Novel mixing and blending tank

A new technology of mixing and blending, which is applied in the direction of mixers, mixers with rotating stirring devices, mixer accessories, etc., can solve problems such as uneven mixing, failure to meet standards, inconvenient feeding, etc., to achieve convenient feeding, The material is mixed evenly and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

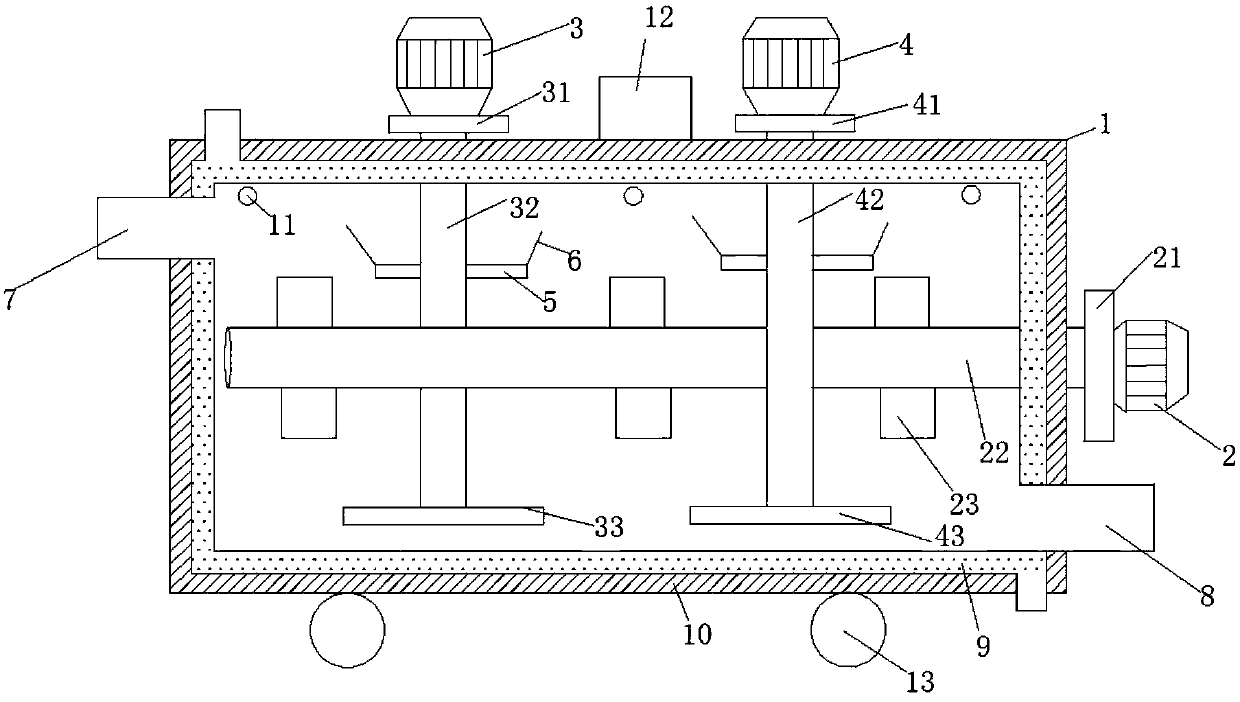

[0024] Such as figure 1 As shown, a new type of mixing and blending tank includes a tank body 1, a feed port 7 and a discharge port 8 respectively located on the left and right sides of the tank body 1, a first motor 2 located on the right side of the tank body 1, and a first transmission device 21, the first stirring shaft 22 located inside the tank, the first motor 2 is connected to the first transmission device 21, the first transmission device 21 is connected to the first stirring shaft 22, and the first The stirring shaft 22 is provided with 4-6 first stirring paddles 23; it also includes a second motor 3 and a second transmission device 31 positioned on the left side of the top of the tank body 1, and a second stirring shaft 32 positioned inside the tank body 1, so The second motor 3 is connected with the second transmission device 31, the second transmission device 31 is connected with the second stirring shaft 32, and the second stirring shaft 32 is provided with a sec...

Embodiment 2

[0027] Based on Example 1, such as figure 1 As shown, the outer wall of the tank body 1 is provided with a steam heating interlayer 9 , and the outer wall of the steam heating interlayer 9 is provided with an insulating layer 10 . If the prepared material needs to be heated, the material in the tank can be heated through the steam heating layer 9, and the insulation layer 10 plays a role of heat preservation, prevents the diffusion of hot gas, and enhances the heating effect. In addition to steam heating, the heating device can also be used to set electric heating wires in the interlayer for electric heating; at the same time, the insulation layer can also be vacuumed and insulation materials can be added for insulation.

Embodiment 3

[0029] A temperature sensor 11 is provided inside the tank body 1 , and the temperature sensor 11 is electrically connected to a temperature display 12 . The temperature sensor 11 inside the tank body 1 can monitor the temperature change in the tank body 1 from time to time, and display it through the temperature display 12 electrically connected to the temperature sensor 11, so as to understand the condition of the internal temperature of the tank body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com