Waste gas treatment equipment and process

A waste gas treatment equipment and waste gas treatment technology, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of high waste gas treatment cost, unreusable activated carbon, and expensive treatment cost, achieving low power and simple structure. , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

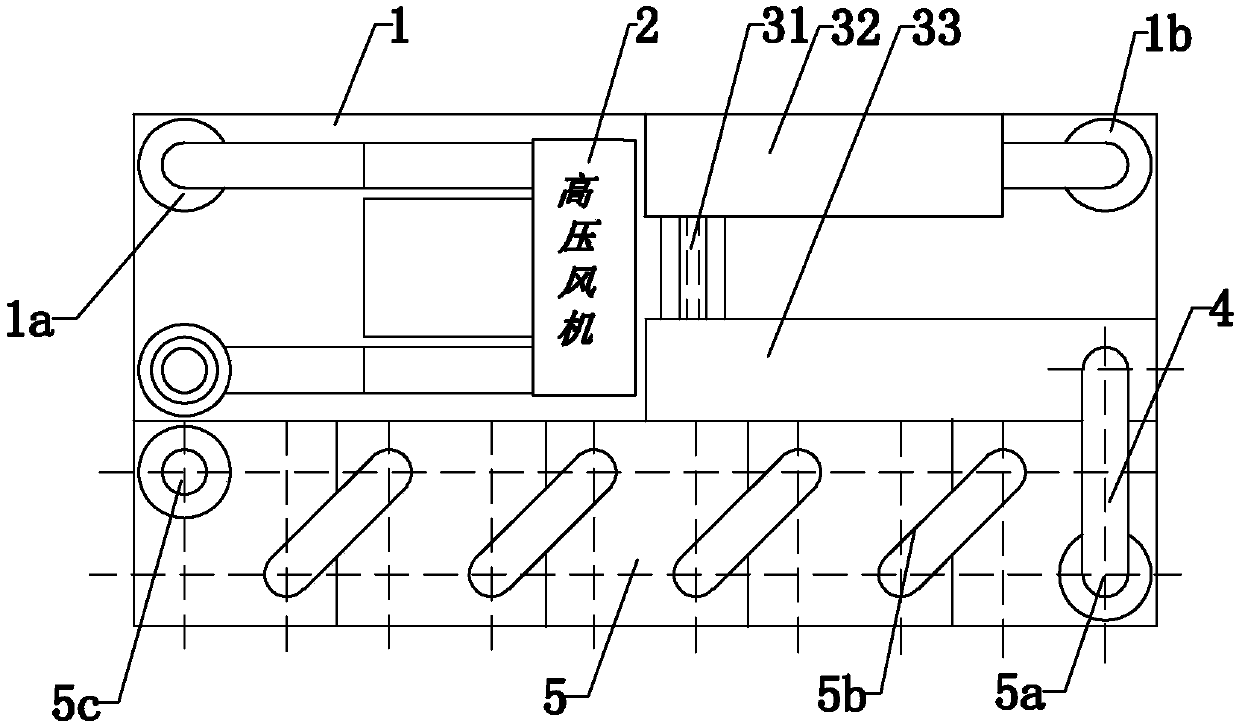

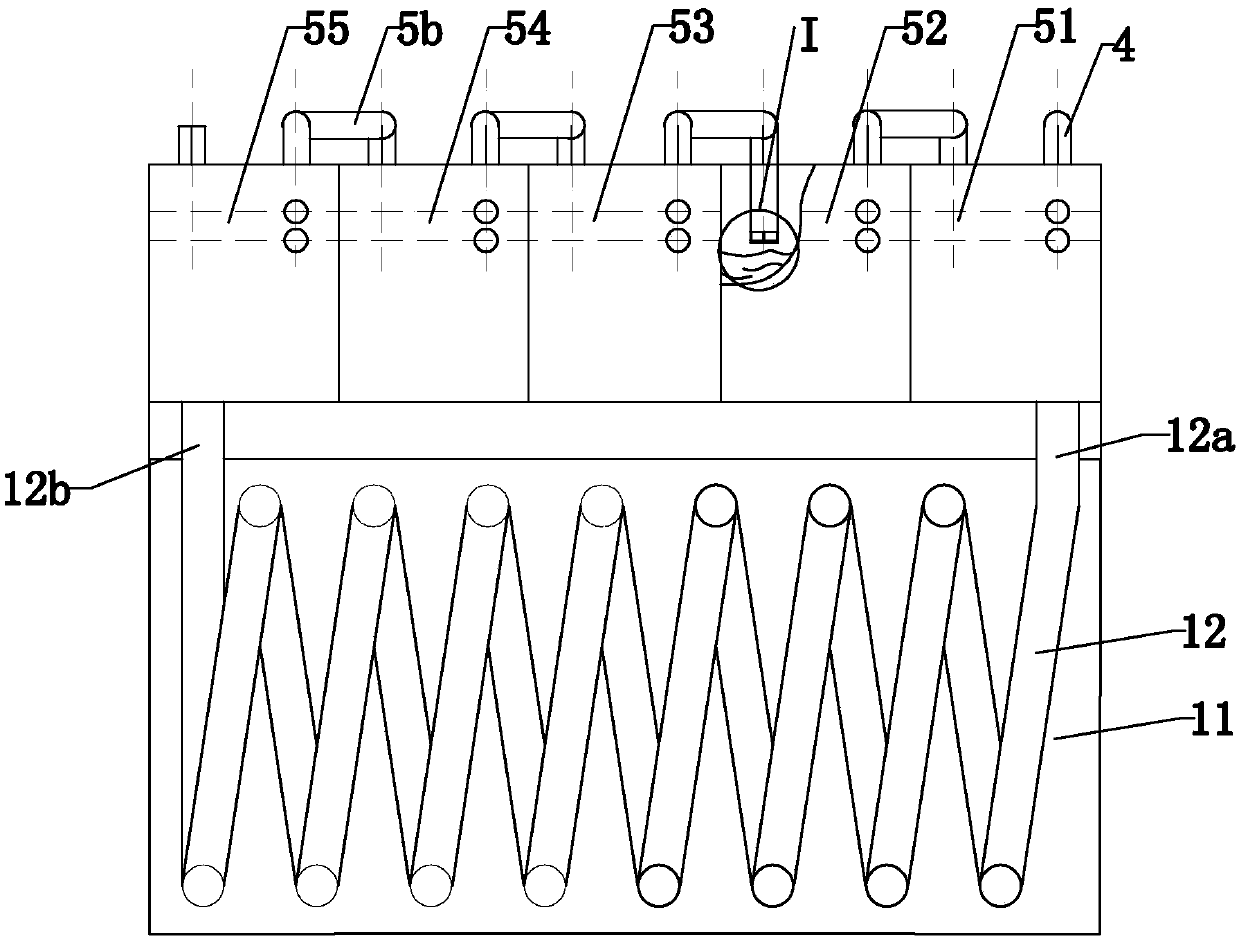

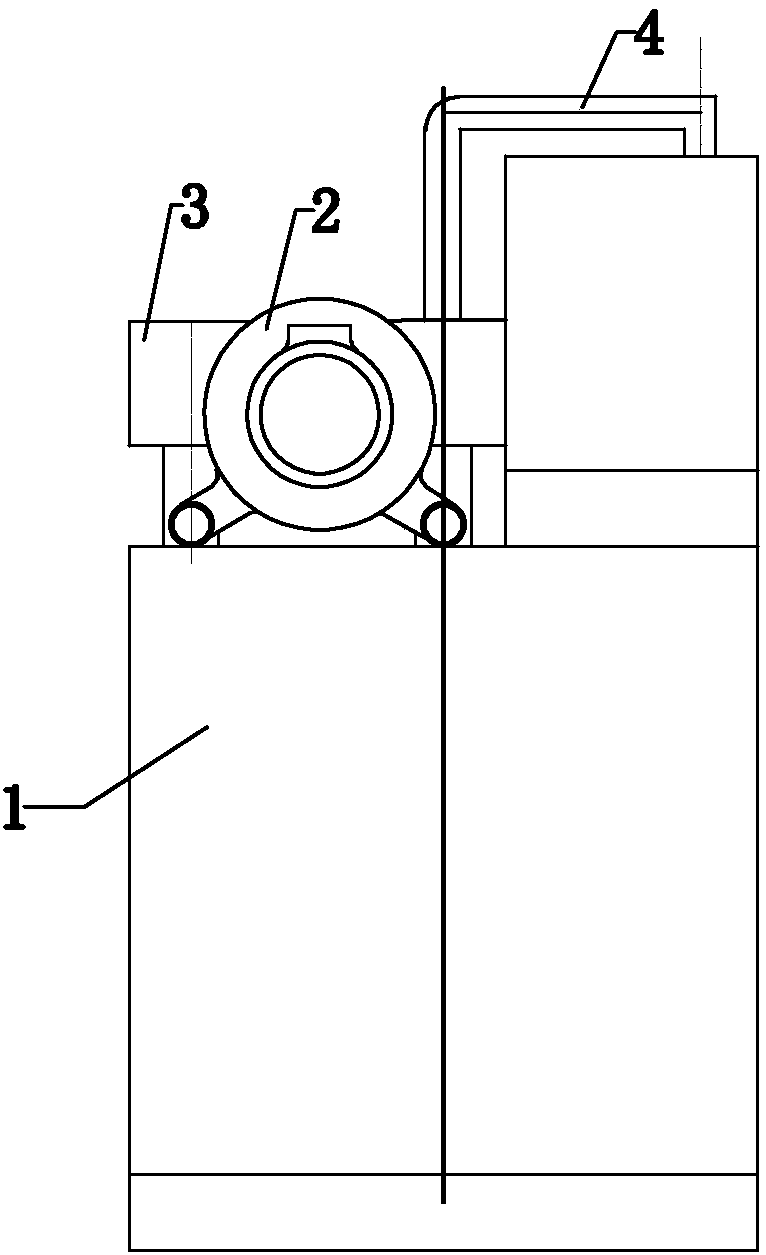

[0036] like figure 1 , figure 2 and image 3 As shown, the waste gas treatment equipment includes a high-pressure blower 2, a cooling device 1, a waste gas treatment pipeline and a micro-processing device 5 connected in sequence, and the waste gas inlet of the high-pressure blower 2 is directly connected with the waste gas outlet of the equipment in the factory or through exhaust and connectivity. The cooling device 1 is mainly composed of a cooling box 11 and a cooling coil 12 . The cooling spiral pipe 12 is arranged in the cooling box 11 , and its size is adapted to the cooling box 11 . The inlet and outlet of the cooling coiled pipe 12 are fixed and drawn out on the side wall at the top of the cooling box 11 , and the cooling coiled tube 12 is not connected to the inside of the cooling box 11 . The top of the cooling device 1 is provided with an exhaust gas inlet-1a and an exhaust gas outlet-1b, and the exhaust gas inlet-1a communicates with the exhaust gas outlet of t...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 is that: the air inlet of the high-pressure fan 2 is provided with a spraying device. The spraying device is used to cool down the exhaust gas and perform preliminary treatment on the exhaust gas to reduce the content of large particles and water-soluble substances in the exhaust gas for subsequent exhaust gas treatment.

Embodiment 3

[0048] like Image 6 As shown, the difference between this embodiment and Embodiment 1 is that: the gas outlet 5b of the exhaust gas treatment pipeline or the gas outlet 5b of the cooling device 1 or the gas outlet 5b of the micro-processing device 5 is provided with an ejector, and the ejector includes diameters in order Increased interior pipe 73, middle pipe 72, outer pipe 71, interior pipe 73 two ends open, and its inside is stuffed with loofah 74; Middle pipe 72 bottom opening and outer sleeve on the inner pipe 73, its top is closed. The outer tube 71 is overlaid on the inner tube 73 and wraps the middle tube 72. The bottom end of the outer tube 71 is sealed and fixedly connected to the side wall of the inner tube 73. The top of the outer tube 71 is provided with an opening to communicate with the outside world, and the air outlet 5b discharges The exhaust gas passes through the inner pipe 73 , the middle pipe 72 and the outer pipe 71 in sequence and then is discharged. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com