Hard contact lens care solution

A contact lens and care solution technology, applied in lens cleaning compositions, surface active detergent compositions, biocides, etc., to achieve the effects of avoiding irritation, prolonging service life, and strong antibacterial broad-spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

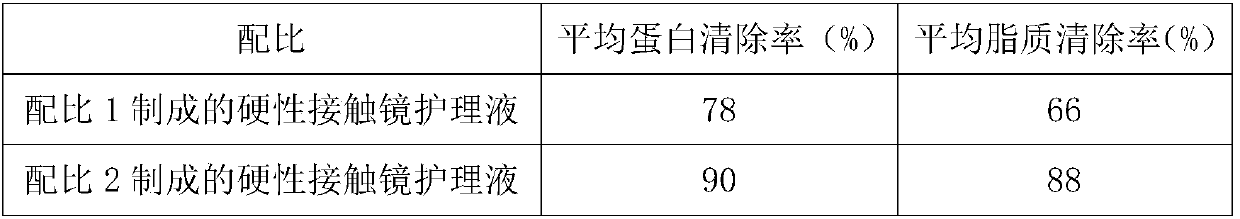

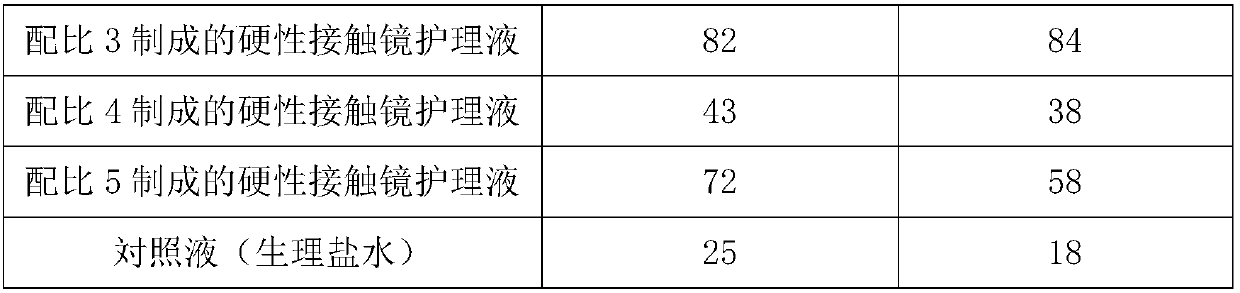

Examples

Embodiment

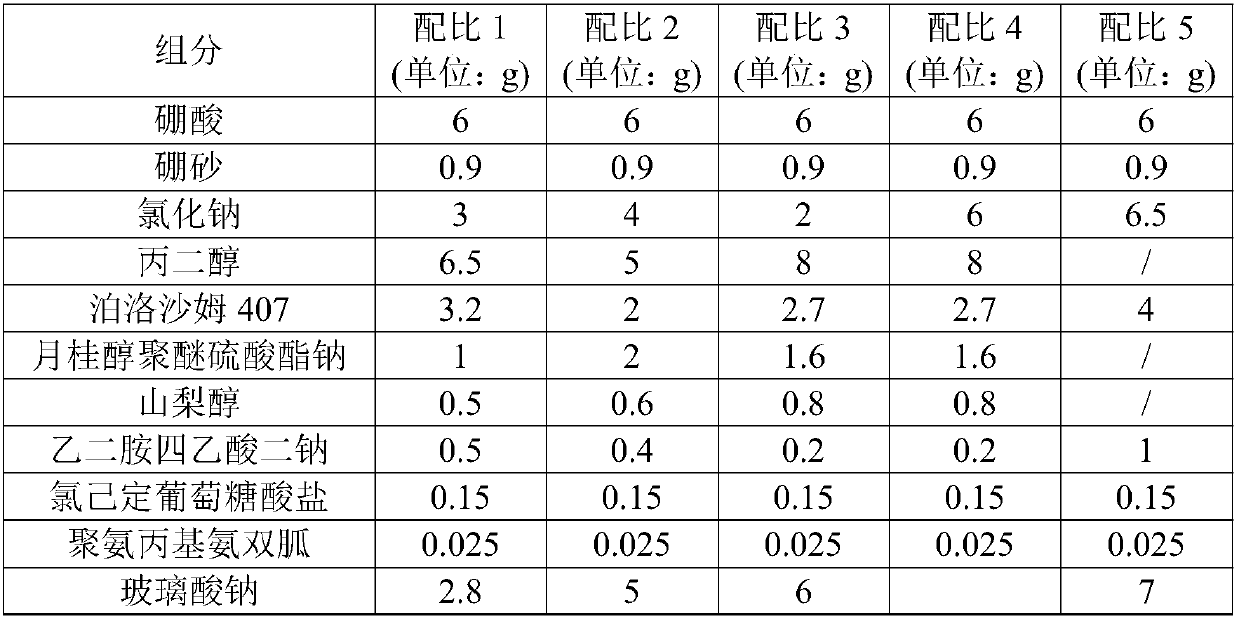

[0023] 1. Formula of hard contact lens care solution

[0024] Hard contact lens care solution among the present invention comprises:

[0025] Buffer: boric acid buffer (containing boric acid and borax);

[0026] Osmotic pressure regulator: propylene glycol, sodium chloride;

[0027] Cleanser: Poloxamer 407, Sodium Laureth Sulfate, Sorbitol, Disodium EDTA;

[0028] Disinfectants: chlorhexidine gluconate, polyaminopropyl aminobiguanide;

[0029] Thickener: sodium hyaluronate.

[0030] The specific ratio is as follows:

[0031]

[0032] 2. Preparation steps of hard contact lens care solution:

[0033] Weigh the specified amount of sodium hyaluronate according to the ratio 1-5 in the formula of the hard contact lens care solution, disperse it in the heated water for injection and stir, pre-dissolve for 40-60 minutes, stop stirring, and limit swelling After 1-2 hours, perform intermittent stirring; weigh a specified amount of sorbitol and add it to the aqueous solution, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com