A mechanical device for returning crop straws to the field by cutting straws

A technology of crop straw and mechanical equipment, which is applied to crop processors, agricultural machinery and implements, cutters, etc., can solve the problems of running away moisture and affecting the sowing of crops in the next season, achieve high equipment efficiency, solve the problem of straw cutting size, The effect of small specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

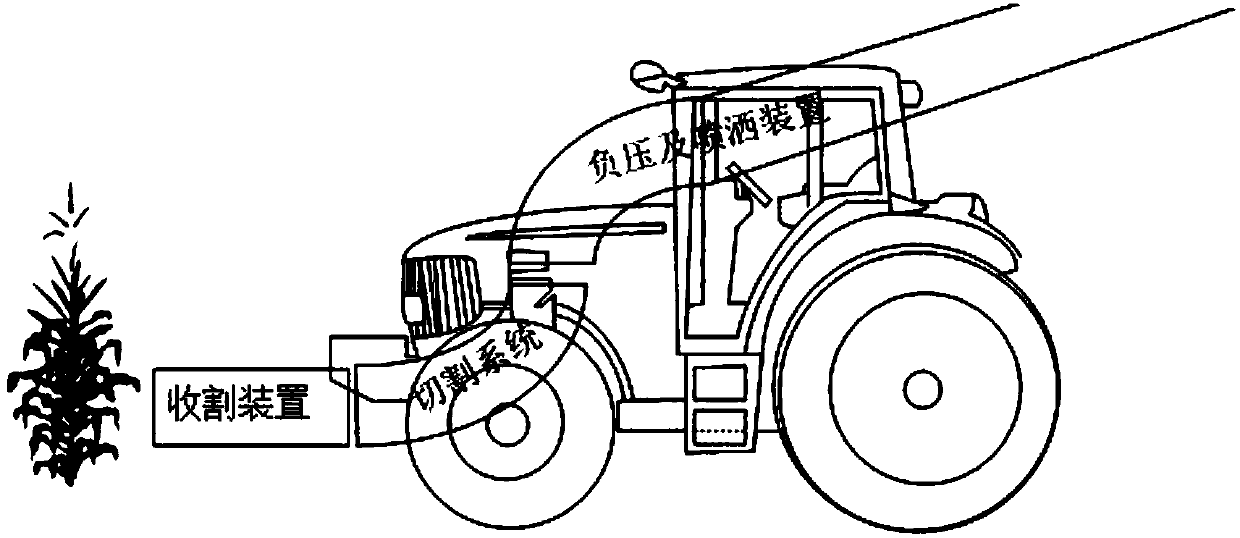

[0026] A kind of mechanical equipment of the present invention realizes returning crop straws to the field by cutting straws, such as figure 1 As shown, it includes a harvesting device, the harvesting device is connected with a cutting system, and the cutting system is connected with a negative pressure and a spraying device.

[0027] The harvesting device includes a supporting frame, on which a harvesting head, a guide feeding device, and an inlet 1 of a cutting system are sequentially arranged in the reverse direction of the advancing direction of the machine.

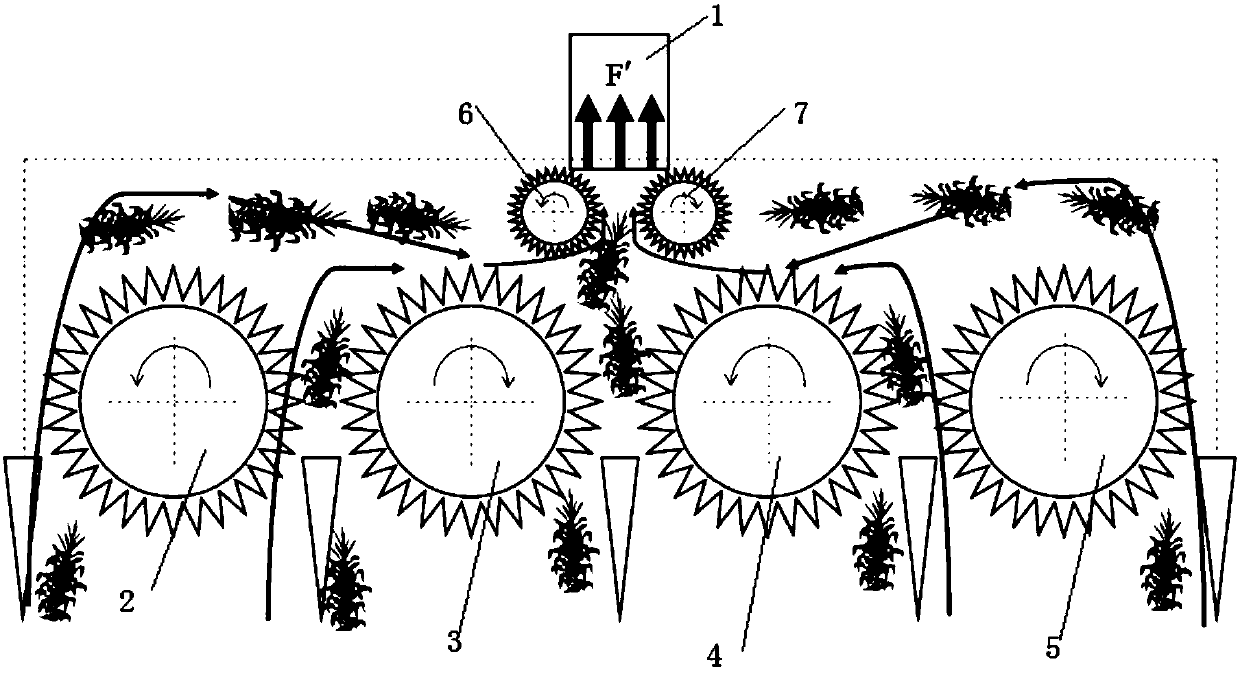

[0028] Such as figure 2 , image 3 As shown, the front end opening close to the forward direction of the machine on the support frame is provided with a middle separation guide frame 12 in the middle, and an edge guide frame 11 is respectively arranged on both sides, and the harv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com