A purification method for deep dehydration and impurity removal of ethylene glycol adsorption extraction

A deep dehydration and ethylene glycol technology, applied in chemical instruments and methods, separation methods, solvent extraction, etc., can solve the problems of large separation coefficient, small flux, and other impurities, so as to solve desorption difficulties and large adsorption capacity. , the effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

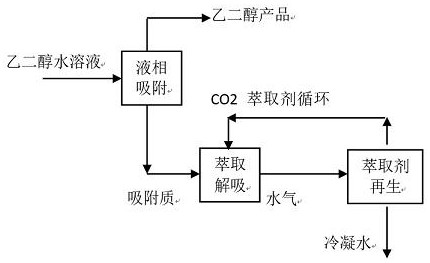

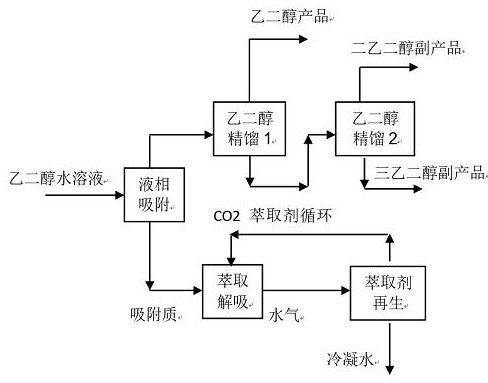

[0035] Such as figure 1 and figure 2 As shown, a purification method for deep dehydration and impurity removal of ethylene glycol adsorption extraction includes the following steps:

[0036] (1) Liquid-phase adsorption process, ethylene glycol aqueous solution containing 0.1-1.0% water (mass ratio, the same below), containing 0.1% trace impurities, such as acetaldehyde, formic acid, etc., as raw materials, the temperature is 30-40 ℃, the pressure is normal pressure, directly enters an adsorption tower in the liquid phase adsorption process composed of two adsorption towers from the top of the tower, and performs liquid phase adsorption at the adsorption temperature 30~40 ℃ and the adsorption pressure is normal pressure, water And trace impurities are used as the adsorbate, which is adsorbed by the adsorbent packed in the adsorption tower. After the adsorption is saturated, it enters the next step, the extraction and desorption process; the ethylene glycol is not adsorbed and...

Embodiment 2

[0044] Further optimized on the basis of a purification method for deep dehydration and impurity removal of ethylene glycol adsorption and extraction described in Example 1, the water content of the ethylene glycol aqueous solution is 15-20%, and the trace impurity content is still 0.1%. The temperature, pressure, etc. remain unchanged. Due to the increase of the water content in the raw material, at first, it is necessary to increase the loading amount of the adsorbent, and the loading amount of the A-type molecular sieve in the present embodiment is about 20% more than that in Example 1; secondly, the recycling amount of the extractant CCO needs to be increased; The 3rd, reduce the pressure in the extraction agent regeneration process to a lower level, down to the 1.0 ~ 3.0MPa range, so that more water and trace impurity components are fully separated from the CCO Extractant, or still maintain embodiment 1 The pressure range in the middle is 3.0~4.0MPa, and the temperature i...

Embodiment 3

[0046] On the basis of a purification method for deep dehydration and impurity removal of ethylene glycol adsorption and extraction described in Example 1, it is further optimized, the composition of the raw material gas remains unchanged, and the feed scale of the raw material ethylene glycol aqueous solution reaches 100,000 tons / year Above, the temperature is 70~90°C, the pressure is normal pressure, directly enter the liquid phase adsorption process, and the liquid phase adsorption is carried out in a system composed of 70~90°C operating temperature, adsorption pressure is normal pressure, and 4 adsorption towers. The 4 adsorption towers are connected in parallel 2-2 respectively, 2 adsorption towers absorb, and the other 2 adsorption towers extract and desorb, and the 2 groups of adsorption towers operate alternately to ensure the continuous entry of raw materials. In this embodiment, the temperature and processing capacity of the raw materials are increased and increased. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com