Steel-FRP (fiber reinforced plastic) composite corrugated plate tunnel supporting method

A technology of corrugated plates and tunnels, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of inability to meet the corrosion requirements of tunnel engineering, poor corrosion resistance of steel, and low elastic modulus, etc. The effect of digging area, reducing steel corrosion, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The process flow of the composite material tunnel support method includes: prefabricated corrugated boards, reinforced surrounding rock with advanced small conduits, excavation on upper steps, installation of corrugated boards on the top, excavation on lower steps, installation of corrugated boards on side walls, excavation of inverted arches, inverted arches Corrugated plate fixing, waterproof and drainage system setting and secondary lining construction.

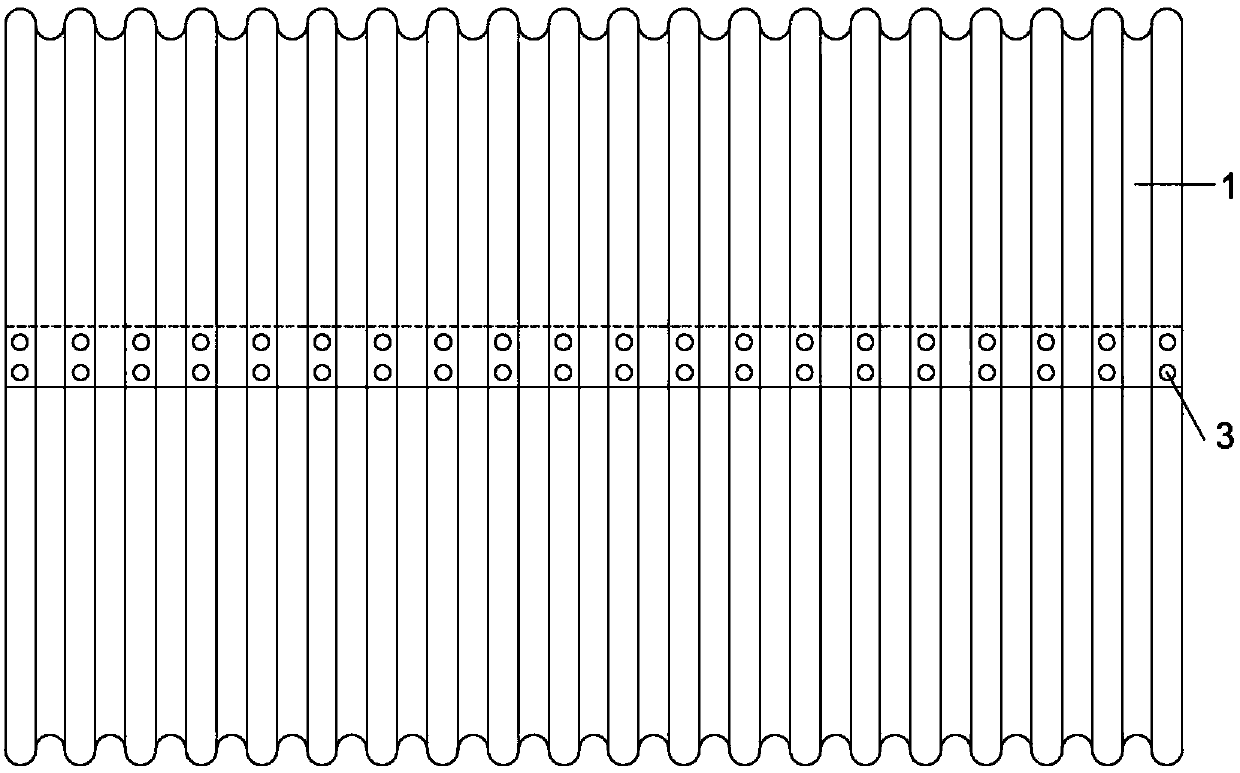

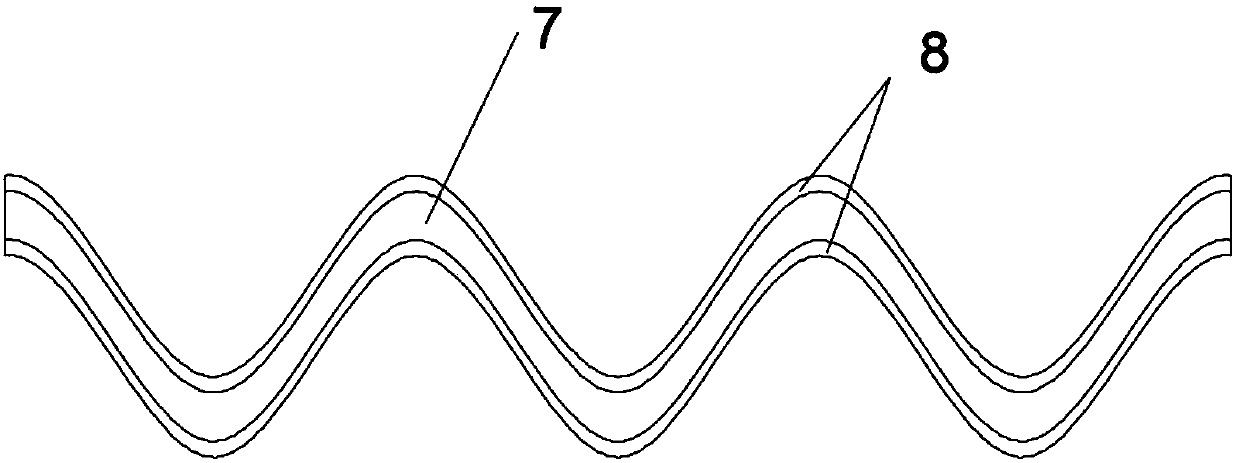

[0026] Such as figure 1 The shown tunnel support structure includes corrugated plate support 1 , anchor rod 2 , concrete layer 11 and secondary lining 5 . Corrugated plate support 1 is composed of top corrugated plates, side wall corrugated plates, inverted arch corrugated plates and concrete. The corrugated plates are connected into a ring as the main force-bearing member of the structure, and the corrugated plates are overlapped 3 and fixed by two rows of bolts at the overlapping positions. Each corrugated plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com