Wood die positioning device for high-precision sand mould casting

A technology of sand casting and positioning device, which is applied in the field of high-precision sand casting wood mold positioning device and sand casting wood mold positioning device for precise positioning, can solve the problems of positioning device positioning accuracy and low life, and achieve good popularization and application. Value, high precision, less wear and bruise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

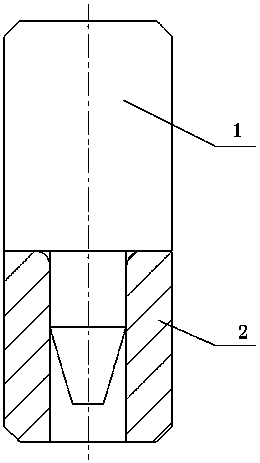

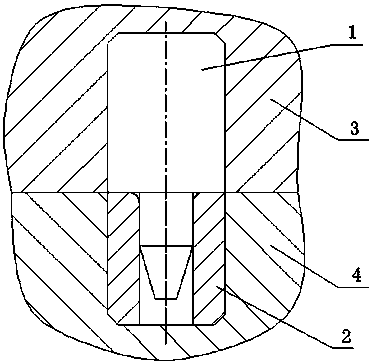

[0014] Such as figure 1 : The wooden mold positioning device for sand casting shown in the figure includes a convex side part and a concave side part. The convex side part is a steel positioning pin 1, and the concave side part is a steel positioning sleeve 2. The size of the steel positioning pin 1 The cylindrical surface matches the cylindrical surface of the inner hole of the steel positioning sleeve 2.

[0015] The small cylindrical surface of the steel positioning pin 1 is precisely matched with the inner cylindrical surface of the steel positioning sleeve 2 with a gap of 0.08±0.02mm to realize the positioning function.

[0016] The large cylindrical surface of the steel positioning pin 1 is knurled to prevent rotation during assembly and use. The upper end has chamfers, which play a guiding role during assembly; the lower end of the small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com