A fast unloading and debonding device for a dump truck

A dump truck, fast technology, applied in the direction of loading and unloading vehicles, motor vehicles, vehicles with push plates, etc., can solve the problems of increased strength, human fatigue, unsuitable for large-scale, frequent dump truck loading and transportation, etc. Achieve the effect of not easy to break down and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

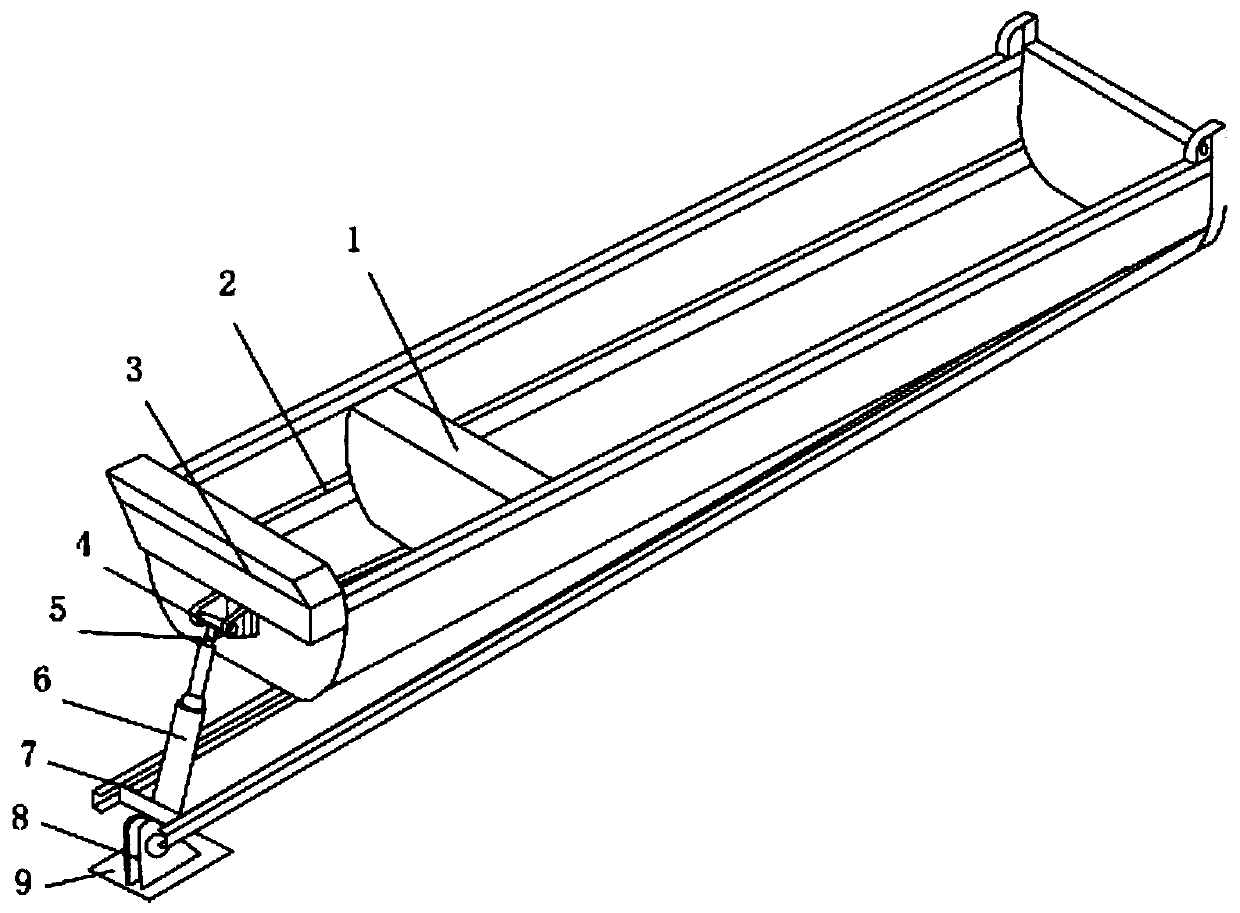

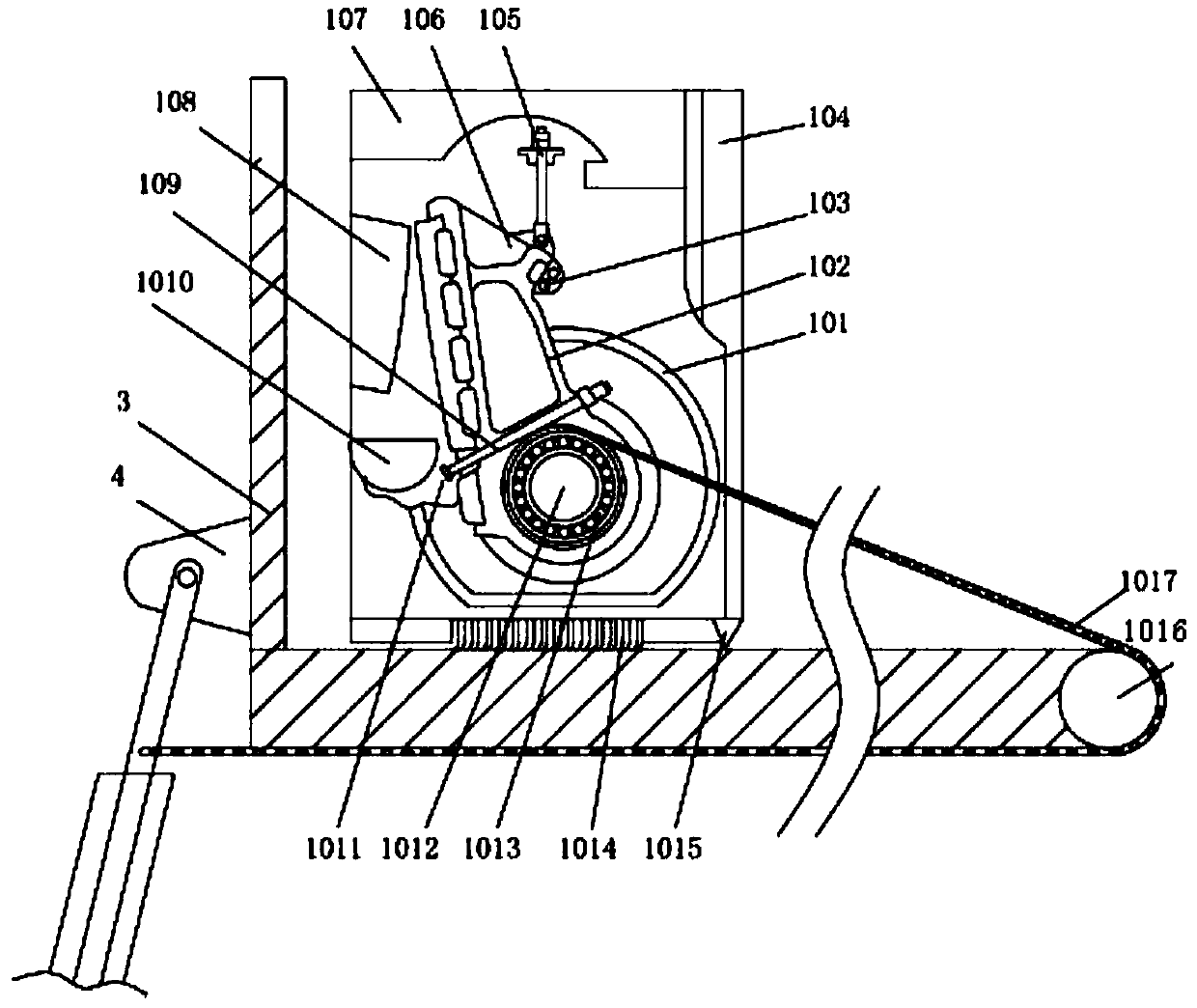

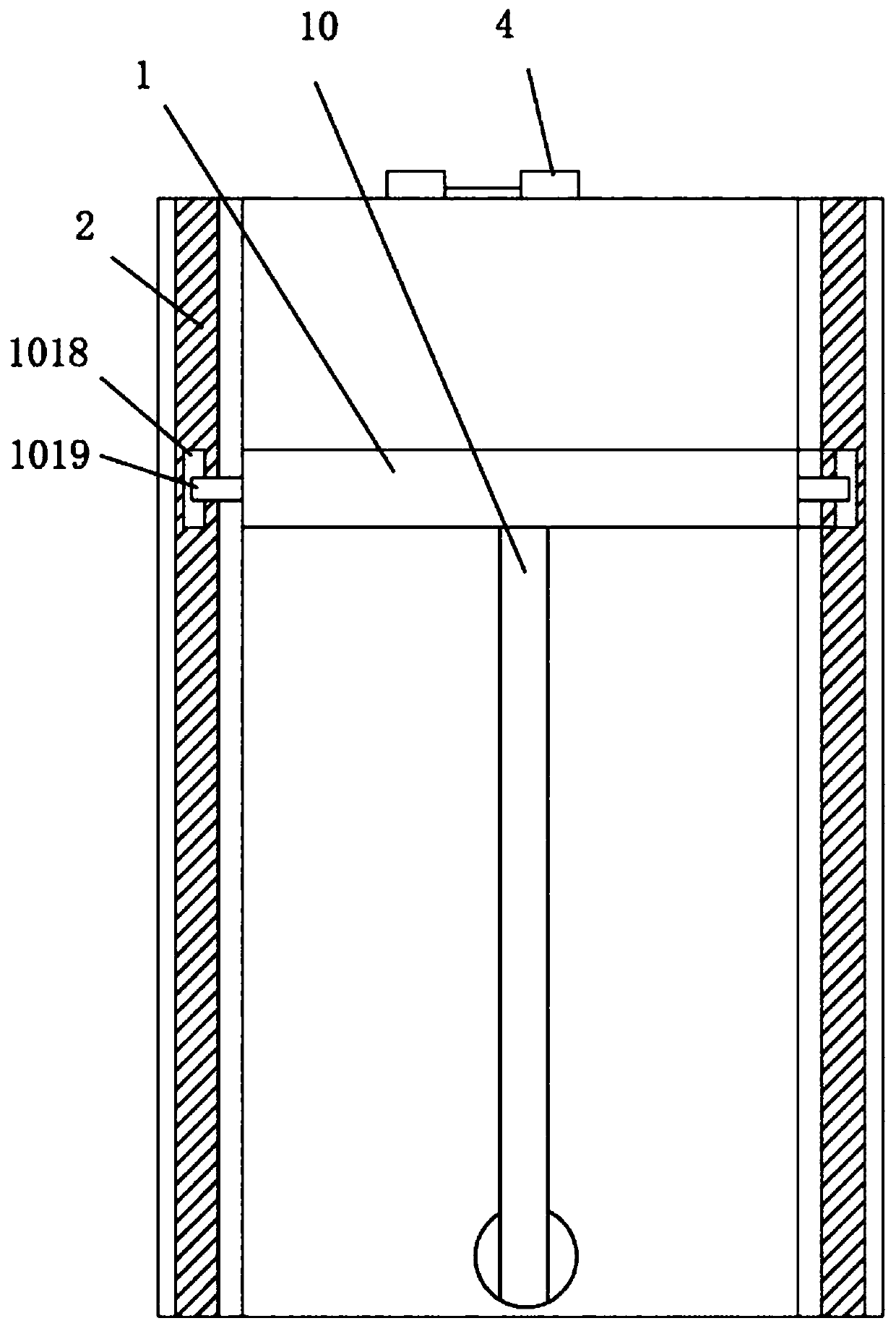

[0022] see Figure 1-Figure 5 , the present invention provides a quick unloading and debonding device for a dump truck, the structure of which includes a material removal mechanism 1, a sliding groove 2, a box body 3, a first fixing lug 4, a chain fixing hole 5, a hydraulic cylinder 6, and a placement frame 7 , the second fixed lug 8, the base plate 9, the cover plate 10, the two sides of the inner wall of the box body 3 are fixedly provided with sliding grooves 2, the material removal mechanism 1 is located inside the box body 3, and the material removal mechanism 1 and the sliding groove 2 adopt a clearance fit, and the first fixed lug 4 is welded vertically on one end of the box body 3, and the box body 3 is installed on the placement frame 7 without the end of the first fixed lug 4 Hinge connection, the other end of the placement frame 7 is provided with a hydraulic cylinder 6, the upper and lower ends of the hydraulic cylinder 6 are respectively movably connected to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com