Double drying process sludge treatment apparatus

A sludge treatment and dry process technology, applied in sludge treatment, dewatering/drying/concentrated sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of long transportation distance, high operation cost and high transportation cost , to achieve the effect of high space utilization, saving processing investment and small land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

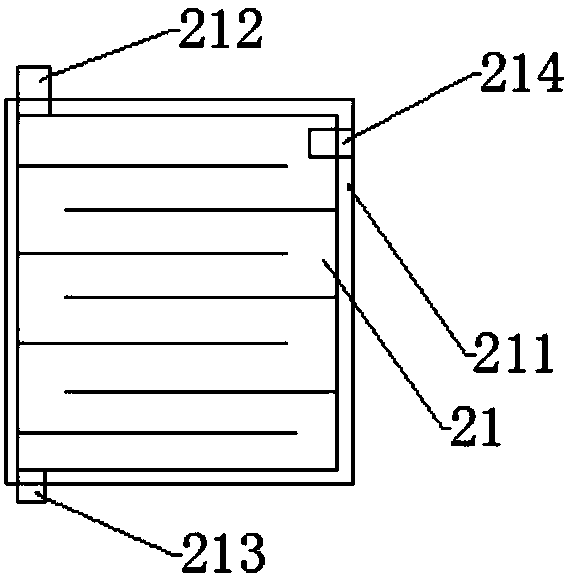

Embodiment 1

[0033] The double-dry sludge treatment device of this embodiment includes a stirring tank 1, a plate and frame filter press drier 2, a steam compressor 3, a dry distillation furnace 4 and a biochar storage bin 5, and the plate and frame filter press drier 2 is set Several filter press drying units are arranged, and the filter press drying unit comprises heating plate 21, and the both sides of heating plate 21 are provided with tympanum plate 22, and the both sides of tympanum plate 22 are provided with filter cloth 23, and tympanum plate 22 is close to one side of filter cloth 23. There are several protrusions on the side, and the cavity between the filter cloth 23 and the heating plate 21 is a drying chamber 24; the stirring tank 1 is connected with the drying chamber 24 of the filter press drying unit one by one through branch pipes, and feeds in parallel; The bottom of the drying unit is provided with a screw conveyor 6, the screw conveyor 6 is connected to the inlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com