A method for refining and purifying caprolactam

A caprolactam and process water technology, which is applied in the field of caprolactam refining and purification, can solve the problems of difficulty in ensuring stable product quality, large discharge of ion exchange waste liquid, and high safety risk in the hydrogenation process, achieving improved safety and reduced production costs , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

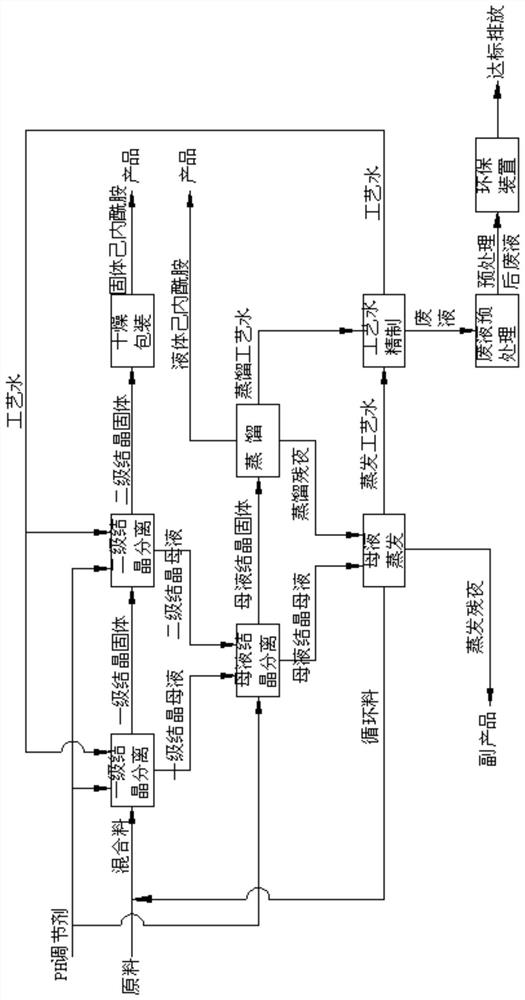

[0026] see figure 1 The schematic diagram of the process flow of the present invention provided, the preparation method of the present invention comprises the following steps:

[0027] (1) Primary crystallization and separation

[0028] Continuously add process water into the first-stage crystallization tank (stirring type) at a flow rate of 1kg / h, and at the same time continuously add the mixture at a flow rate of 80kg / h; the mass ratio of the raw material to the recycled material in the mixture is 1:1, and the raw material It is a caprolactam aqueous solution with a water content of 28% (wt) (feeding material for a benzene extraction tower in a caprolactam factory), and the recycle material is a water-containing 210ppm (wt) caprolactam liquid (from step 6 of the present invention). Control the temperature in the primary crystallization tank to be 27°C, the pressure to be normal pressure, the liquid level to be 55%, the pH value to be 11.5 (the pH regulator is an aqueous sod...

Embodiment 2

[0042] see figure 1 The schematic diagram of the process flow of the present invention provided, the preparation method of the present invention comprises the following steps:

[0043] (1) Primary crystallization and separation

[0044] Continuously add process water into the first-stage crystallization tank (stirring type) at a flow rate of 8kg / h, and at the same time continuously add the mixture at a flow rate of 80kg / h; the mass ratio of the raw material to the recycled material in the mixture is 2.5:1, and the raw material It is the caprolactam solution containing water 260ppm (wt) (the distillation raffinate of a certain caprolactam factory distillation unit), and the recycle material is the caprolactam liquid containing water 320ppm (wt) (from step 6 of the present invention). Control the temperature in the first-stage crystallization tank to be 26°C, the pressure to be normal pressure, the liquid level to be 57%, the pH to be 6.2 (the pH regulator is an aqueous solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com