Online indirect air cooling high-back-pressure heat supply machine unit back pressure control system and method

A technology for heating units and control systems, applied in engine control, mechanical equipment, steam engine installations, etc., can solve problems such as the inability of back pressure to effectively achieve DCS online adjustment, insufficient back pressure value optimization, and impact on unit safety, etc. Thermal economic benefits, improvement of dynamic regulation process, effect of optimized configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

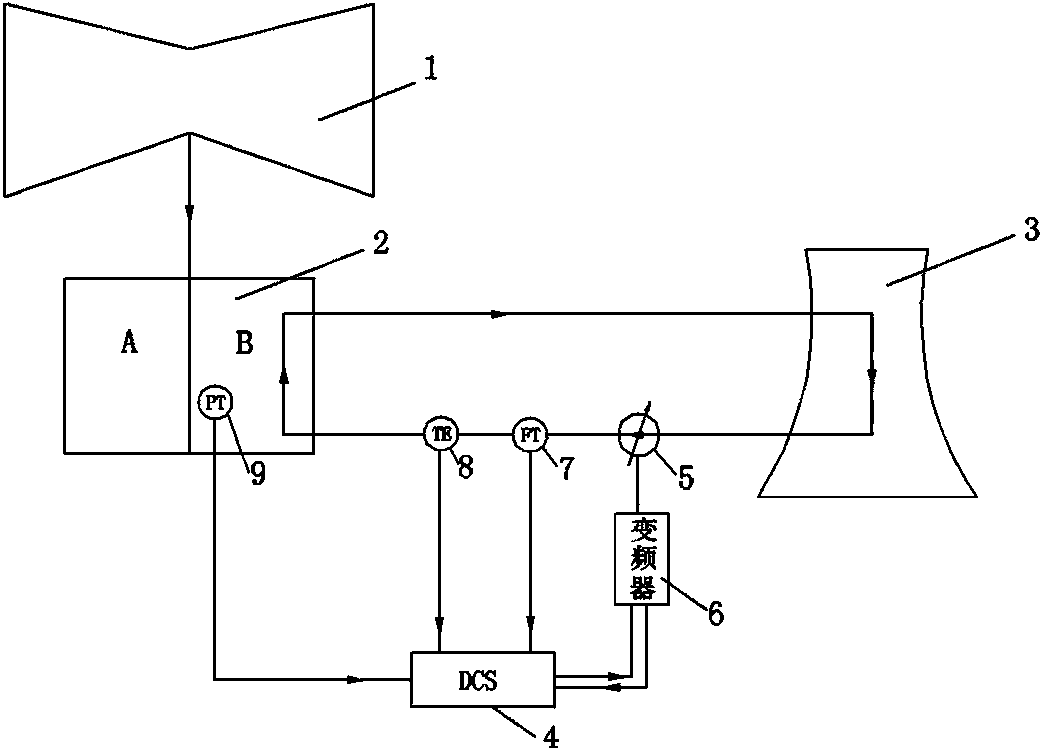

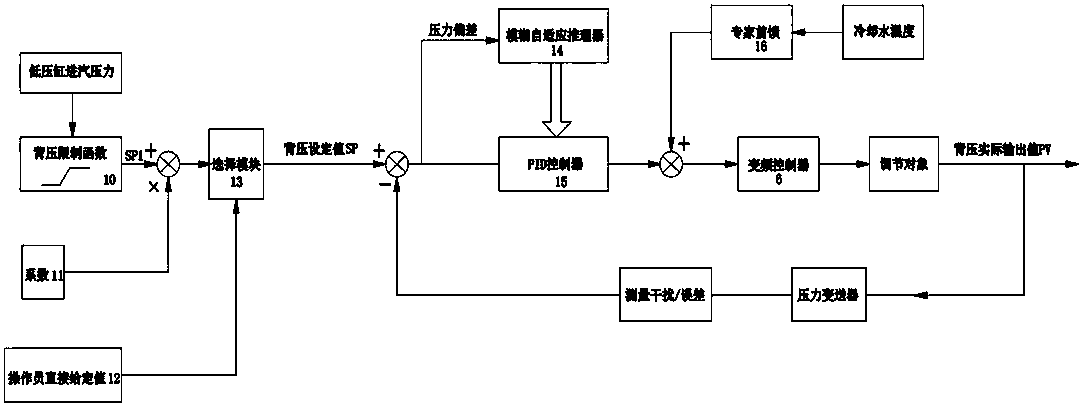

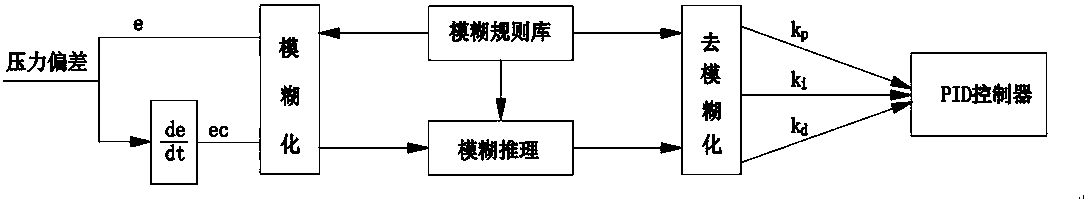

[0027] see figure 1 The equipment of the back pressure control system of the indirect air-cooled high back pressure heating unit provided by the present invention includes a steam turbine low pressure cylinder 1, a dual temperature zone condenser 2, an intercooling tower 3, a DCS control system 4, a frequency conversion circulating water pump 5, and a frequency converter 6. Flow measurement device 7, thermal resistance 8, pressure transmitter 9.

[0028] Under the condition of high back pressure heating, the cooling medium of side A of the dual temperature zone condenser 2 is circulating water of the heating network, and the cooling medium of side B is circulating water, and the variable frequency circulating water pump 5 is retrofitted in the original expansion unit for high back pressure heating. The newly added water pump on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com