Inner wall heat-preservation flame-retardant diatom ooze and preparation method

A diatom mud and flame-retardant technology, which is applied in fire-resistant coatings, buildings, coatings, etc., can solve problems such as uneven quality, weak flame retardancy, and poor adhesion, and achieve good color matching and coating film Rugged, dielectric properties for good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

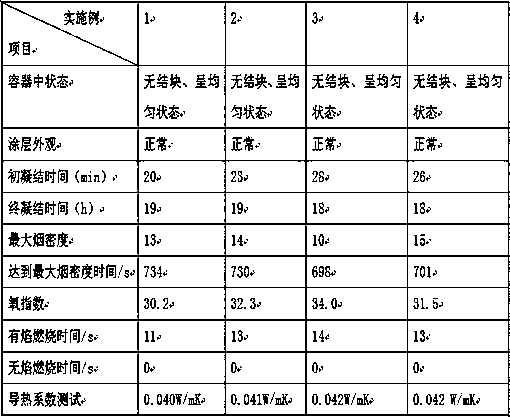

Examples

Embodiment 1

[0078] The preparation method of fire-retardant diatom mud for interior wall insulation includes the following raw materials in parts by weight: 60 parts of diatomite, 10 parts of ramie fiber, 15 parts of epoxy resin, 3 parts of composite coupling agent, and 5 parts of vermiculite powder , 5 parts of barium sulfate, 2 parts of chlorinated paraffin, 15 parts of pigment, 5 parts of flame retardant, 2 parts of defoamer, 1 part of thickener, 2 parts of dispersant; 2 parts of wetting agent AP-680, 40 parts of water share;

[0079] The preparation process of the fire-retardant diatom mud for interior wall insulation includes the following steps:

[0080] (1) Add parts by weight of pigment, flame retardant, 1 / 2 defoamer, thickener, dispersant, wetting agent AP-680, 1 / 3 water, mix and stir until uniform , the rotating speed is 300 rpm, stirring for 10 minutes;

[0081] (2), add vermiculite powder, barium sulfate, chlorinated paraffin to step (1), mix and stir, stir evenly, the speed...

Embodiment 2

[0091] The preparation method of fire-retardant diatom mud for interior wall insulation includes the following raw materials in parts by weight: 70 parts of diatomite, 10 parts of ramie fiber, 20 parts of epoxy resin, 4 parts of composite coupling agent, and 6 parts of vermiculite powder , 7 parts of barium sulfate, 3 parts of chlorinated paraffin, 17 parts of pigment, 7 parts of flame retardant, 2 parts of defoamer, 2 parts of thickener, 3 parts of dispersant; 2 parts of wetting agent AP-680, 50 parts of water share;

[0092] The preparation process of the fire-retardant diatom mud for interior wall insulation includes the following steps:

[0093] (1) Add parts by weight of pigment, flame retardant, 1 / 2 defoamer, thickener, dispersant, wetting agent AP-680, 1 / 3 water, mix and stir until uniform , with a rotating speed of 300 rpm, stirring for 12 minutes;

[0094] (2), add vermiculite powder, barium sulfate, chlorinated paraffin to step (1), mix and stir, stir evenly, the r...

Embodiment 3

[0104] The preparation method of fire-retardant diatom mud for interior wall insulation includes the following raw materials in parts by weight: 80 parts of diatomite, 15 parts of ramie fiber, 25 parts of epoxy resin, 5 parts of composite coupling agent, and 8 parts of vermiculite powder , 8 parts of barium sulfate, 4 parts of chlorinated paraffin, 18 parts of pigment, 9 parts of flame retardant, 3 parts of defoamer, 2 parts of thickener, 4 parts of dispersant; 3 parts of wetting agent AP-680, 55 parts of water share;

[0105] The preparation process of the fire-retardant diatom mud for interior wall insulation includes the following steps:

[0106](1) Add parts by weight of pigment, flame retardant, 1 / 2 defoamer, thickener, dispersant, wetting agent AP-680, 1 / 3 water, mix and stir until uniform , the rotating speed is 400 rpm, stirring for 15 minutes;

[0107] (2), add vermiculite powder, barium sulfate, and chlorinated paraffin to step (1), mix and stir, stir evenly, the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com