Processing technique for preparing debitterized lemon seed oil by cold pressing

A technology of lemon seed oil and processing technology, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problems of lemon seed or its cutting fragments that cannot be fully utilized, pollution, etc., and achieve food safety. High economic value and the effect of avoiding losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further elaborated below by non-limiting examples. It should be understood, however, that these descriptions are exemplary only, and are not intended to limit the scope of the invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

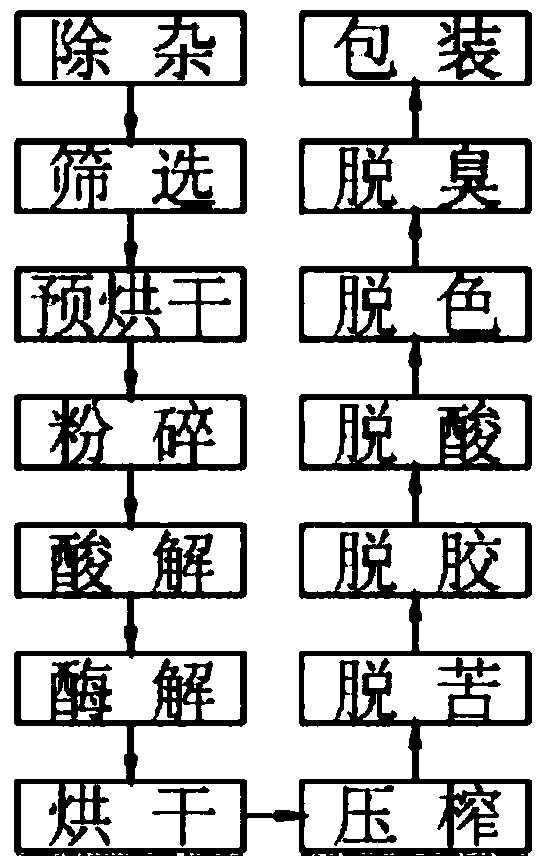

[0039] like figure 1 As shown, the company randomly purchases raw materials of crushed lemon seeds. The long diameter of crushed lemon seeds is 16.29-18.92mm, the short diameter is 21.87-26.85mm, and the water content is 21.4±1.97%. The following methods are used to prepare lemon seed cold-pressed edible oil:

[0040] 1) Impurity removal and screening: Spread the whole or broken lemon seed raw materials at room temperature (20°C) and dry the residual moisture on the surface with natural wind, then use a screen equipped with two layers (the upper layer is 20 mesh; the lower layer is 20 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Long trail | aaaaa | aaaaa |

| Short diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com