Rubble carrying device for rare earth mining

A technology of handling device and transport device, which is used in transportation and packaging, multi-axis trolleys, trolley accessories, etc., can solve the problems of easy falling of crushed stones, waste, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

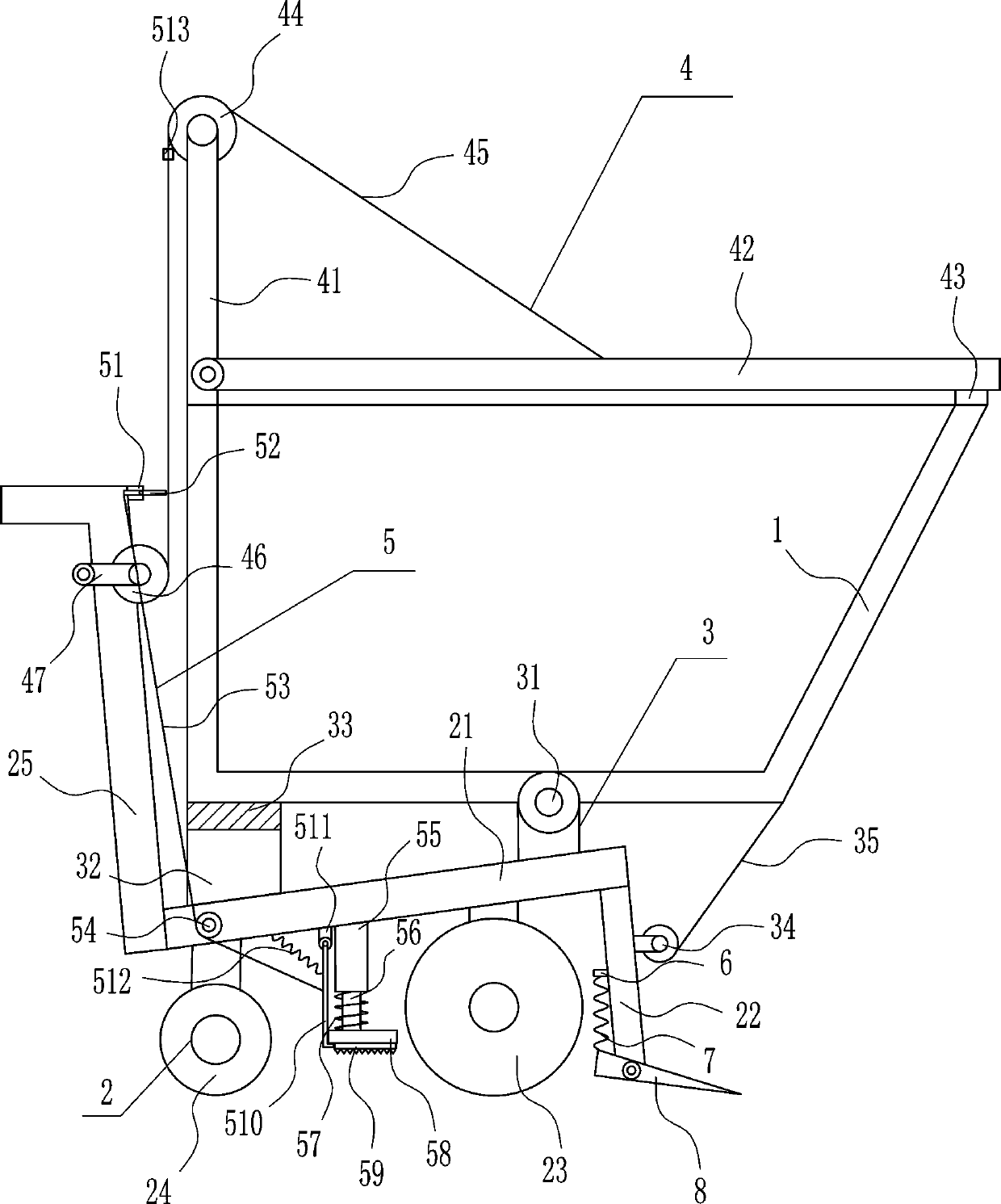

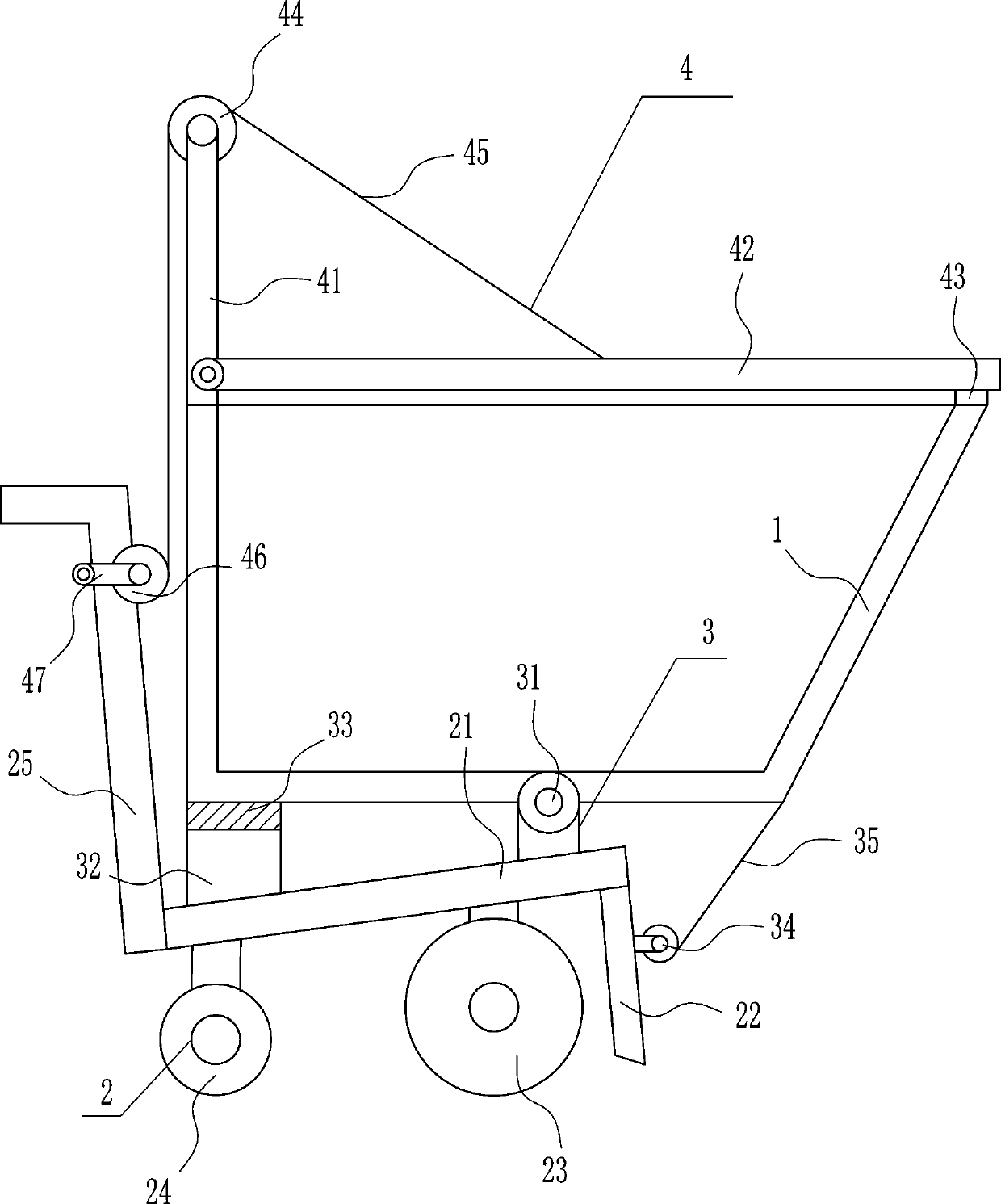

[0036] A gravel handling device for rare earth mining, such as Figure 1-6 As shown, it includes a hopper 1, a transportation device 2 and an overturning device 3. The transportation device 2 is provided with an overturning device 3, and the overturning part of the overturning device 3 is connected with a hopper 1, and the hopper 1 is located above the overturning device 3.

Embodiment 2

[0038] A gravel handling device for rare earth mining, such as Figure 1-6 As shown, it includes a hopper 1, a transportation device 2 and an overturning device 3. The transportation device 2 is provided with an overturning device 3, and the overturning part of the overturning device 3 is connected with a hopper 1, and the hopper 1 is located above the overturning device 3.

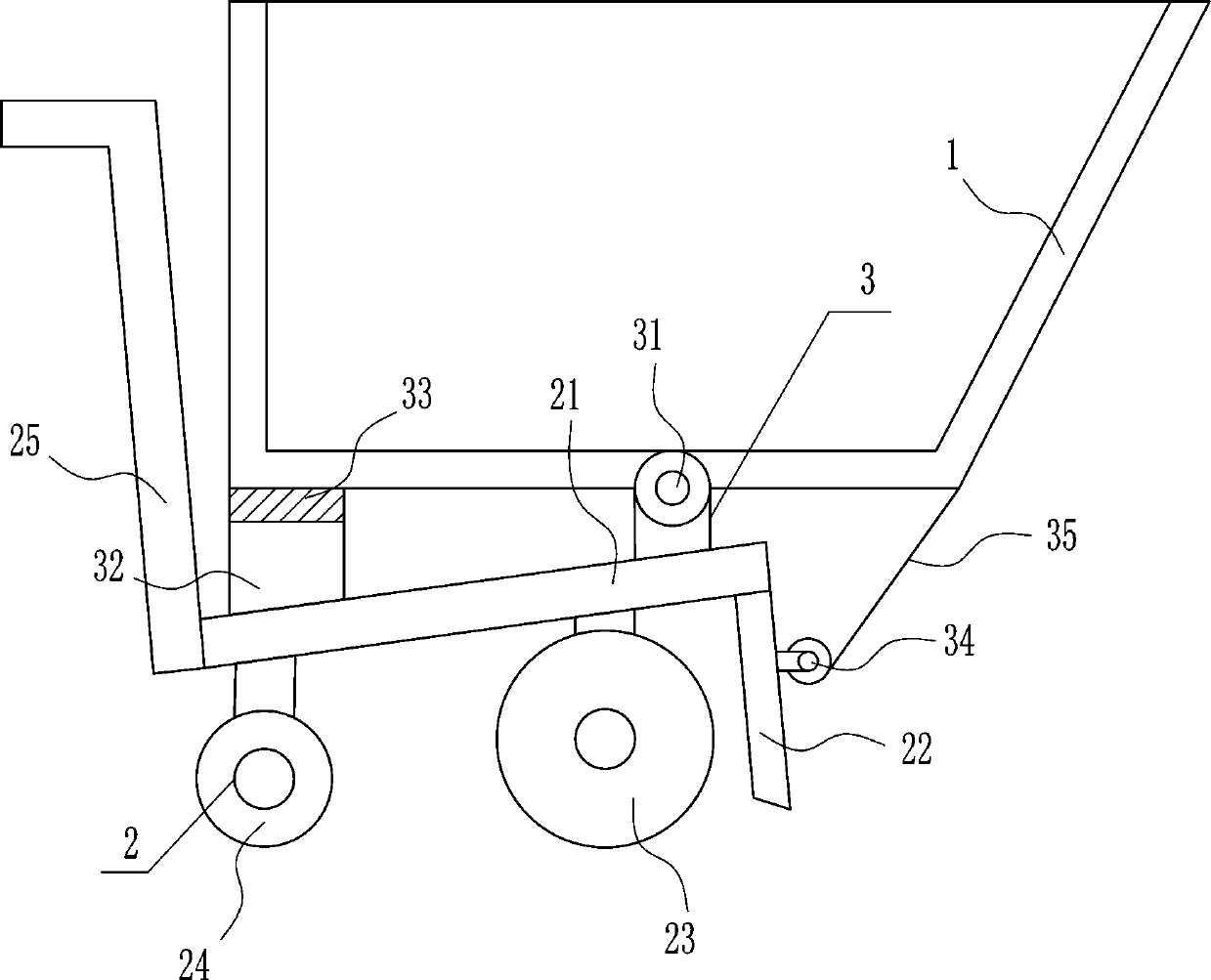

[0039] The transportation device 2 includes a base plate 21, a vertical plate 22, a large wheel 23, a small wheel 24 and a push handle 25. The top of the base plate 21 is connected with the turning device 3, and the left side of the base plate 21 is equipped with a push handle 25, which is located on the left side of the hopper 1. Bottom plate 21 bottom plate 21 right side is equipped with riser 22, and riser 22 right side is connected with the driving part of overturning device 3, and bottom plate 21 bottom right side is equipped with big wheel 23, and big wheel 23 is positioned at riser 22 left sides, an...

Embodiment 3

[0041] A gravel handling device for rare earth mining, such as Figure 1-6 As shown, it includes a hopper 1, a transportation device 2 and an overturning device 3. The transportation device 2 is provided with an overturning device 3, and the overturning part of the overturning device 3 is connected with a hopper 1, and the hopper 1 is located above the overturning device 3.

[0042] The transportation device 2 includes a base plate 21, a vertical plate 22, a large wheel 23, a small wheel 24 and a push handle 25. The top of the base plate 21 is connected with the turning device 3, and the left side of the base plate 21 is equipped with a push handle 25, which is located on the left side of the hopper 1. Bottom plate 21 bottom plate 21 right side is equipped with riser 22, and riser 22 right side is connected with the driving part of overturning device 3, and bottom plate 21 bottom right side is equipped with big wheel 23, and big wheel 23 is positioned at riser 22 left sides, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com