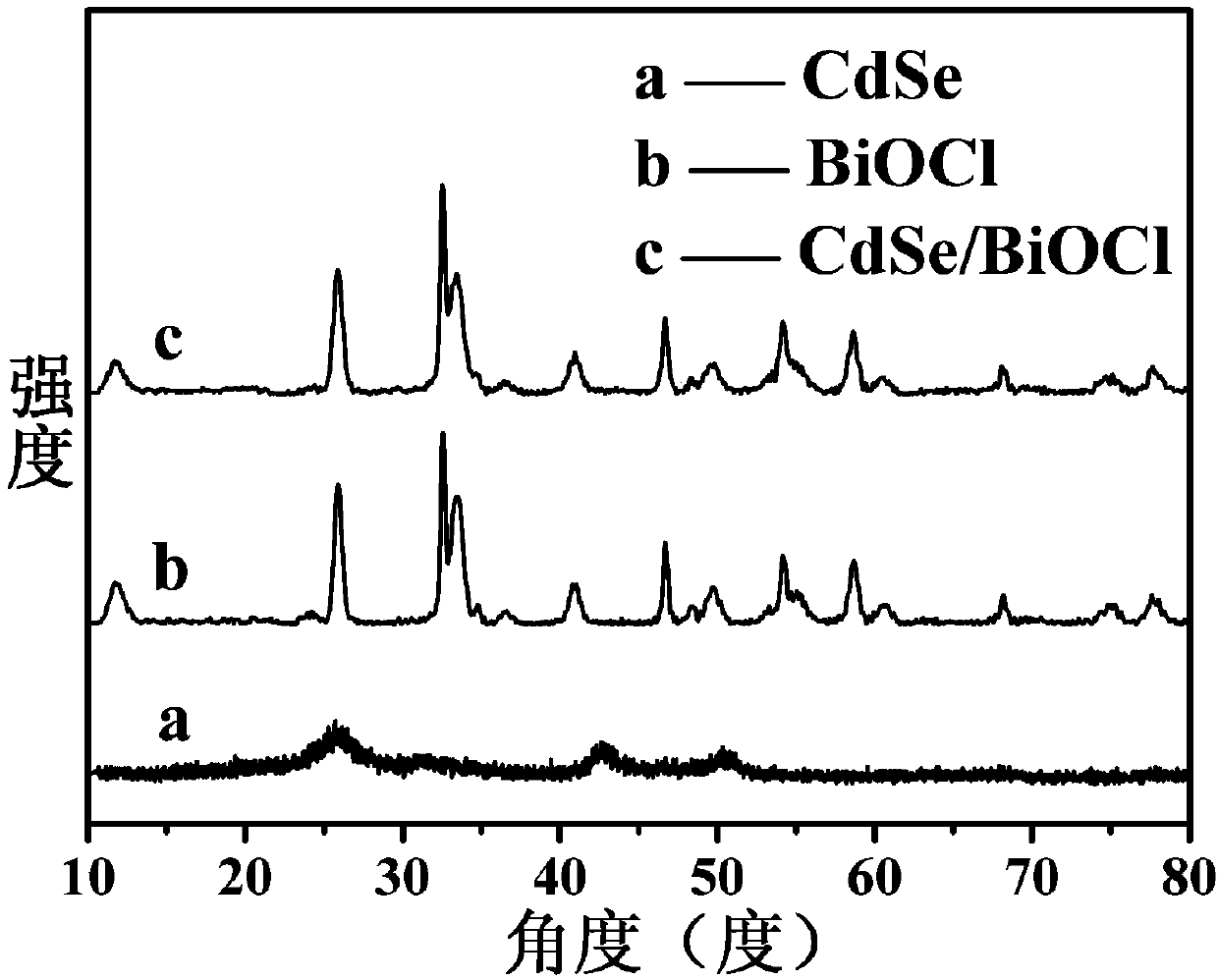

Preparation and application of CdSe/BiOCl-based composite photocatalyst

A photocatalyst and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as limiting the effective development of photocatalytic performance, and achieve uniform size, separation, and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

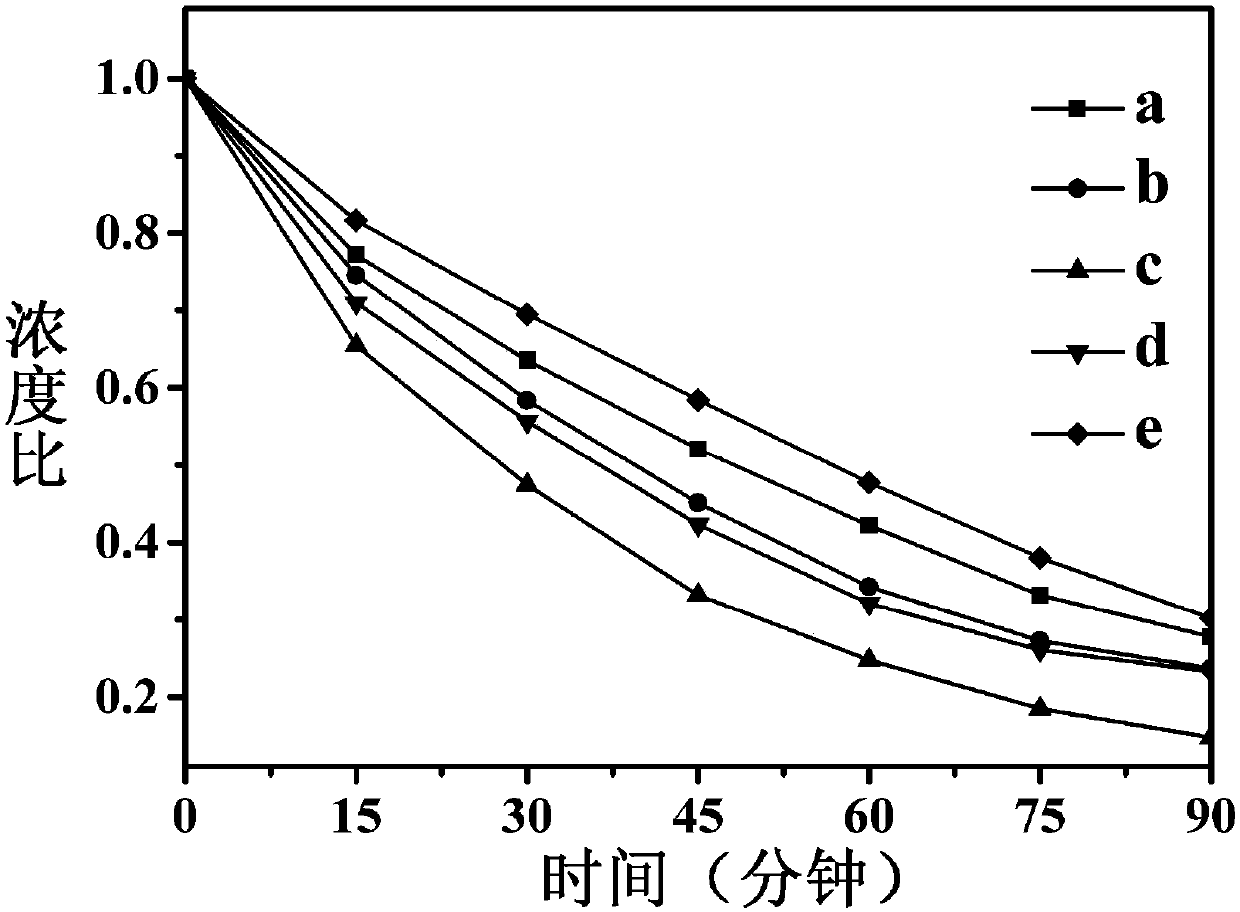

Embodiment 1

[0035] (1) Preparation of CdSe quantum dots: first weigh 0.4567g cadmium chloride (CdCl 2 2.5H 2 O) put into the there-necked flask, add 200mL deionized water to dissolve fully, and keep logical N 2 After half an hour, 0.341 mL of stabilizer methacrylic acid was added, and after thorough stirring, the pH of the solution was adjusted to 7 with 1 mol / L sodium hydroxide solution. Simultaneously weigh 0.1579g of selenium powder (Se) and 0.75g of sodium borohydride (NaBH 4 ) into a 10mL small beaker, add 7mL deionized water to dissolve completely, and pass N 2 Protect against oxidation, wait until the white precipitate appears and the precipitation is complete, use the dropper to absorb the supernatant liquid, drop by drop into the above three-necked flask solution, and react in a water bath at 80°C for 4 hours, take out the flask to cool naturally, centrifuge the solution, wash with water and alcohol CdSe quantum dots can be obtained after drying in an oven at 60° C. for 6 hour...

Embodiment 2

[0041] (1) Preparation of CdSe quantum dots: first weigh 0.4567g cadmium chloride (CdCl 2 2.5H 2 O) put into the there-necked flask, add 200mL deionized water to dissolve fully, and keep logical N 2 After half an hour, 0.341 mL of stabilizer methacrylic acid was added, and after thorough stirring, the pH of the solution was adjusted to 7 with 1 mol / L sodium hydroxide solution. Simultaneously weigh 0.2369g of selenium powder (Se) and 0.75g of sodium borohydride (NaBH 4 ) into a 10mL small beaker, add 7mL deionized water to dissolve completely, and pass N 2 Protect against oxidation, wait until the white precipitate appears and the precipitation is complete, use the dropper to absorb the supernatant liquid, drop by drop into the above three-necked flask solution, and react in a water bath at 80°C for 4 hours, take out the flask to cool naturally, centrifuge the solution, wash with water and alcohol CdSe quantum dots can be obtained after drying in an oven at 60° C. for 6 hour...

Embodiment 3

[0047] (1) Preparation of CdSe quantum dots: first weigh 0.4567g cadmium chloride (CdCl 2 2.5H 2 O) put into the there-necked flask, add 200mL deionized water to dissolve fully, and keep logical N 2 After half an hour, 0.341 mL of stabilizer methacrylic acid was added, and after thorough stirring, the pH of the solution was adjusted to 7 with 1 mol / L sodium hydroxide solution. Simultaneously weigh 0.3158g of selenium powder (Se) and 0.75g of sodium borohydride (NaBH 4 ) into a 10mL small beaker, add 7mL deionized water to dissolve completely, and pass N 2 Protect against oxidation, wait until the white precipitate appears and the precipitation is complete, use the dropper to absorb the supernatant liquid, drop by drop into the above three-necked flask solution, and react in a water bath at 80°C for 4 hours, take out the flask to cool naturally, centrifuge the solution, wash with water and alcohol CdSe quantum dots can be obtained after drying in an oven at 60° C. for 6 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com