Vacuum potting process

A potting and process technology, applied in the field of new energy vacuum potting technology, can solve the problems of low partial discharge initial voltage, ignition between lines, imbalance of resin and curing agent ratio, etc., to eliminate volume shrinkage internal stress, avoid Shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

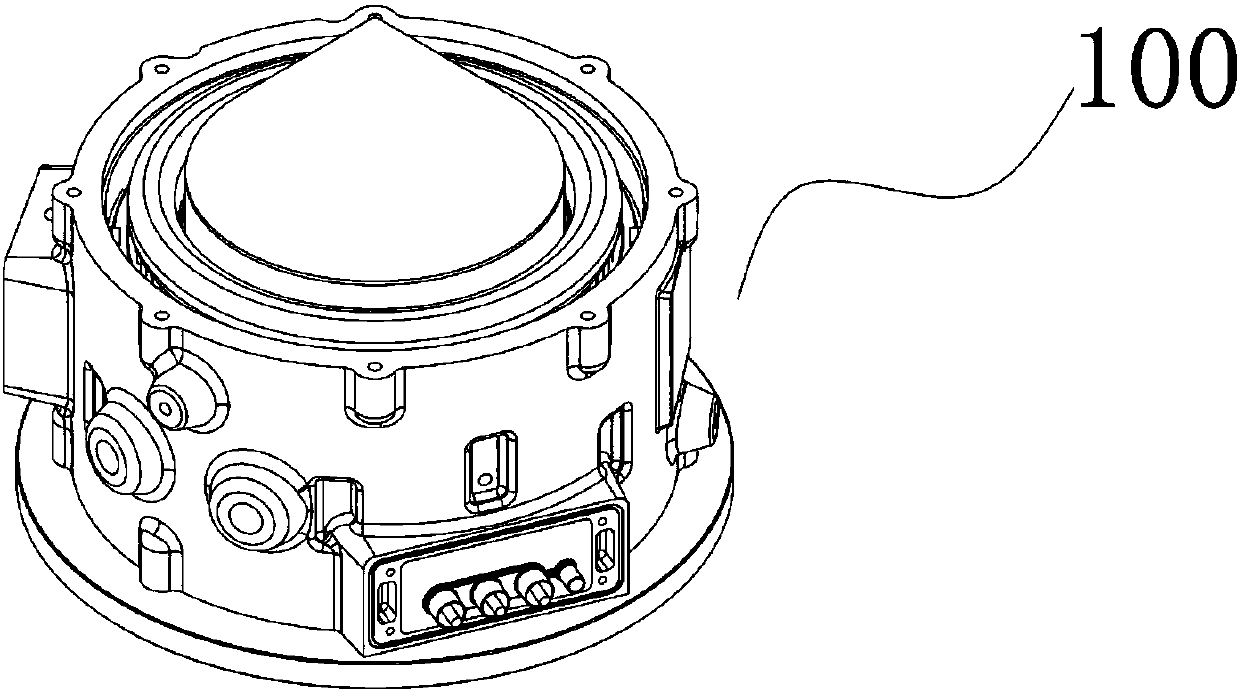

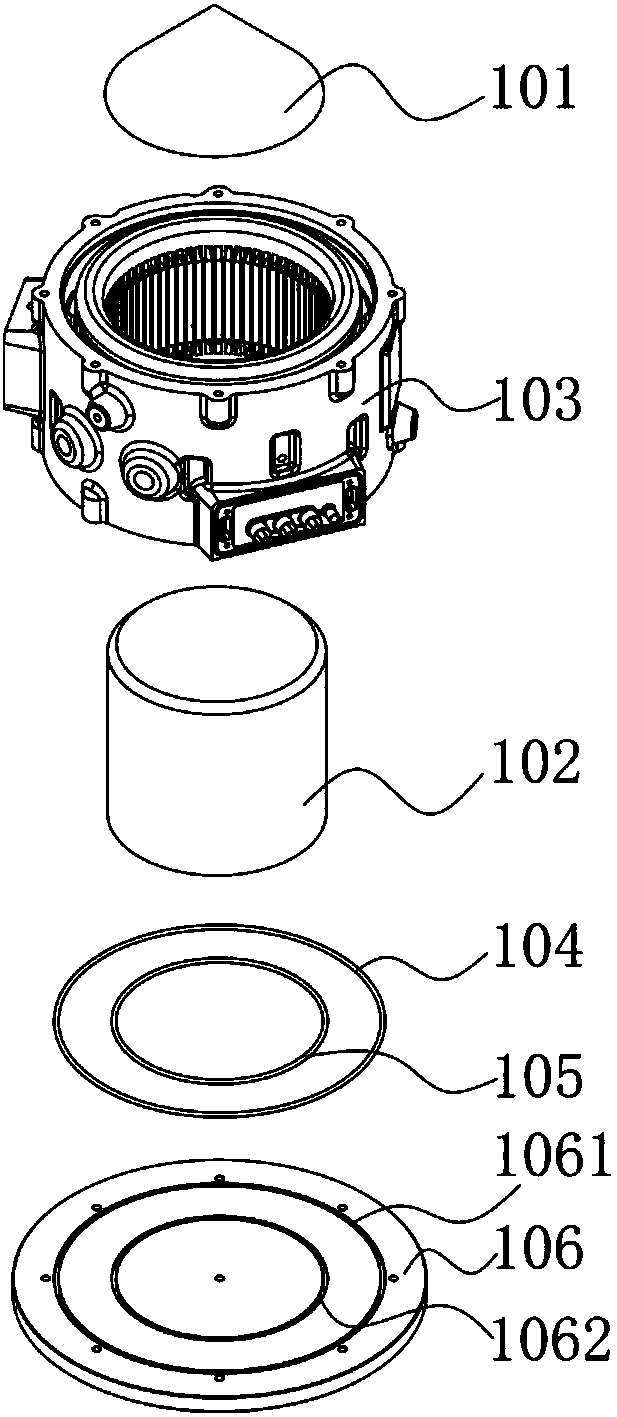

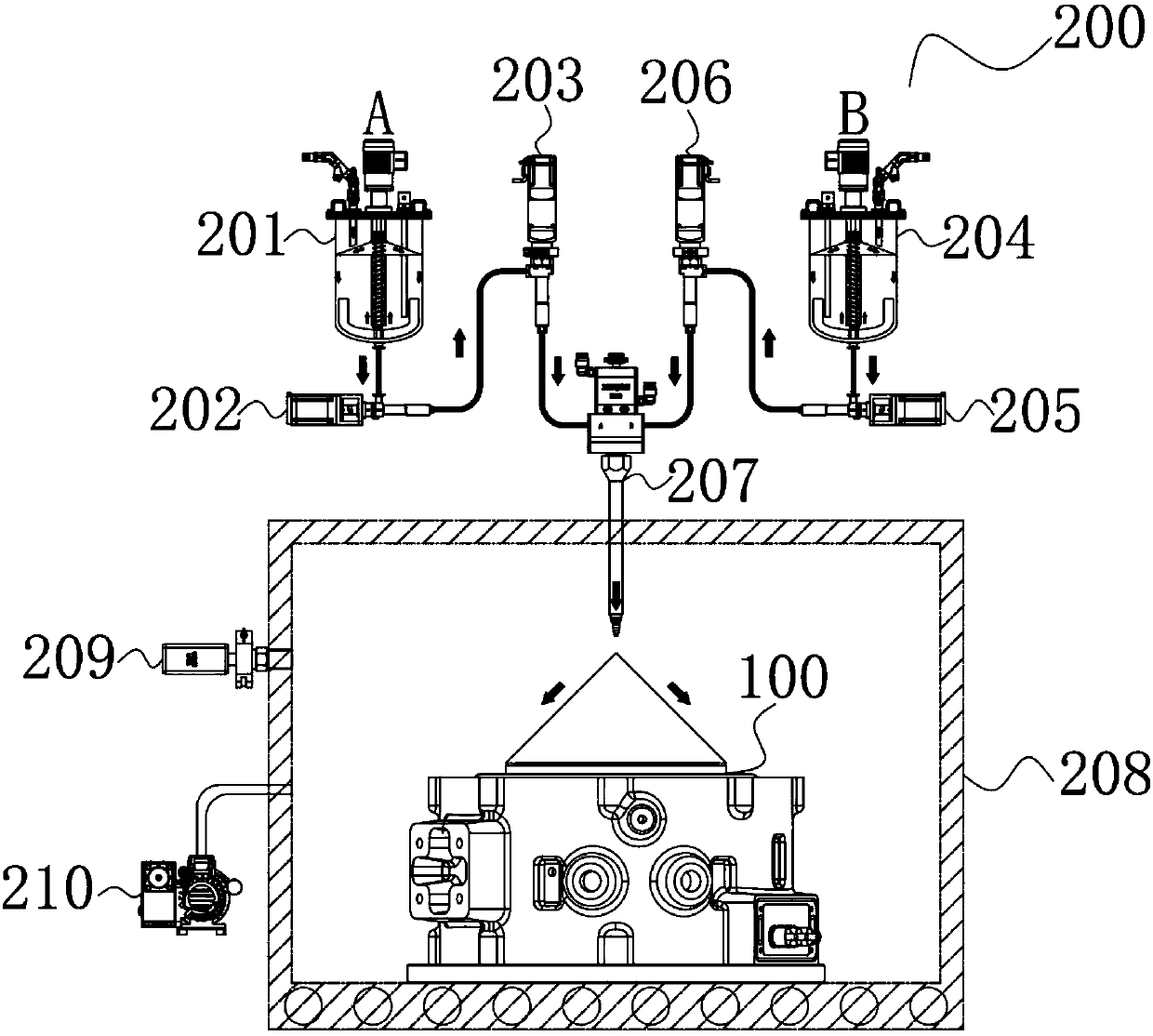

[0036] The invention provides a potting device for a stator of a new energy motor. refer to Figure 1 to Figure 3 , the potting device for the new energy motor stator includes a potting fixture 100 and a vacuum potting device 200, the potting fixture 100 is placed in the inner cavity of the vacuum potting device 200, and the potting fixture 100 includes a fixture guide umbrella 101, a fixture mandrel 102. The first sealing ring 104 of the fixture, the second sealing ring 105 of the fixture and the fixture base 106; the fixture base 106 is connected to the mandrel 102 of the fixture, and the second sealing ring 105 of the fixture is arranged on the second sealing groove 1062 of the fixture base 106, so that The fixture base 106 and the fixture mandrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com