High-mesopore-amount Y type zeolite and preparation method thereof

A high mesoporous, zeolite technology, applied in the direction of crystalline aluminosilicate zeolite, faujahedral crystalline aluminosilicate zeolite, etc., can solve the problems of loss of Y-type zeolite acid content, not many applications, etc., and achieves moderate experimental conditions and preparation. Simple, low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a Y-type zeolite with high mesoporous content, which is prepared through the following steps:

[0038]100g of small-grained NaY zeolite (grain size 200-300nm) with a skeleton silicon-aluminum ratio of 4.8 was exchanged with 100g of ammonium chloride and 1000g of water at 90°C for 1 hour for ammonium ion exchange, then fully washed, dried overnight at 120°C, and after drying The sample was raised to 500°C at a rate of 4°C / min in a muffle furnace, and kept for 4h for roasting treatment; after that, the same ammonium ion exchange as above was performed to obtain a small-grained NH with an exchange degree of more than 80%. 4 Y zeolite.

[0039] Stir and dissolve 8.58g of ammonium oxalate and 200g of water in a 65°C water bath to prepare a buffer solution with a concentration of 0.3M; 4 Add the Y zeolite to the prepared ammonium oxalate buffer solution and beat at 65°C to obtain a slurry.

[0040] Stir and dissolve 4.25g ammonium fluorosilicate and...

Embodiment 2

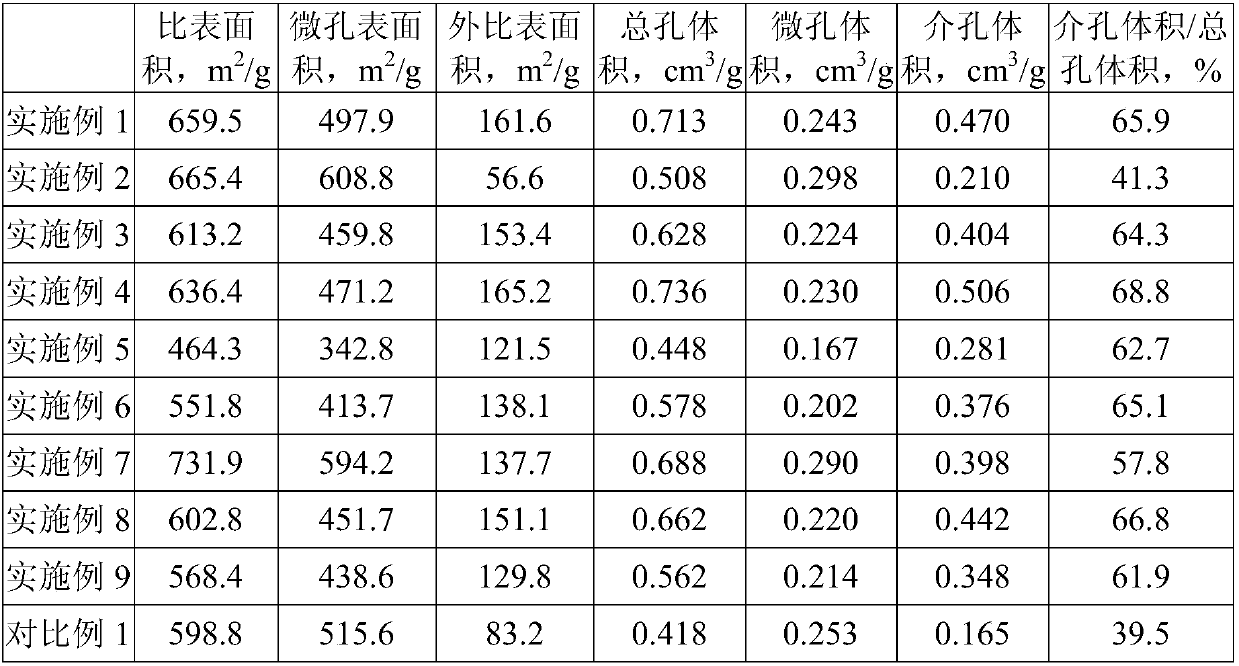

[0045] The method described in Example 1 was used to prepare Y-type zeolite with high mesoporous volume and small crystal grains, except that the dealumination and silicon supplementation step was only performed once, and the relevant test and characterization results are shown in Table 1.

Embodiment 3

[0047] The method described in Example 1 was used to prepare Y-type zeolite with high mesoporous content and small crystal grains, except that the silicon-alumina ratio of the initial small grain NaY zeolite was 4.2, and the relevant test and characterization results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com