A detector assembly dismantling process and its special dismantling equipment

A detector assembly and component technology, which is applied in nuclear engineering, reactor fuel elements, and greenhouse gas reduction, etc., can solve problems such as a large number of human radiation and excessive environmental doses, and achieve reasonable process design, good radiation protection, and shortened operation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

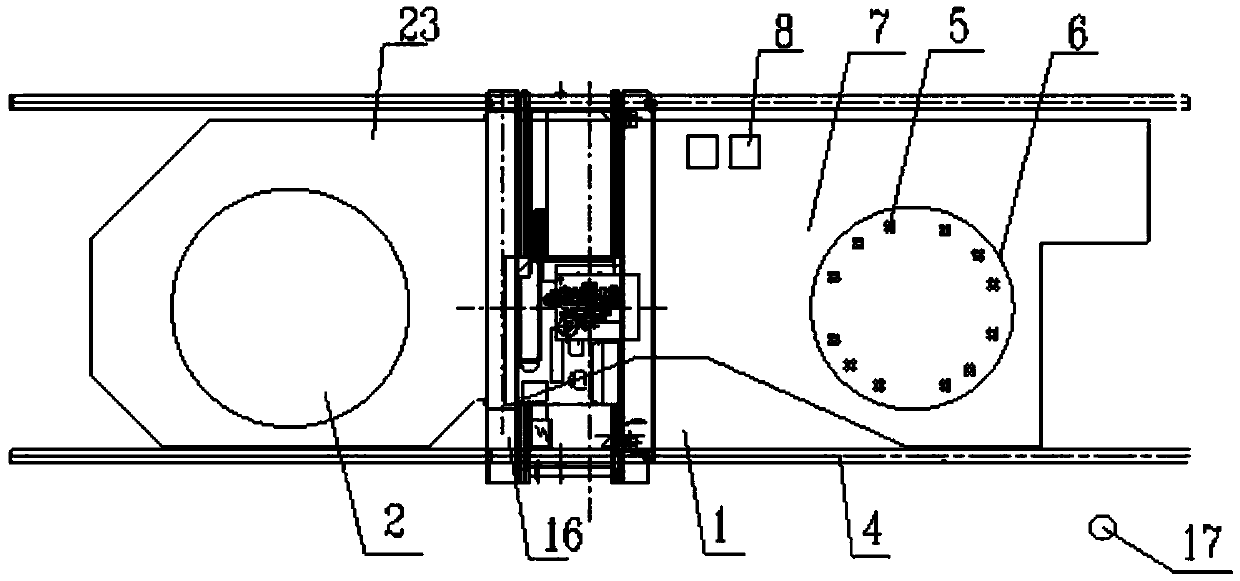

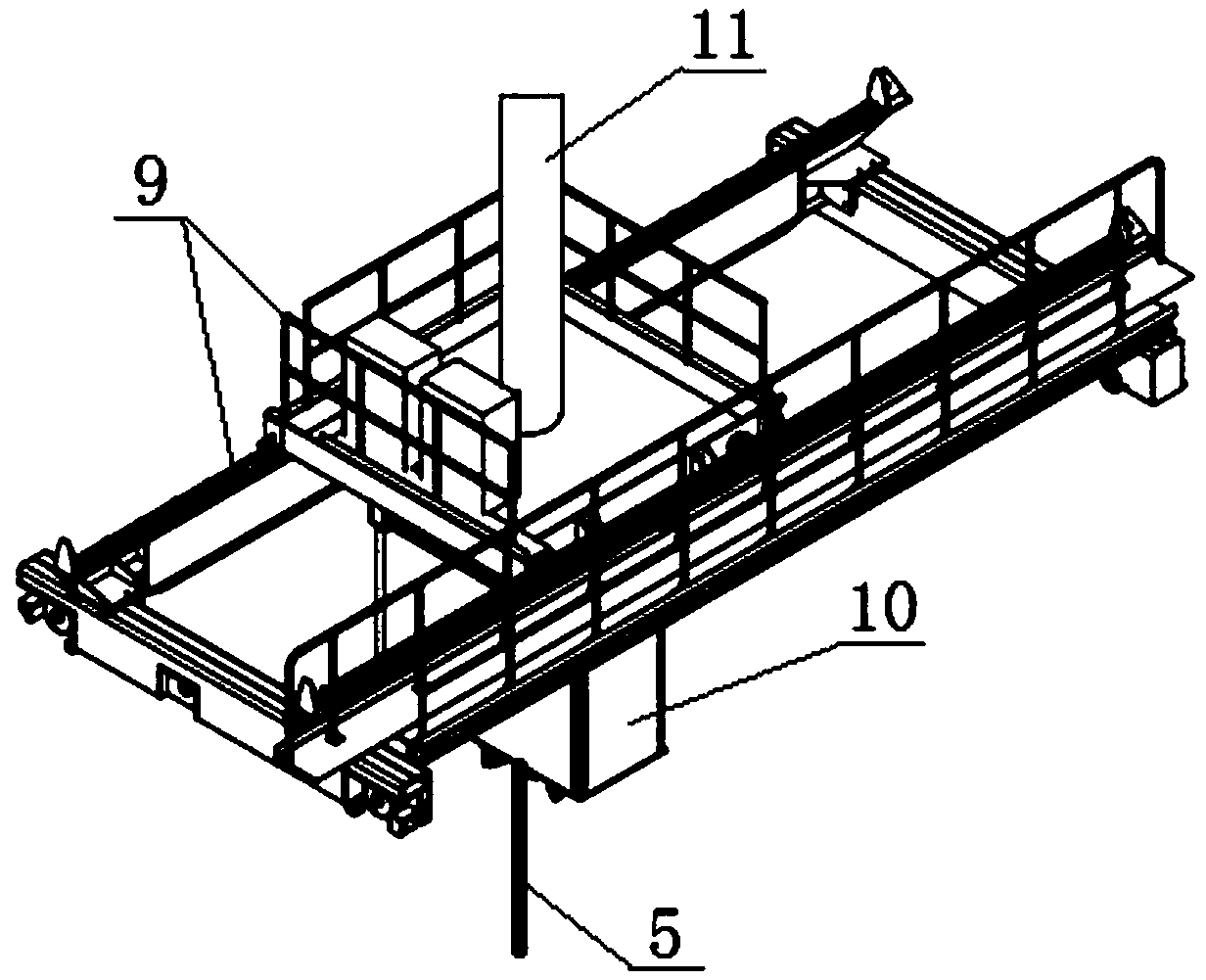

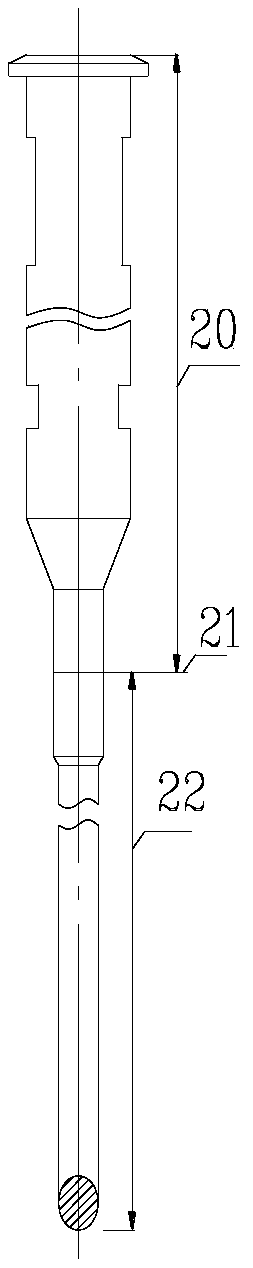

[0035] Such as Figure 1 to Figure 6 As shown, the present invention is the dismantling process and special dismantling equipment of the detector assembly introduced from the pressure vessel top cover during the non-full life of the nuclear power plant. During refueling, the detector assembly 5 to be dismantled is accompanied by the upper reactor internal 19 and the measurement guide structure 18 in the stack are stored in the refueling pool 7 together. There are 5 groups of four dismantled detector assemblies, a total of 12 groups are distributed on the outer edge of the upper internals 19. At this time:

[0036] —The internals hanger is disconnected from the upper internals 19, and transferred to the vacant position of the reactor building operation platform 1;

[0037] —The inner fuel assembly of the reactor pressure vessel assembly 2 has been shipped out to the spent fuel pool;

[0038] - After the loading and unloading machine 16 transfers the high-release container 8 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com