Flexible lightweight shape-stabilized phase change energy storage piece and preparation method thereof

A technology of phase-change energy storage and phase-change energy storage materials, which is applied in the field of phase-change energy storage sheets, can solve the problems of high shell density, no flexibility, and uneven distribution of phase-change energy storage sheets, so as to reduce thermal resistance and ensure Size, impact mitigation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations and examples.

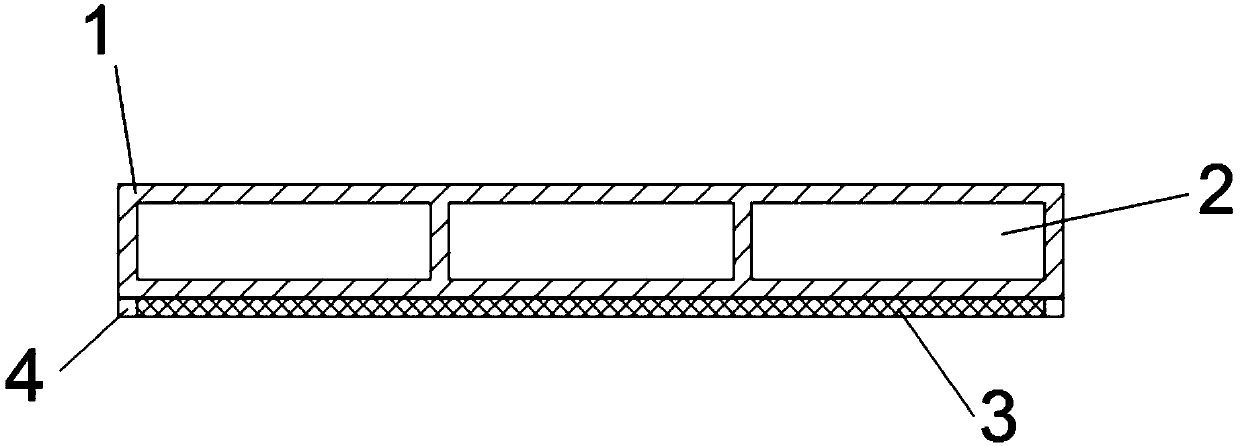

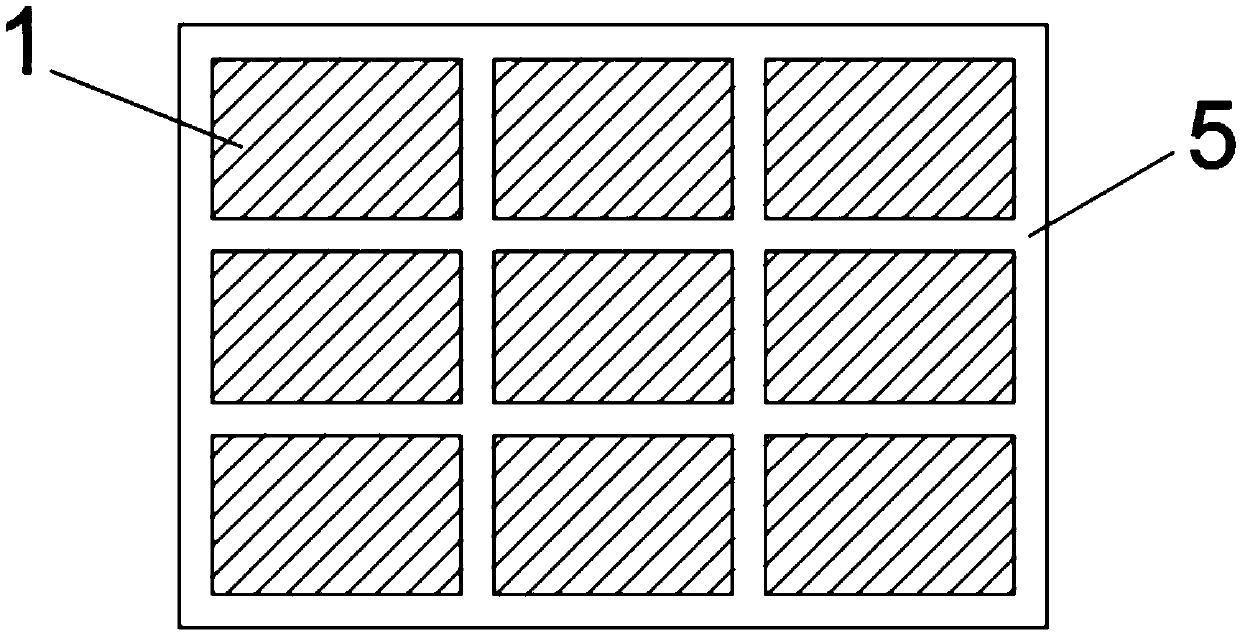

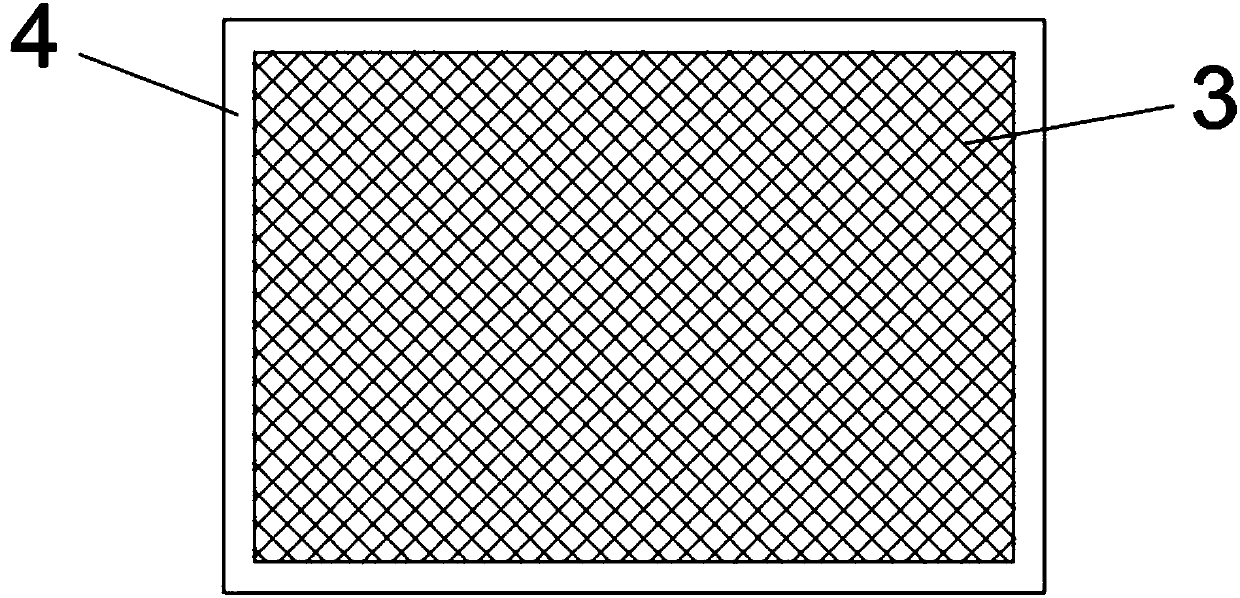

[0041] see figure 1 , figure 2 and image 3 , a flexible and lightweight shaped phase-change energy storage chip, including an array shaped body, a thermally conductive phase-change energy storage material is packaged in the array shaped body, the bottom surface of the array shaped body is pasted with fixing glue, and the middle position is pasted with a heat-conducting gap filler Material;

[0042] The array shaped body is made of a micro-sealed bag, and the micro-sealed bag is a plastic bag or an aluminum foil bag.

[0043] A flexible and lightweight shaped phase-change energy storage sheet, comprising the following components in parts by weight: 1-10 parts of an array shaped body, 10-90 parts of a heat-conducting phase-change en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com