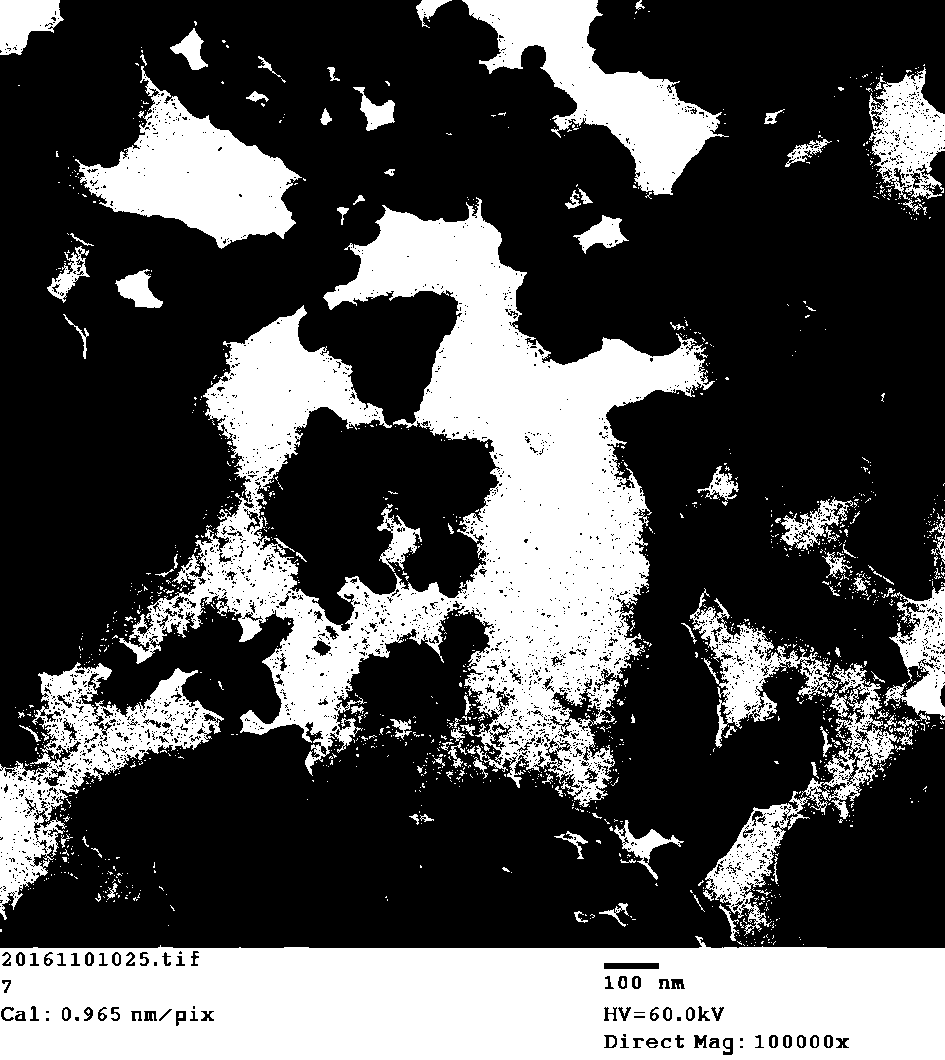

Preparation process of spindle-shaped nano calcium carbonate

A nano-calcium carbonate and preparation process technology, applied in the directions of calcium carbonate/strontium/barium, nanotechnology, calcium/strontium/barium compounds, etc., can solve the problem of low production efficiency, wide particle size distribution and poor uniformity of spindle-shaped nano-calcium carbonate and other problems, to achieve the effect of shortened carbonization reaction time, uniform particle size and stable production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Place weighed 100kg of quicklime with an activity of 420mL on the feeding platform of the digester; raise the temperature of 500kg of water to 60°C as digested water; turn on the digester; add the digested water to 2% of the effective digestion volume of the digester / 3, add water and quicklime to the remaining water, gradually add it into the digestion machine, stop the digestion for 45 minutes, and pass it through a 240-mesh circular vibrating sieve to obtain milk of lime.

[0030] (2) Maintain the condition of 20-25 ℃, adjust the concentration of lime milk to 8 degrees Baume, add Ca(OH) in lime milk 2 1.0% crystal form control agent A (industrial white sugar) and 0.8% crystal form control agent B (polyphosphate) on a dry basis to obtain an initial slurry.

[0031] (3) will be 0.08m 3 The initial slurry is pumped into the effective reaction volume of 0.08m 3 In the primary carbonization tower, high-purity carbon dioxide (concentration = 95% mixed gas, the rest ...

Embodiment 2

[0037] (1) Place weighed 100kg of quicklime with an activity of 380mL on the feeding platform of the digester; raise the temperature of 500kg of water to 60°C as digested water; turn on the digester; add the digested water to 2% of the effective digestion volume of the digester / 3, add water and quicklime to the remaining water, gradually add it into the digestion machine, stop the digestion for 40 minutes, and pass it through a 240-mesh circular vibrating sieve to obtain milk of lime.

[0038] (2) Maintain the condition of 20-25 ℃, adjust the concentration of lime milk to 8 degrees Baume, add Ca(OH) in lime milk 2 1.0% crystal form control agent A (industrial white sugar) and 0.8% crystal form control agent B (polyphosphate) on a dry basis to obtain an initial slurry.

[0039] (3) will be 0.08m 3 The initial slurry is pumped into the effective reaction volume of 0.08m 3 In the primary carbonization tower, carbon dioxide (concentration = 65% mixed gas, the rest is air) is i...

Embodiment 3

[0045] (1) Place weighed 100kg of quicklime with an activity of 360mL on the feeding platform of the digester; raise the temperature of 500kg of water to 60°C as digested water; turn on the digester; add digested water to 2% of the effective digestion volume of the digester / 3, add water and quicklime to the remaining water, gradually add it into the digestion machine, stop the digestion for 45 minutes, and pass it through a 240-mesh circular vibrating sieve to obtain milk of lime.

[0046] (2) Maintain the condition of 20-25 ℃, adjust the concentration of lime milk to 8 degrees Baume, add Ca(OH) in lime milk 2 1.0% crystal form control agent A (industrial white sugar) and 0.8% crystal form control agent B (polyphosphate) on a dry basis to obtain an initial slurry.

[0047] (3) will be 0.08m 3 The initial slurry is pumped into the effective reaction volume of 0.08m 3 In the primary carbonization tower, carbon dioxide (concentration = 32% mixed gas, the rest is air) is intro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com