Degradable offset printing ink

A technology for offset printing ink and linseed oil, applied in the directions of ink, application, household appliances, etc., can solve the problems of environmental hazards, poor degradability, etc., and achieve the effects of high plasticization efficiency, low volatility and high degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

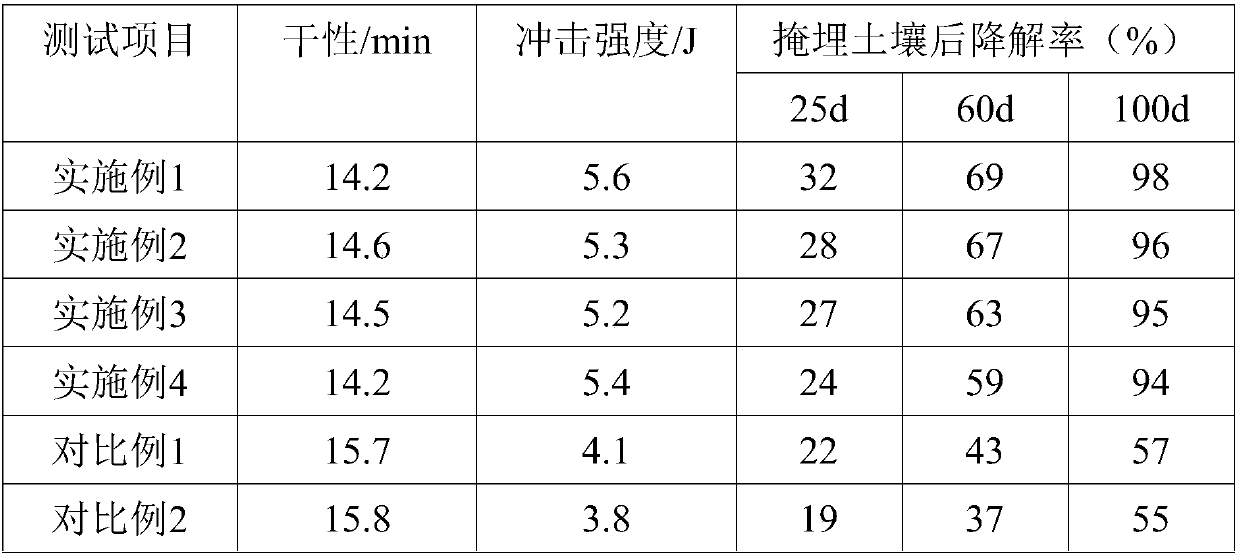

Examples

Embodiment 1

[0023] A degradable offset printing ink, comprising the following raw materials in parts by weight: 52 parts of PU-6011 water-based polyurethane, 22 parts of polylactic acid, 16 parts of carmine, 10 parts of linseed oil, 9 parts of rosin, and 5 parts of polypropylene carbonate , 2 parts of 4010 wetting and dispersing agent, 3 parts of RQT-P-1 plasticizer, 13 parts of additives, 6 parts of modified starch, 32 parts of ethyl acetate. The auxiliary agent includes the following raw materials in parts by weight: 13 parts of silicone leveling agent, 16 parts of anti-scratch and wear-resistant agent DC-5, 3 parts of 3045 defoamer, 1.3 parts of polymerization inhibitor ST-1, and 1 part of drier.

[0024] Among them, the preparation method of modified starch is as follows: configure 108 parts by weight of starch into starch aqueous solution, gelatinize at 85°C, add 4 parts by weight of azobisisobutyronitrile, and add 8 parts by weight of methacrylic acid after stirring Methyl ester, ke...

Embodiment 2

[0030] A degradable offset printing ink, comprising the following raw materials in parts by weight: 55 parts of PU-6011 water-based polyurethane, 18 parts of polylactic acid, 12 parts of titanium dioxide, 13 parts of linseed oil, 10 parts of rosin, and 4 parts of polypropylene carbonate , 2 parts of 4010 wetting and dispersing agent, 3 parts of RQT-P-1 plasticizer, 12 parts of additives, 4 parts of modified starch, 34 parts of ethanol. The additives include the following raw materials in parts by weight: 16 parts of silicone leveling agent, 7 parts of anti-scratch and wear-resistant agent DC-51, 4 parts of 3045 defoamer, and 1.6 parts of polymerization inhibitor ST-1.

[0031] Among them, the preparation method of modified starch is as follows: configure 110 parts by weight of starch into starch aqueous solution, gelatinize at 90°C, add 6 parts by weight of azobisisobutyronitrile, and add 10 parts by weight of methacrylic acid after stirring Methyl ester, keep warm for 3h, fil...

Embodiment 3

[0037] A degradable offset printing ink, comprising the following raw materials in parts by weight: 56 parts of PU-6011 water-based polyurethane, 26 parts of polylactic acid, 18 parts of indigo, 13 parts of linseed oil, 11 parts of rosin, 6 parts of polypropylene carbonate, 3 parts of 4010 wetting and dispersing agent, 5 parts of RQT-P-1 plasticizer, 14 parts of additives, 7 parts of modified starch, 35 parts of propyl acetate. The additives include the following raw materials in parts by weight: 20 parts of silicone leveling agent, 18 parts of anti-scratch and wear-resistant agent DC-5, 5 parts of 3045 defoamer, 2.3 parts of polymerization inhibitor ST-1, and 1.5 parts of drier.

[0038] Among them, the preparation method of modified starch is as follows: configure 116 parts by weight of starch into starch aqueous solution, gelatinize at 88°C, add 6 parts by weight of azobisisobutyronitrile, and add 10 parts by weight of methacrylic acid after stirring Methyl ester, keep warm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com