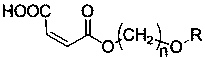

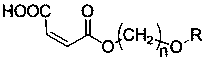

Maleate monomers used for preparing pour depressant components

A technology of maleic acid esters and pour point depressants, which is applied in the field of structure design and preparation of maleic acid esters, can solve the problems of high price and rare alcohol, and achieve the effects of various types, simple preparation methods, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

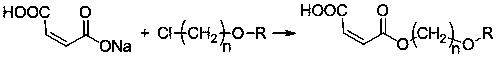

Method used

Image

Examples

Embodiment 1

[0021] The preparation of mono-(4-hexadecyloxy)-butyl maleate comprises the following steps;

[0022] (1) Add 121.2g (0.5mol) of n-hexadecanol, 24.0g (0.6mol) of sodium hydroxide powder, and 650mL of dimethyl sulfoxide into a 1000mL four-necked bottle in turn, stir to make the dispersion well, and then slowly heat to 83°C , to obtain a light yellow clear sodium alkoxide solution, which was cooled to 50°C for later use.

[0023] Add 76.2g (0.6mol) 1,4-dichlorobutane and 200mL dimethyl sulfoxide into a 2000mL four-neck flask, heat to 45°C under stirring, slowly add the above sodium alkoxide solution from the insulating funnel, and keep The temperature is 40-45°C, drop it for 3 hours, then keep it warm and stir for 3.5 hours, then slowly add 800mL water at 60°C under stirring, separate the oil layer while it is hot, wash with hot water at 60°C, and get a viscous oil. 89.3%

[0024] (2) Add 133.2g (0.4mol) of the above-mentioned chlorinated ether, 47.0 (0.5mol)g sodium maleate a...

Embodiment 2

[0026] The preparation of mono-(4-octadecyloxy)-butyl maleate comprises the following steps;

[0027] (1) Add 135.2g (0.5mol) n-octadecyl alcohol, 24.0g (0.6mol) sodium hydroxide powder, and 650mL dimethyl sulfoxide to a 1000mL four-necked bottle in turn, stir to make the dispersion well, and then slowly heat to 83°C , to obtain a light yellow clear sodium alkoxide solution, which was cooled to 50°C for later use.

[0028] Add 76.2g (0.6mol) 1,4-dichlorobutane and 200mL dimethyl sulfoxide into a 2000mL four-neck flask, heat to 45°C under stirring, slowly add the above sodium alkoxide solution from the insulating funnel, and keep The temperature is 40~45°C, after 3 hours of dripping, then keep stirring for 3.5 hours, then slowly add 800mL of water at 60°C under stirring, separate the oil layer while it is hot, wash with hot water at 60°C, and obtain a viscous oil. 86.8%

[0029] (2) Add 144.4g (0.4mol) of the above-mentioned chlorinated ether, 47.0 (0.5mol)g sodium maleate an...

Embodiment 3

[0031] The preparation of mono-(6-octadecyloxy)-hexyl maleate comprises the following steps;

[0032] (1) Add 135.2g (0.5mol) n-octadecyl alcohol, 24.0g (0.6mol) sodium hydroxide powder, and 650mL dimethyl sulfoxide to a 1000mL four-necked bottle in turn, stir to make the dispersion well, and then slowly heat to 83°C , to obtain a light yellow and clear sodium alkoxide solution, which was cooled to 50°C for later use;

[0033] Add 93.0g (0.6mol) 1,6-dichloro-n-hexane and 200mL dimethyl sulfoxide into a 2000mL four-neck flask, heat to 45°C under stirring, slowly add the above sodium alkoxide solution from the insulating funnel, and keep The temperature is 40~45°C, after 3 hours of dripping, then keep stirring for 3.5 hours, then slowly add 800mL of water at 60°C under stirring, separate the oil layer while it is hot, wash with hot water at 60°C, and obtain a viscous oil. 74.8%.

[0034] (2) Add 155.6g (0.4mol) of the above-mentioned chlorinated ether, 47.0 (0.5mol)g sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com