Vehicle-mounted laser PM2.5 sensor

A vehicle-mounted laser and sensor technology, used in scientific instruments, measuring devices, suspension and porous material analysis, etc., can solve the problems of inability to function as an induced draft fan, low detection accuracy, and unstable airflow, and achieve the measurement results. Accurate and reliable, accurate and reliable data, to ensure the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

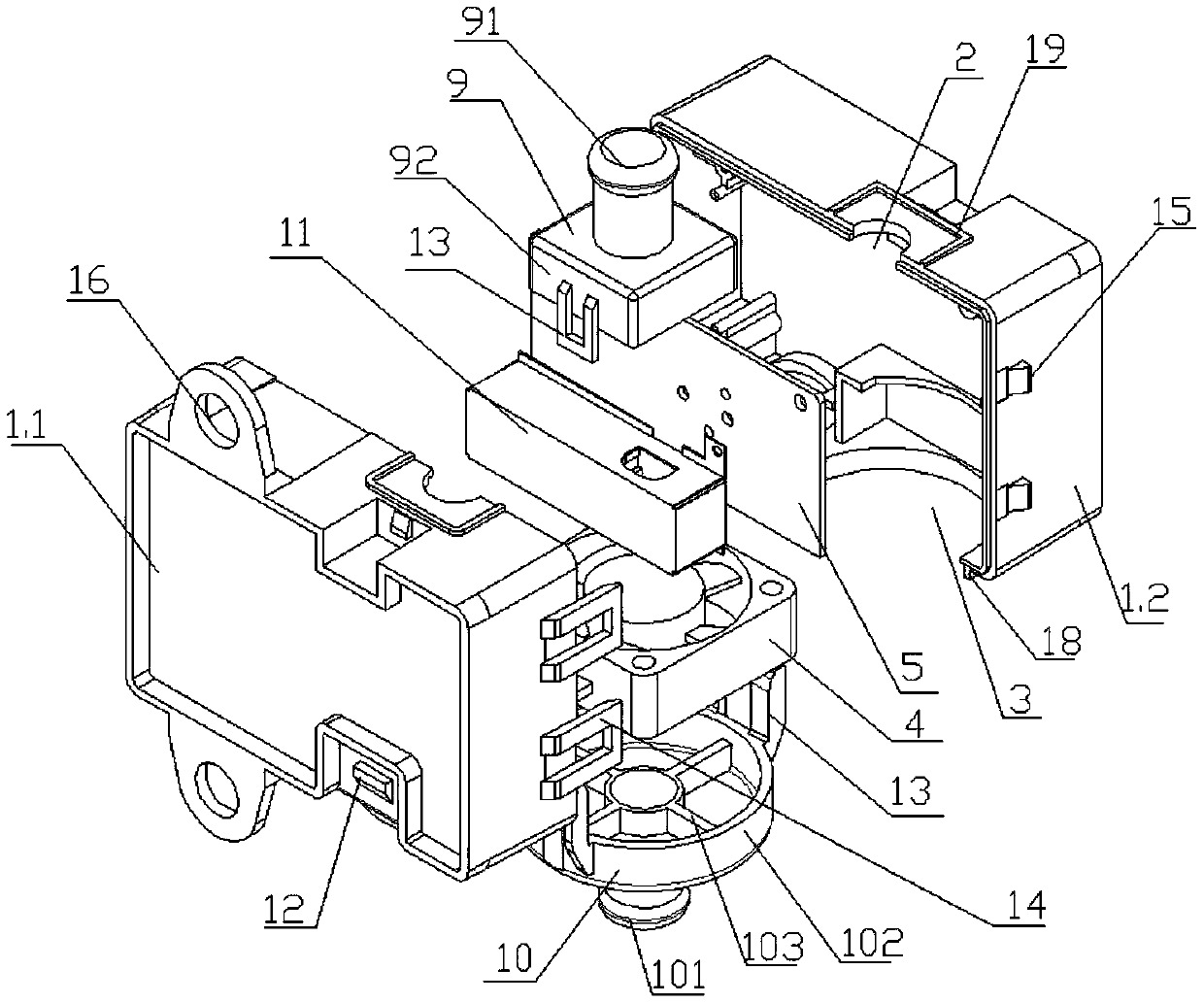

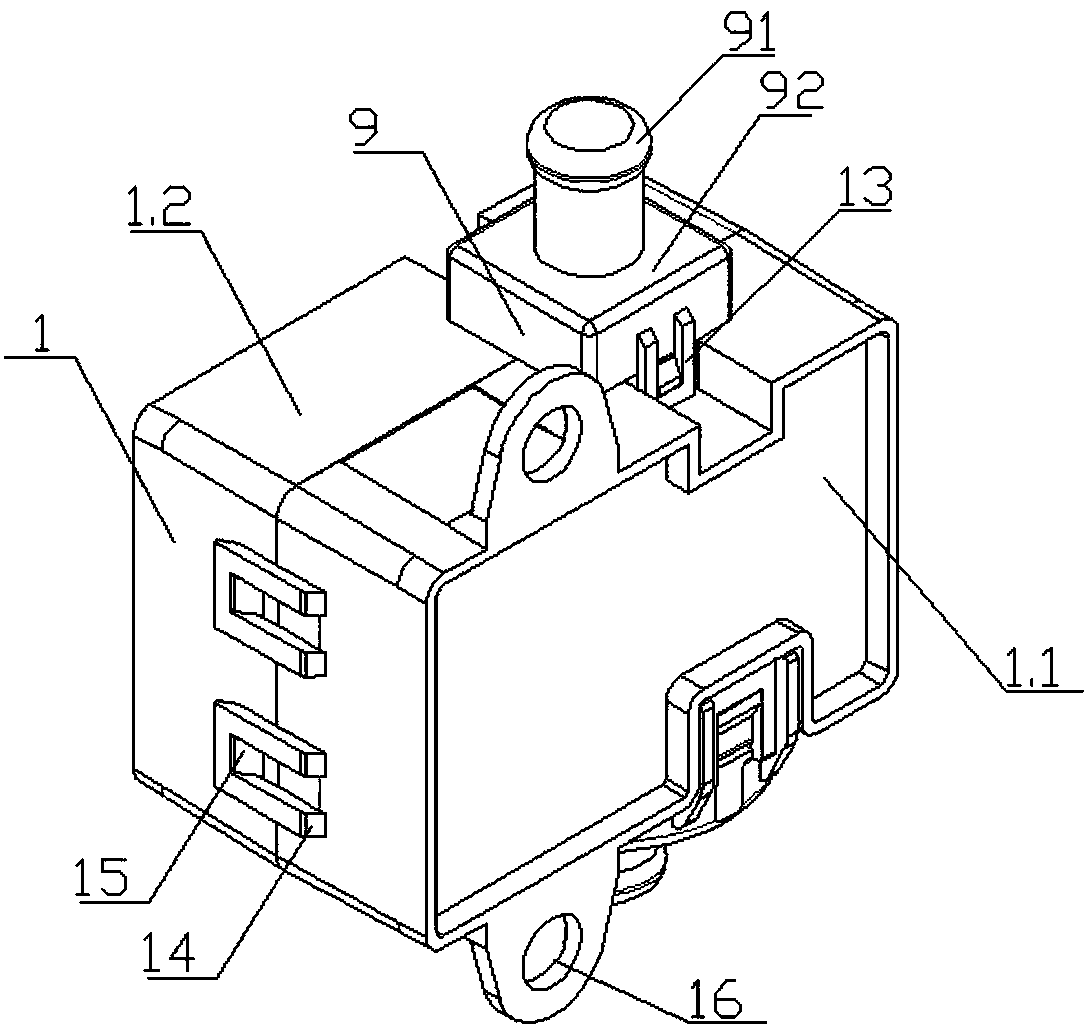

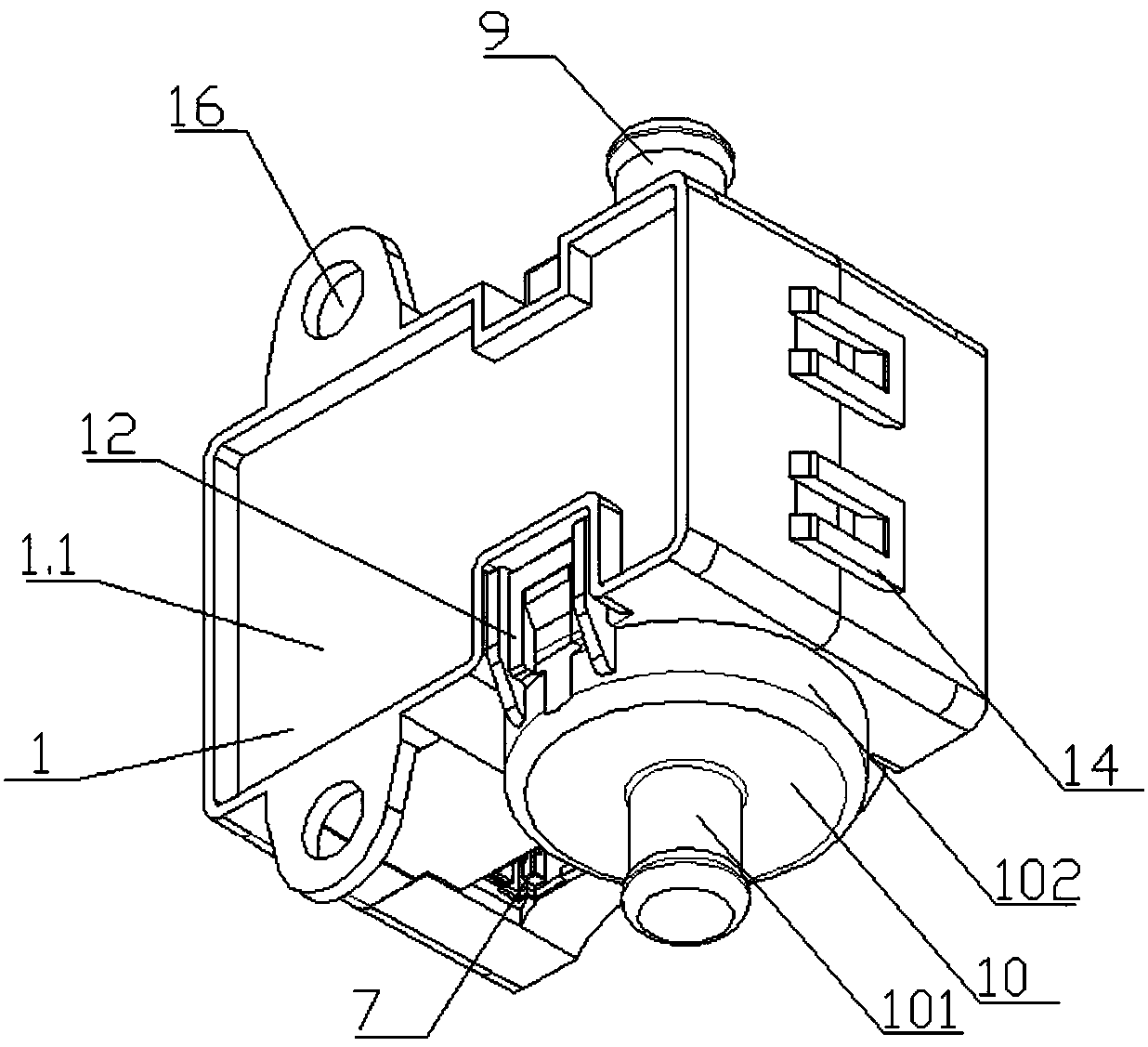

[0028] like Figure 1-5 As shown, a vehicle-mounted laser PM2.5 sensor includes a housing 1, and the housing 1 is provided with an air inlet 2 and an air outlet 3, and the air inlet 2 and the air outlet 3 are respectively located opposite to the housing 1. On the two side walls, an induced draft fan 4 is provided at the air outlet 3, a circuit board 5 is provided inside the housing 1, a connector terminal 7 is provided above the circuit board 5, and a laser module fixing seat is provided below the circuit board 5. The laser module fixing seat is provided with an air duct inlet, an air duct outlet, a photosensitive area, and a photodiode stop; The connection is an open square box structure 92, and the center of the opposite side of the opening of the square box structure 92 is connected with an air induction pipe joint 91; The connection between 10 and the air outlet 3 is a disc structure 102, the disc structure 102 and the air outlet 3 are adapted to the air guide port of the...

Embodiment 2

[0034] This embodiment is a further optimization of Embodiment 1. The edge of the air outlet 3 is provided with a limiting convex ring 18, and the bottom edge of the exhaust port 10 is a circular ring. match the diameter. When in use, the air exhaust interface 10 is directly buckled on the limiting convex ring 18 to prevent the air exhaust interface 10 from moving relative to the air outlet 3 .

[0035] As a preferred implementation of this embodiment, the air inlet 2 is provided with a square protrusion 19 , and the size of the square box structure 92 matches the size of the square protrusion 19 . When in use, the square box structure 92 is fastened on the square protrusion 19 to prevent the relative movement of the air introduction interface 9 .

[0036] As a preferred implementation of this embodiment, a shielding cover 11 is arranged below the circuit board 5, and the laser module fixing seat is arranged inside the shielding cover 11 for shielding the electromagnetic inte...

Embodiment 3

[0042] The difference between this embodiment and the above embodiments is that: the diameter of the disc structure 102, the opening side length of the square box structure 92, and the aperture ratio of the exhaust pipe joint 101 are 7:5:2.

[0043] The inventor also carried out the simulated vehicle-mounted dust concentration detection test as in Example 1 by using the sensor in Example 1, and recorded the comparison test results between the PM2.5 value detected by each group of sensors and the standard value under different external disturbance conditions. The wind speed impact test results are as follows:

[0044]

[0045] Through the comparison of the detection results of each sensor in the above-mentioned wind speed impact test, it is found that the error between the PM2.5 value detected by each group of sensors and the standard value is ±8.0μg / m 3 within range. It shows that the detection result of the sensor in the embodiment of the present invention is not much dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com