Mechanical continuously variable transmission method involving dual planetary mechanism and continuously variable transmission mechanism

A stepless speed change mechanism and stepless speed change technology, applied in mechanical equipment, gear transmission, belt/chain/gear and other directions, can solve the problems of high manufacturing cost and high noise, and achieve low cost, high efficiency and strong durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

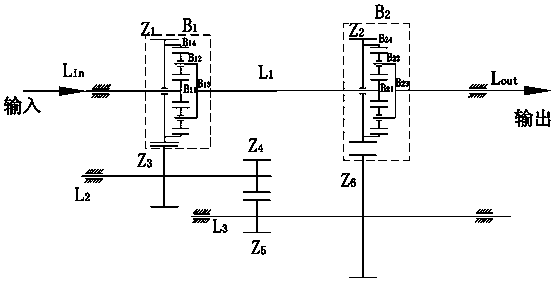

[0048] Such as figure 1 As shown, a continuously variable transmission mechanism made according to the mechanical continuously variable transmission method composed of double planetary mechanisms, including the first planetary group B 1 and the second planetary group B 2 , the first planetary group B 1 with the second planetary group B 2 series, the first planetary group B 1 Built-in first sun gear B 11 , the first planetary carrier B 13 , the first sun gear B 11 with the first planetary carrier B 13 Via the two first planetary gears B 12 connection, second planetary group B 2 Built-in second sun gear B 21 , the second planetary carrier B 23 , the second sun gear B 21 with the second planetary carrier B 23 Via the two second planetary gears B 22 Connection, 1st sun gear B 21 Installed on the input shaft L in On, the first planetary carrier B 13 with the second sun gear B 21 through the first axis L 1 Joint, second planet carrier B 23 Installed on the output...

Embodiment 2

[0052] Such as figure 2 As shown, a continuously variable transmission mechanism made according to the mechanical continuously variable transmission method composed of double planetary mechanisms, including the first planetary group B 1 and the second planetary group B 2 , the first planetary group B 1 with the second planetary group B 2 series, the first planetary group B 1 Built-in first sun gear B 11 , the first planetary carrier B 13 , the first sun gear B 11 with the first planetary carrier B 13 Via the two first planetary gears B 12 connection, second planetary group B 2 Built-in second sun gear B 21 , the second planetary carrier B 23 , the second sun gear B 21 with the second planetary carrier B 23 Via the two second planetary gears B 22 Connection, 1st sun gear B 21 Installed on the input shaft L in On, the first planetary carrier B 13 with the second sun gear B 21 Connected by chain CH, the second planetary carrier B 23 Installed on the output shaf...

Embodiment 3

[0056] Such as image 3 As shown, a continuously variable transmission mechanism made according to the mechanical continuously variable transmission method composed of double planetary mechanisms, including the first planetary group B 1 and the second planetary group B 2 , the first planetary group B 1 with the second planetary group B 2 series, the first planetary group B 1 Built-in first sun gear B 11 , the first planetary carrier B 13 , the first sun gear B 11 with the first planetary carrier B 13 Via the two first planetary gears B 12 connection, second planetary group B 2 Built-in second sun gear B 21 , the second planetary carrier B 23 , the second sun gear B 21 with the second planetary carrier B 23 Via the two second planetary gears B 22 connection, the first planetary group B 1 Also includes the first ring gear B 14 , the first ring gear B 14 with two first planetary gears B 12 meshing, first ring gear B 14 The first gear Z is installed on the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com