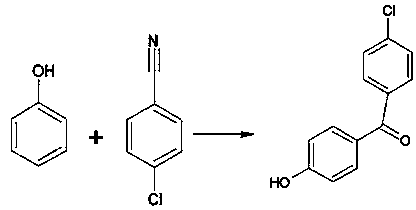

Preparation method of 4-chloro-4'-hydroxybenzophenone

A technology for hydroxybenzophenone and p-chlorobenzonitrile, which is applied in the field of compound preparation, can solve the problems of high industrialization cost, difficult source of raw materials, complicated routes, etc., and achieves the effects of low cost, simple reaction and easy recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The specific steps of the preparation method of 4-chloro-4'-hydroxybenzophenone in this embodiment include: adding 500 ml of dichloroethane, 100 g of phenol, 146 g of p-chlorobenzonitrile, and 20 g of anhydrous zinc chloride into the reaction kettle Stir with 5g of Dowex 50W resin produced by Dow Chemical, and control the temperature at 95°C to continuously feed dry hydrogen chloride gas. During the ventilation process, the reaction of the material is detected intermittently until the p-chlorobenzonitrile is completely reacted. Cool to room temperature and add concentration. It is 400ml of 30% hydrochloric acid aqueous solution, heated to reflux, reacted for 6h, until the hydrolysis of the intermediate is completed, then cooled to room temperature, layered, washed with water, dichloroethane is recovered from the organic layer, and the residue is added with 15% sodium hydroxide Dissolve 200ml of the aqueous solution, decolorize with 8g of activated carbon, acidify, filter...

Embodiment 2

[0019] The specific steps of the preparation method of 4-chloro-4'-hydroxybenzophenone in this embodiment include: adding 600 ml of dichloroethane, 120 g of phenol, 146 g of p-chlorobenzonitrile, and 25 g of anhydrous zinc chloride into the reaction kettle Stir with 8g of Dowex 50W resin produced by Dow Chemical, and control the temperature at 90°C to continuously feed dry hydrogen chloride gas. During the ventilation process, check the reaction of the material until the p-chlorobenzonitrile is completely reacted. Cool to room temperature and add concentration. It is 500ml of 30% hydrochloric acid aqueous solution, heated to reflux, reacted for 5h, until the hydrolysis of the intermediate is completed, then cooled to room temperature, layered, washed with water, dichloroethane is recovered from the organic layer, and the residue is added with 15% sodium hydroxide 250ml of the aqueous solution was dissolved, decolorized with 8g of activated carbon, acid-precipitated, suction fil...

Embodiment 3

[0021] The specific steps of the preparation method of 4-chloro-4'-hydroxybenzophenone in this embodiment include: adding 550 ml of dichloroethane, 120 g of phenol, 146 g of p-chlorobenzonitrile, and 22 g of anhydrous zinc chloride into the reaction kettle Stir with 7g of Dowex 50W resin produced by Dow Chemical, and control the temperature at 90°C to continuously feed dry hydrogen chloride gas. During the ventilation process, check the reaction of the material until the p-chlorobenzonitrile is completely reacted. Cool to room temperature and add concentration. It is 450ml of 30% hydrochloric acid aqueous solution, heated to reflux, reacted for 7h, until the hydrolysis of the intermediate is completed, then cooled to room temperature, layered, washed with water, dichloroethane is recovered from the organic layer, and the residue is added with 15% sodium hydroxide Dissolve 200 ml of the aqueous solution, decolorize with 8 g of activated carbon, acidify, filter with suction, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com