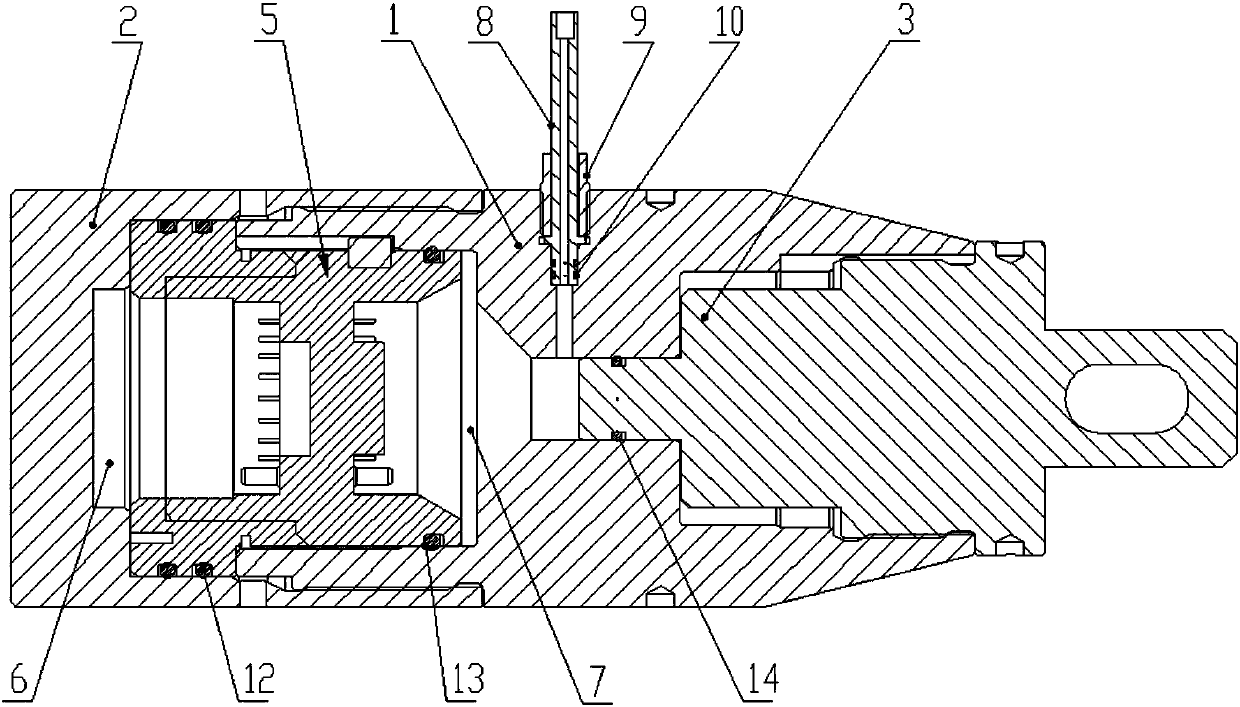

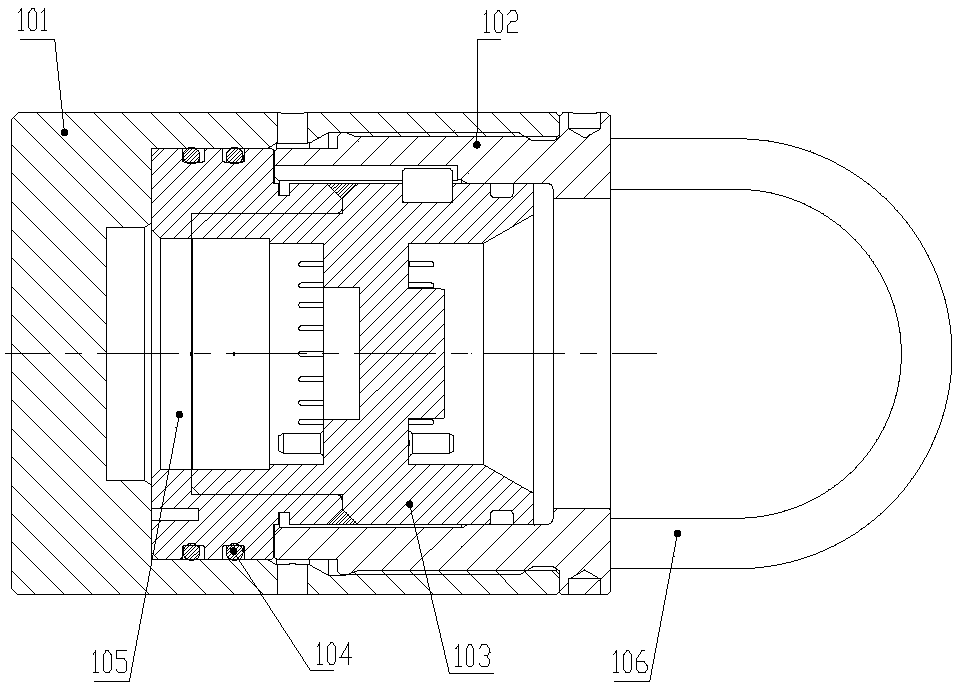

[0033] Such as figure 1 As shown, the present invention provides a plug pressure testing device, including a main body 1, a sealing outer casing 2, a sealing plug 3 and a pressurizing device. One end of the main body 1 is connected to the sealing outer casing 2 through threads, and the other end is connected to the sealing plug 3 connection, the joint between the sealing plug 3 and the main body 1 is installed with a plug sealing ring 14 for sealing, the sealing plug 3 is a stepped structure, and the outer diameter of the sealing surface is smaller than the outer diameter of the sealing plug 3; the main body 1 and the sealing A cavity for placing the detection plug 5 is formed between the jackets 2. The detection plug 5 divides the cavity into two parts: a low-pressure chamber 6 and a high-pressure chamber 7. A high-pressure chamber for sealing the detection plug 5 and the main body 1 is installed in the high-pressure chamber 7 A sealing ring 13, a low-pressure chamber sealin...

Embodiment 2

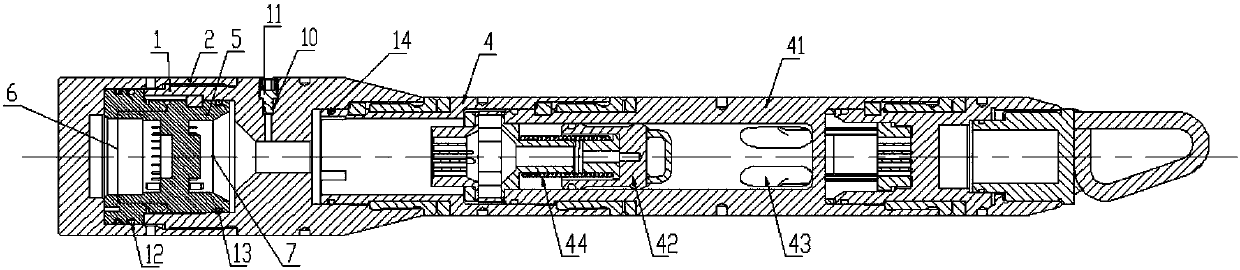

[0041] Such as figure 2 As stated above, the present invention replaces the sealing plug 3 in Embodiment 1 with a balance piston assembly 4, and the balance piston assembly 4 includes a balancing piston 42 located in the housing 41 and inside the housing 41 for the balance piston 42 to move along the radial direction of the balance piston assembly 41. Chamber 43, balance piston 42 connected with balance chamber 43 through spring 44, and the rest are the same as in embodiment 1.

[0042] The invention provides a plug withstand voltage detection device in a high-temperature and high-pressure well to conduct experiments at 140MPa and 175°C, including the following steps:

[0043] S5: Replace the sealing plug 3 with the balance piston assembly 4;

[0044] S6: Vacuumize the high-pressure chamber 7, inject silicone oil from the high-pressure oil pipe 8 into the high-pressure chamber 7 through the oil injection pump, and push the balance piston 42 to the rightmost side of the balance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com