Crystallization of polymyxin sulfate b1, b2 or mixture thereof and preparation method thereof

A polymyxin sulfate and crystallization technology, which is applied to the crystallization of polymyxin sulfate B1, B2 or their mixtures and the field of their preparation, can solve the problem that the products are easy to stick to form agglomerates, affect the quality and curative effect of drugs, production and research. Inconvenience and other problems, to achieve the effect of improving drug quality and loosening crystal particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

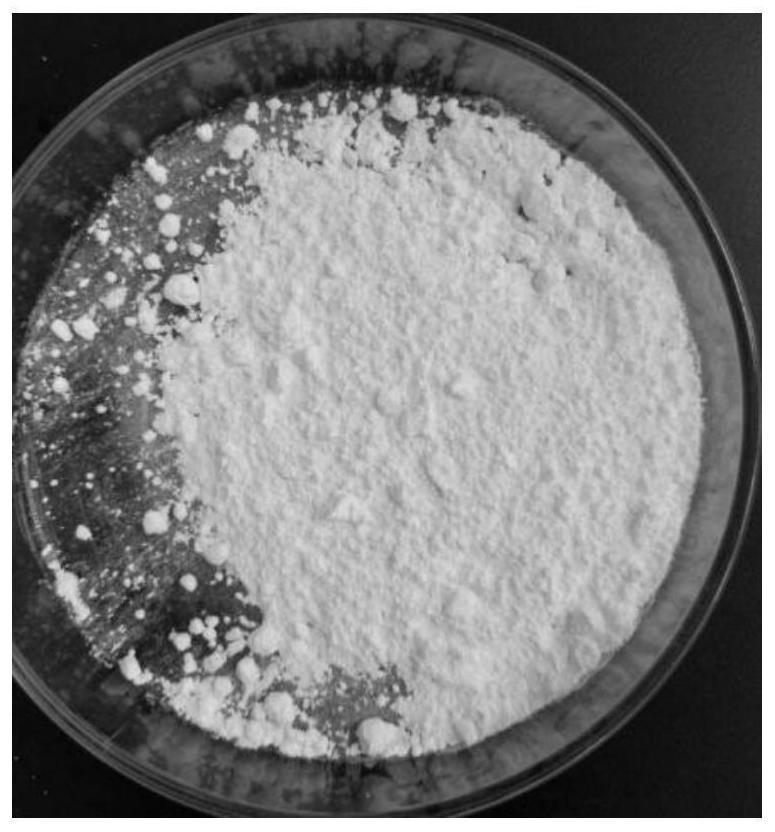

[0066] Ethanol-water system: Take 100ml of polymyxin B1 sulfate aqueous solution with a concentration of 50g / L, stir at room temperature, add 3 times the volume of 95% (v / v) ethanol aqueous solution, and polymyxin B1 sulfate crystallizes out. After stirring at a temperature of 0-5° C. for 3-5 hours, filter, and vacuum-dry for 8 hours to obtain crystalline polymyxin sulfate B1, the crystal form is crystal form A.

Embodiment 2

[0068] Isopropanol-water: Take 26ml of polymyxin sulfate B1 and B2 aqueous solutions with a concentration of 50g / L, and slowly add it dropwise to 260ml (10 times the volume) of isopropanol under stirring. The temperature of isopropanol is always Control at 5-10°C. The crystals of polymyxin sulfate B1 and B2 precipitated during the dropwise addition gradually increased and were in a state of uniform dispersion without adhesion. Stirring was continued for 1 hour, the solid was obtained by filtration, and vacuum-dried for 10 hours to obtain 1.23 g of polymyxin sulfate B1 and B2 crystalline powders with a crystallization yield of 94.6%, wherein the crystal form of polymyxin sulfate B1 was crystal form 1.

Embodiment 3

[0070] n-Butanol-Water: Take 13.5g of polymyxin B2 sulfate, dissolve it in 150ml of pure water, and slowly add it dropwise to 1500ml (10 times the volume) of n-butanol in a stirring state, the temperature is always controlled at 25-30°C. During the dropping process, the precipitated polymyxin B2 sulfate gradually increased, and it was in a state of uniform dispersion, no adhesion, and good granularity. After the polymyxin B2 sulfate aqueous solution was added dropwise, the stirring was continued for 30 min, filtered, and vacuum-dried for 20 hours to obtain 13.2 g of polymyxin B2 sulfate crystalline powder with a crystallization yield of 97.8%.

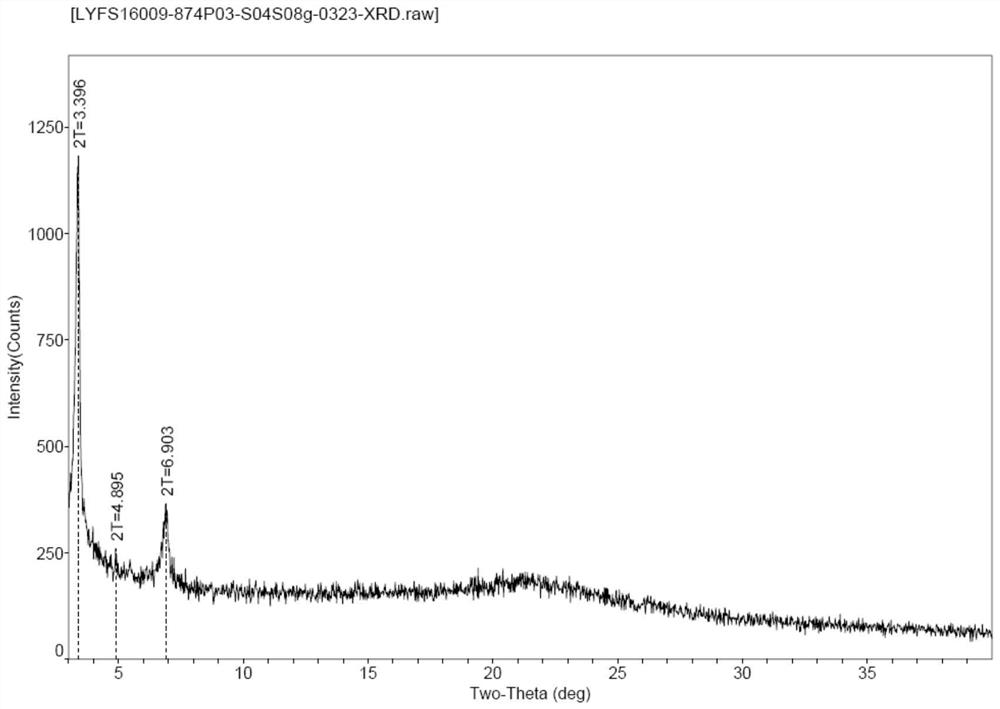

[0071] From the XRD patterns of polymyxin B2 sulfate and polymyxin B1 sulfate, it can be seen that in the XRD pattern of polymyxin B2 sulfate, there is a weak small peak at 2θ=31.8°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com