Gas expanding agent for cementing medium-temperature and high-temperature wells and application thereof

A gas expansion, medium and high temperature technology, which is applied to drilling compositions, chemical instruments and methods, etc., can solve the problems of excessively fast gas generation rate, application limitation, and insufficient expansion rate of expansion agents, and improve the ability to prevent gas channeling. , The effect of improving the cementation quality and compensating for the pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

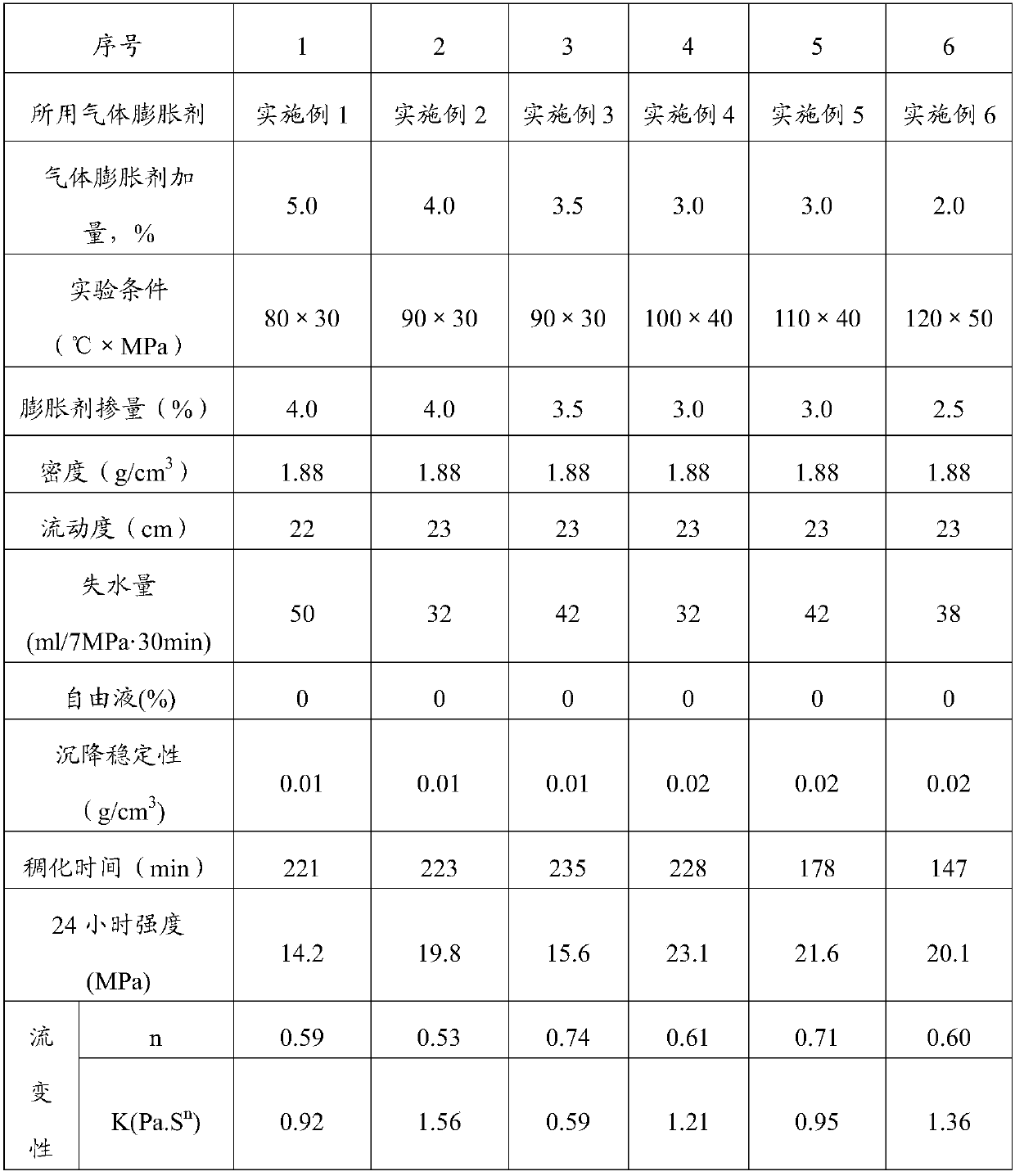

Embodiment 1

[0040] This embodiment provides an oil well cement gas expansion agent suitable for medium and high temperature well cementing at 80°C to 120°C. The gas expansion agent specifically includes:

[0041] 20 parts by weight of 4,4'-oxobisbenzenesulfonyl hydrazide, the azodicarbonamide of 10 parts by weight;

[0042] 6 parts by weight of urea, 4 parts by weight of zinc oxide;

[0043] 20 parts by weight of micro-silicon, 50 parts by weight of calcium carbonate;

[0044] The tea saponin of 0.5 weight part.

[0045] According to the above proportions, each component was mixed in a dry mixing device for ten minutes to obtain the gas expansion agent of this embodiment.

Embodiment 2

[0047] This embodiment provides an oil well cement gas expansion agent suitable for medium and high temperature well cementing at 80°C to 120°C. The gas expansion agent specifically includes:

[0048] 20 parts by weight of p-toluenesulfonyl hydrazide, 10 parts by weight of azodicarbonamide;

[0049] The urea of 5 parts by weight, the lead oxide of 5 parts by weight;

[0050] The bentonite of 20 parts by weight, the calcium carbonate of 50 parts by weight;

[0051] 0.5 parts by weight of sodium α-alkenyl sulfonate.

[0052] According to the above proportions, each component was mixed in a dry mixing device for ten minutes to obtain the gas expansion agent of this embodiment.

Embodiment 3

[0054] This embodiment provides an oil well cement gas expansion agent suitable for medium and high temperature well cementing at 80°C to 120°C. The gas expansion agent specifically includes:

[0055] 15 parts by weight of p-toluenesulfonyl hydrazide, 15 parts by weight of N, N'-dinitrosopentamethylenetetramine;

[0056] The zinc oxide of 5 parts by weight, the sodium benzoate of 5 parts by weight;

[0057] The bentonite of 30 parts by weight, the calcium carbonate of 40 parts by weight;

[0058] 0.5 parts by weight of sodium α-alkenyl sulfonate.

[0059] According to the above proportions, each component was mixed in a dry mixing device for ten minutes to obtain the gas expansion agent of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com