Paper barrel production device

A production device and paper tube technology, which is applied in the direction of cardboard winding articles, can solve the problems of low efficiency, many workers' operations, and low degree of automation, and achieve the effect of high efficiency, high degree of automation, and good gluing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

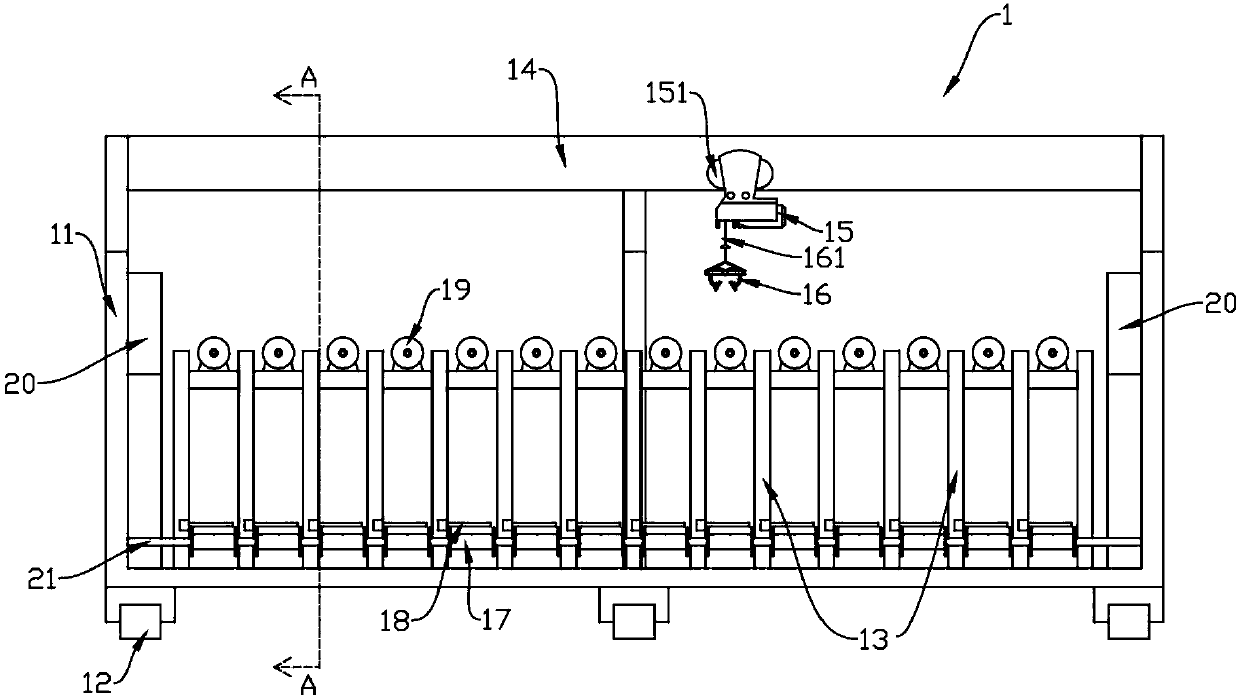

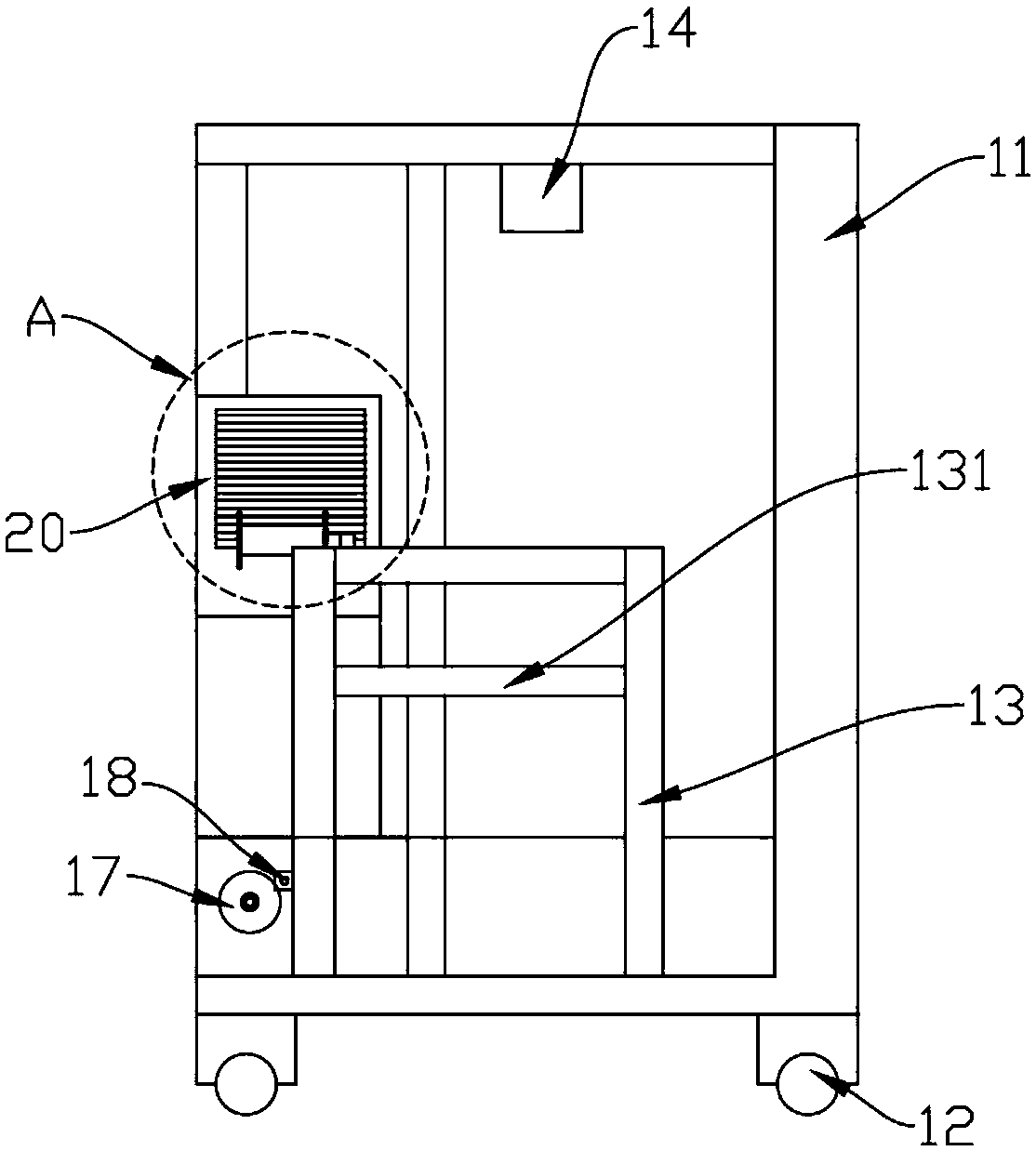

[0034] The paper tube production device in the present invention comprises a paper conveying device, a paper gluing device, a paper winding device and a roll paper tube cutting device connected in sequence.

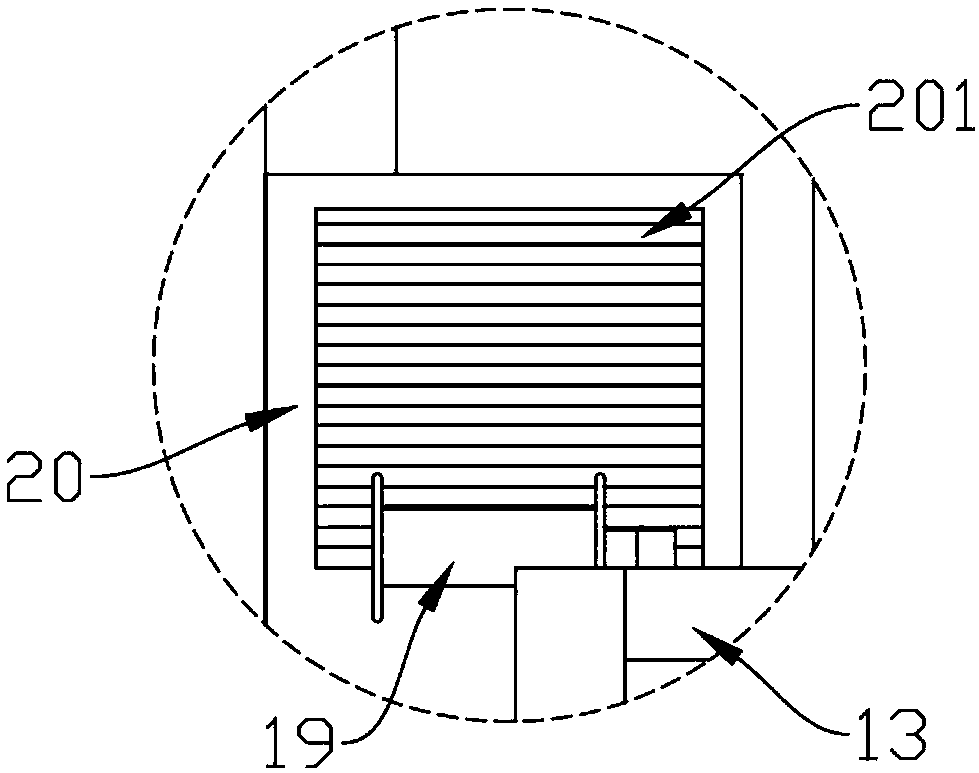

[0035] refer to Figure 1 to Figure 6 , the paper conveying device 1 involved in the present invention, the paper conveying device 1 includes a frame body 11 composed of several beams and vertical beams, the bottom of the frame body 11 is provided with wheels 12, and the frame body 11 is provided with several wheels in parallel. The roll paper placement frame 13, the roll paper placement frame 13 is provided with a shelving rod 131 for shelving the roll paper, the upper surface of the shelving rod 131 is provided with a symmetrical shelving groove 132, and the two shelving rods 131 A placement station for placing the roll paper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com