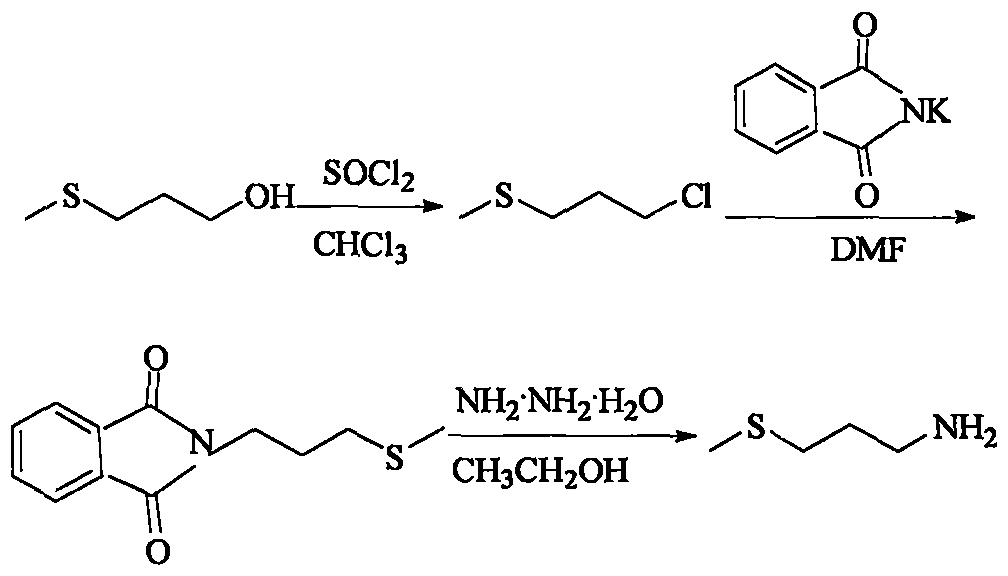

Method for preparing 3-methylthio propylamine

A technology of methylthiopropylamine and methylthiopropylphthalimide, which is applied in the fields of sulfide preparation and organic chemistry, and can solve problems such as inconvenient operation, low total yield, and low yield , achieve the effects of shortened reaction time, low reaction temperature and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Put the 250mL three-necked flask equipped with a reflux condenser (connected to the drying tube) and a constant pressure dropping funnel into a microwave ultrasonic combined synthesizer, and add a certain amount of 42.4g 3-methylthiopropanol and 70mL chloroform to the three-necked flask , set the microwave power to 500w, and the ultrasonic power to 400w. After the microwave-ultrasonic combined synthesizer starts to work, after the mixture is refluxed, slowly drop the mixture of 57.2g of thionyl chloride and 30mL of chloroform into the three ports through a constant pressure dropping funnel. In the flask; after the dropwise addition, continue the reflux reaction for 30min. After the reaction was finished, rotary evaporation removed unreacted raw materials and solvent chloroform in the reaction mixture, and the content of 3-methylthio-1-chloropropane was analyzed by gas chromatography, and its yield was calculated to be 95.2%; under reduced pressure, 33 to 37 The distilla...

Embodiment 2

[0025] Put the 500mL three-necked flask equipped with a reflux condenser (connected to the drying tube) and a constant pressure dropping funnel into a microwave ultrasonic combined synthesizer, and add a certain amount of 84.8g 3-methylthiopropanol and 150mL chloroform to the three-necked flask , set the microwave power to 600w, the ultrasonic power to 500w, and the microwave-ultrasonic combined synthesizer starts to work. After the mixture is refluxed, slowly drop the mixture of 114.4g of thionyl chloride and 60mL of chloroform into the three-necked flask through the constant pressure dropping funnel After the dropwise addition, continue the reflux reaction for 40min. After the reaction was finished, rotary evaporation removed unreacted raw materials and solvent chloroform in the reaction mixture, and the content of 3-methylthio-1-chloropropane was analyzed by gas chromatography, and its yield was calculated to be 95.6%; vacuum distillation collected 33 to 37 The distillate a...

Embodiment 3

[0029] The 1000mL three-necked flask equipped with a reflux condenser (connected to the drying pipe) and a constant pressure dropping funnel is put into a combined microwave-ultrasonic synthesizer, and a certain amount of 170g 3-methylthiopropanol and 300mL chloroform are added to the three-necked flask, Set the microwave power to 800w, the ultrasonic power to 800w, and the microwave-ultrasonic combined synthesizer starts to work. After the mixture is refluxed, slowly drop the mixture of 230g of thionyl chloride and 120mL of chloroform into the three-necked flask through the constant pressure dropping funnel; After the dropwise addition, the reflux reaction was continued for 60 min. After the reaction was finished, rotary evaporation removed unreacted raw materials and solvent chloroform in the reaction mixture, and the content of 3-methylthio-1-chloropropane was analyzed by gas chromatography, and its yield was calculated to be 95.8%; vacuum distillation collected 33 to 37 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com