A method and device for fast refueling of chip mounter

A placement machine and tangent technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of inability to meet the needs of information management and refined management, lower production efficiency, and more manpower, to meet the requirements of information management and fine-grained The effect of optimizing management, improving refueling efficiency and production efficiency, and reducing waste of human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

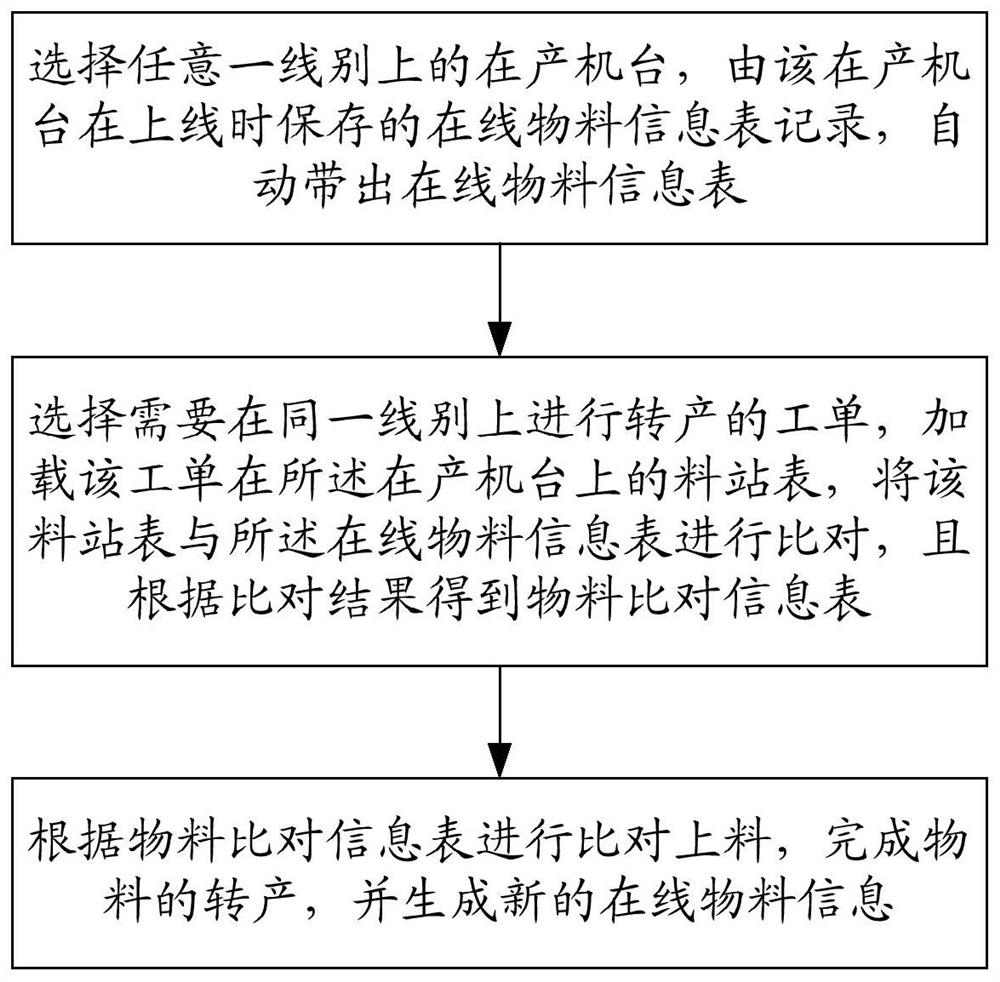

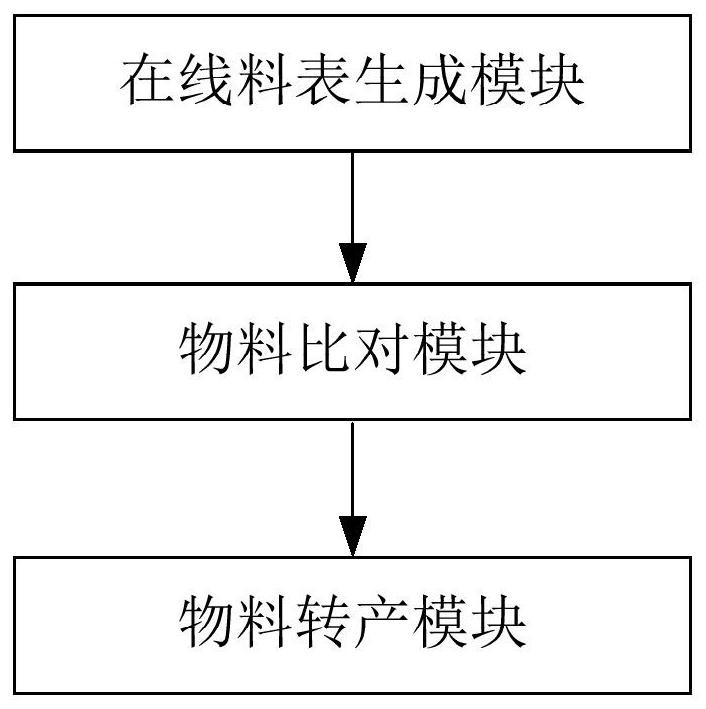

[0028] see figure 1 As shown, the present invention is a preferred embodiment of the tangential fast refueling method of a placement machine, and the method includes the following steps:

[0029] Step S1. Select an in-production machine on any line, and record it in the online material information table saved when the in-production machine goes online (each in-production machine will record the corresponding online material information when it goes online), and automatically Bring out the online material information table;

[0030] Step S2, select the work order that needs to be changed to production on the same line, load the material station table of the work order on the in-production machine, compare the material station table with the online material information table, and Obtain the material comparison information table according to the comparison result;

[0031] Step S3, compare and load materials according to the material comparison information table, complete the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com