A multi-element alloyed aluminum alloy material, cylinder liner and preparation method thereof

A multi-element alloy and aluminum alloy technology, applied in the direction of cylinders, cylinder heads, mechanical equipment, etc., can solve the problems of complex formula composition, tensile strength to be improved, etc., and achieve the effect of compact structure, improved performance indicators, and increased tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The multi-element alloyed aluminum alloy cylinder liner of this embodiment is composed of the following components in weight percentage: 25% silicon, 6% magnesium, 0.5% titanium, 1% zirconium, and the balance is Al.

[0045] The preparation method of the multi-element alloyed aluminum alloy cylinder liner of this embodiment comprises the following steps:

[0046] 1) Heat crystalline silicon, aluminum block, magnesium block, Al-10Ti master alloy, and zirconium block to 850°C for melting to obtain an aluminum alloy melt;

[0047] After the aluminum alloy melt drops to 780°C, add a refining agent to refine the aluminum alloy melt. After refining, heat the aluminum alloy melt to 830°C and add a modifier for modification. The process of smelting, refining and modification is uniform Carry out slagging treatment and carry out under the protection of argon; stand still for 10 minutes after modification treatment to obtain aluminum alloy melt;

[0048] The refining agent used ...

Embodiment 2

[0053] The multi-element alloyed aluminum alloy cylinder liner of this embodiment is composed of the following components in weight percentage: 25% silicon, 6% magnesium, 0.5% titanium, 1% zirconium, and the balance is Al.

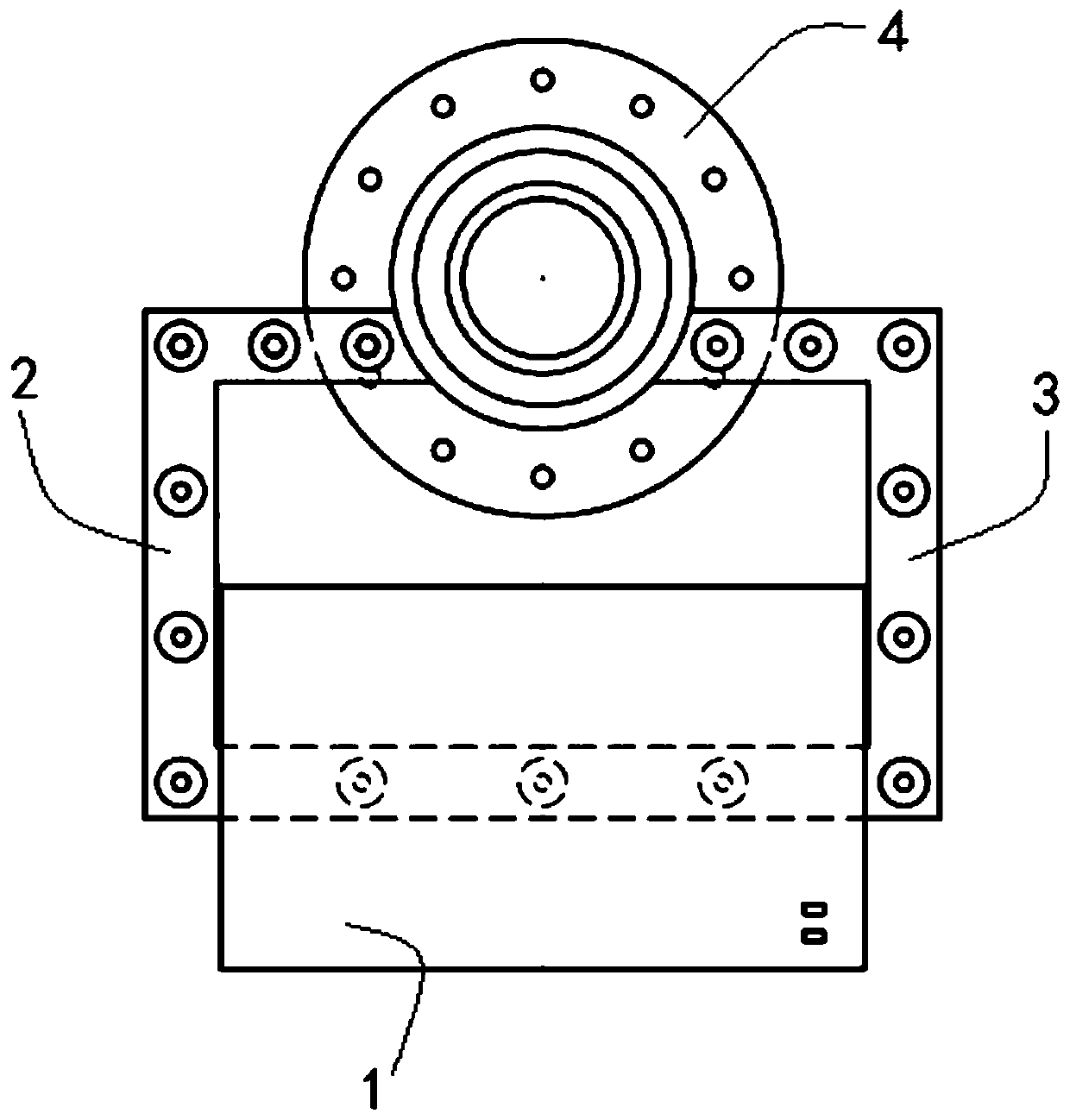

[0054] The preparation method of the multi-element alloyed aluminum alloy cylinder liner of the present embodiment adopts figure 1 The electromagnetic centrifugal casting equipment shown comprises the following steps:

[0055] 1) Heat crystalline silicon, aluminum block, magnesium block, Al-10Ti master alloy, and zirconium block to 850°C for melting to obtain an aluminum alloy melt;

[0056] After the aluminum alloy melt drops to 780°C, add a refining agent to refine the aluminum alloy melt. After refining, heat the aluminum alloy melt to 830°C and add a modifier for modification. The process of smelting, refining and modification is uniform Carry out slagging treatment and carry out under the protection of argon; stand still for 10 minutes after modifica...

Embodiment 3~4

[0060] The multi-element alloyed aluminum alloy cylinder liners of Examples 3-4 have the same composition as that of Example 1.

[0061] The preparation method of the multi-element alloyed aluminum alloy cylinder liner of Examples 3-4 is basically the same as that of Example 2, except that the magnetic field strengths are 0.1T and 0.2T respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com