Equipment for producing latex mattresses by adopting high-frequency vulcanization and production process

A technology of high-frequency vulcanization and production technology, applied in applications, household components, household appliances, etc., can solve the problems of large energy consumption and waste discharge, poor stability, insufficient energy saving, environmental protection, etc., and achieve accurate control of moisture regain , Realize the effect of automation, continuity and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

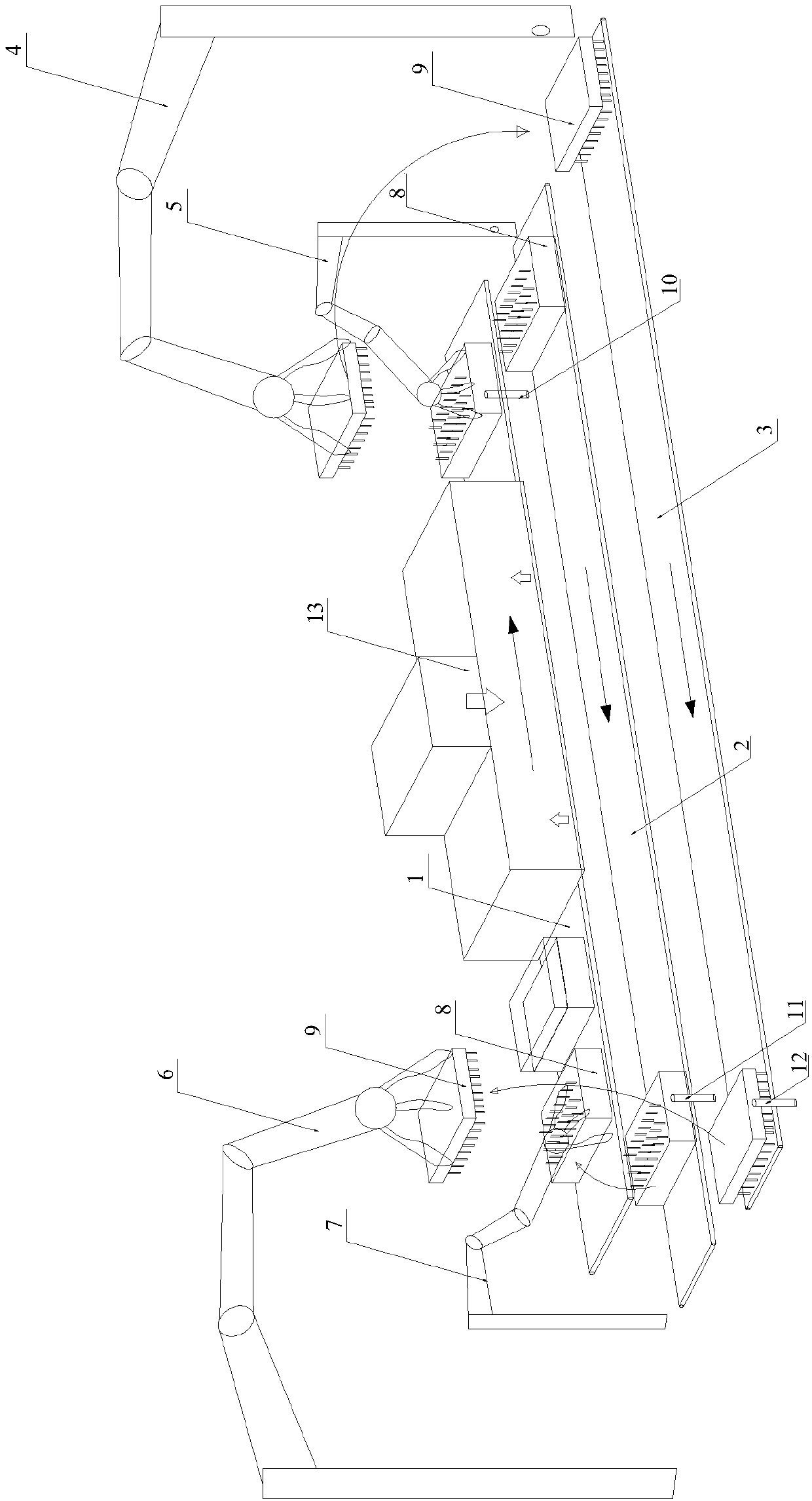

[0017] The present invention is further described below in conjunction with accompanying drawing:

[0018] A kind of equipment that adopts high-frequency vulcanization to produce latex mattress, comprises first conveyor belt 1, second conveyor belt 2 and third conveyor belt 3 arranged in parallel, and described second conveyor belt 2 is positioned at described first conveyor belt 1 and third conveyor belt 3, the surface of the first conveyor belt 1, the second conveyor belt 2 and the third conveyor belt 3 places a mold, the mold includes an upper mold 8 and a lower mold 9, and a high frequency is provided above the middle of the first conveyor belt 1. Heater 13, described lower mold 9 adopts metal material and is used as the cathode of high-frequency heater 13, and the right side area of conveyor belt is provided with manipulator A 4 and manipulator B 5, and the left side area of conveyor belt is provided with manipulator C 6 and manipulator D 7. The side of the first conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com