Preparation method of wood-grain brick with wood-knot effect

A technology of wood grain and wood knot, which is applied in the field of preparation of wood grain bricks, can solve the problem that wood grain bricks cannot have the simulation effect of wood knot, and achieve the effect of realistic wood knot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1

[0034] A method for preparing a wood-grained brick with a wood knot effect, comprising the following steps:

[0035] A. Preparation:

[0036] a1. According to the requirements of product color contrast and depth, two or more kinds of mud materials with basically the same drying rate and shrinkage rate and contrasting colors after calcination are equipped, among which the mud materials used as the background color account for 90%, and the mud materials used as textures account for 90%. 10%, moisture content is 15%;

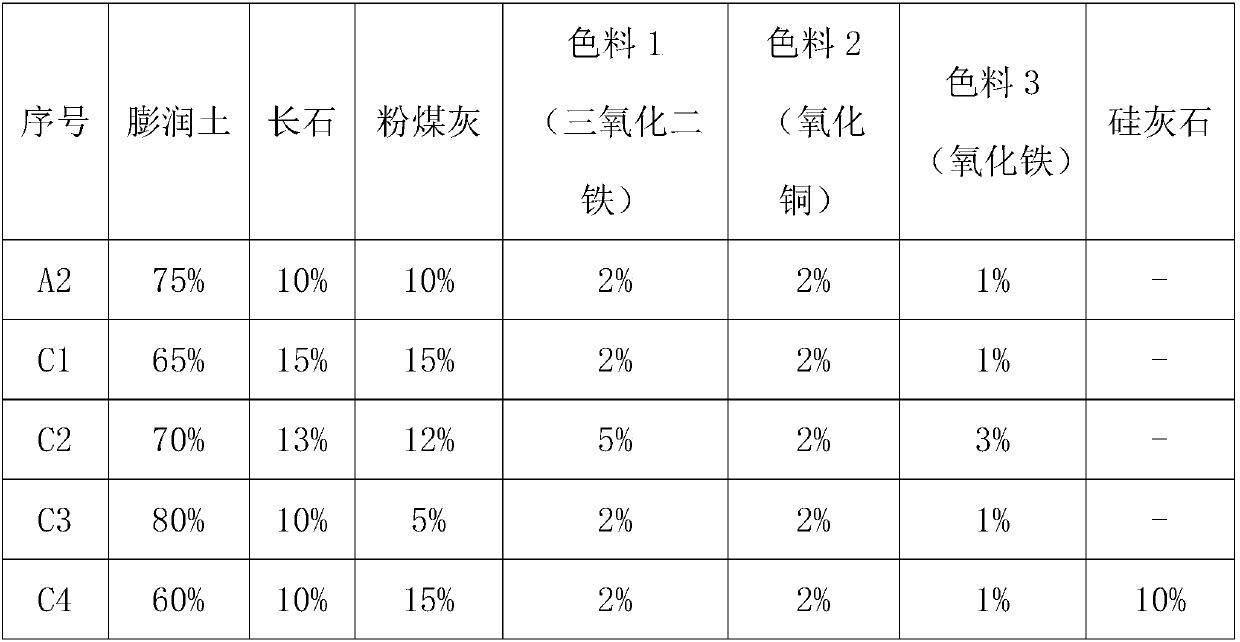

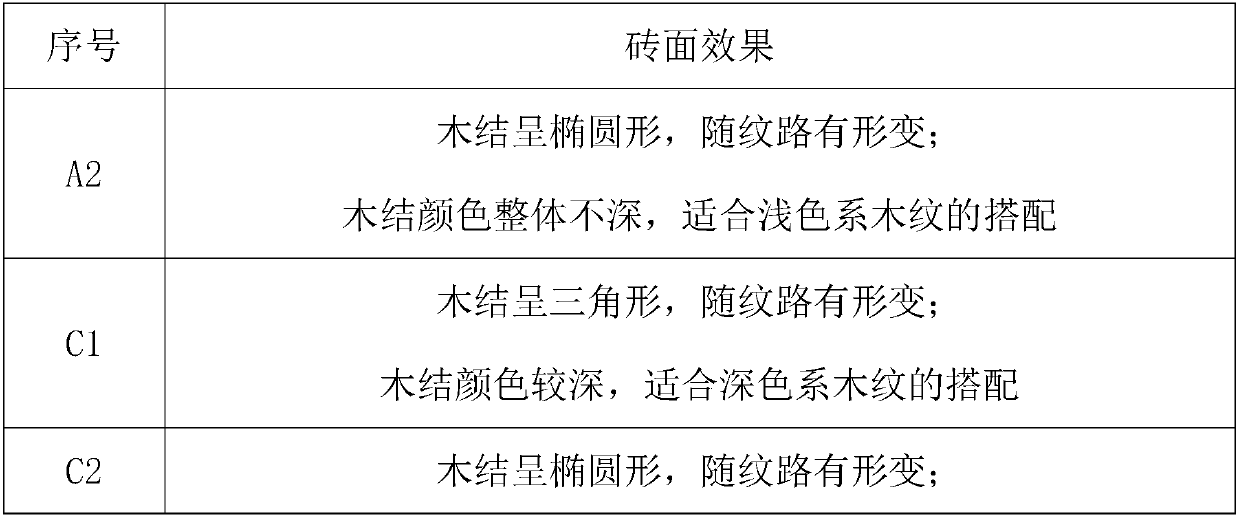

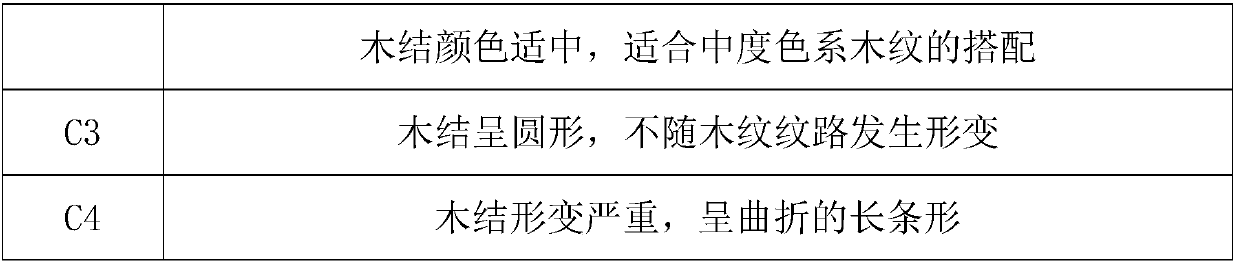

[0037] a2. Preparation of granules with unevenly mixed pigments, the water content of which is 10%-13%; wherein the formula of granules includes the following components in weight percentage: 75% bentonite, 10% feldspar, 10% fly ash , iron oxide 2%, ferric oxide 2% and copper oxide 1%; divide the three basic raw materials of bentonite, feldspar and fly ash into 3 parts, first add a part of the basic raw materials into the wet ball mill, and add three Ferric oxide...

Embodiment A2

[0043] A method for preparing a wood-grained brick with a wood knot effect, comprising the following steps:

[0044] A. Preparation:

[0045] a1. According to the requirements of product color contrast and depth, two or more kinds of mud materials with basically the same drying rate and shrinkage rate and contrasting colors after calcination are equipped, among which the mud materials used as the background color account for 90%, and the mud materials used as textures account for 90%. 10%, moisture content is 15%;

[0046] a2. Preparation of granules with unevenly mixed pigments, the water content of which is 10%-13%; wherein the formula of granules includes the following components in weight percentage: 75% bentonite, 10% feldspar, 10% fly ash , iron oxide 2%, ferric oxide 2% and copper oxide 1%; divide the three basic raw materials of bentonite, feldspar and fly ash into 3 parts, first add a part of the basic raw materials into the wet ball mill, and add three Ferric oxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com